Fast-discharge valve of air braking chamber for vehicle

A technology of automobile braking and air chamber, which is applied in the direction of control valves, air release valves, brakes, brake components, etc. In case of failure and other problems, it achieves the effect of simple structure, convenient and simple installation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

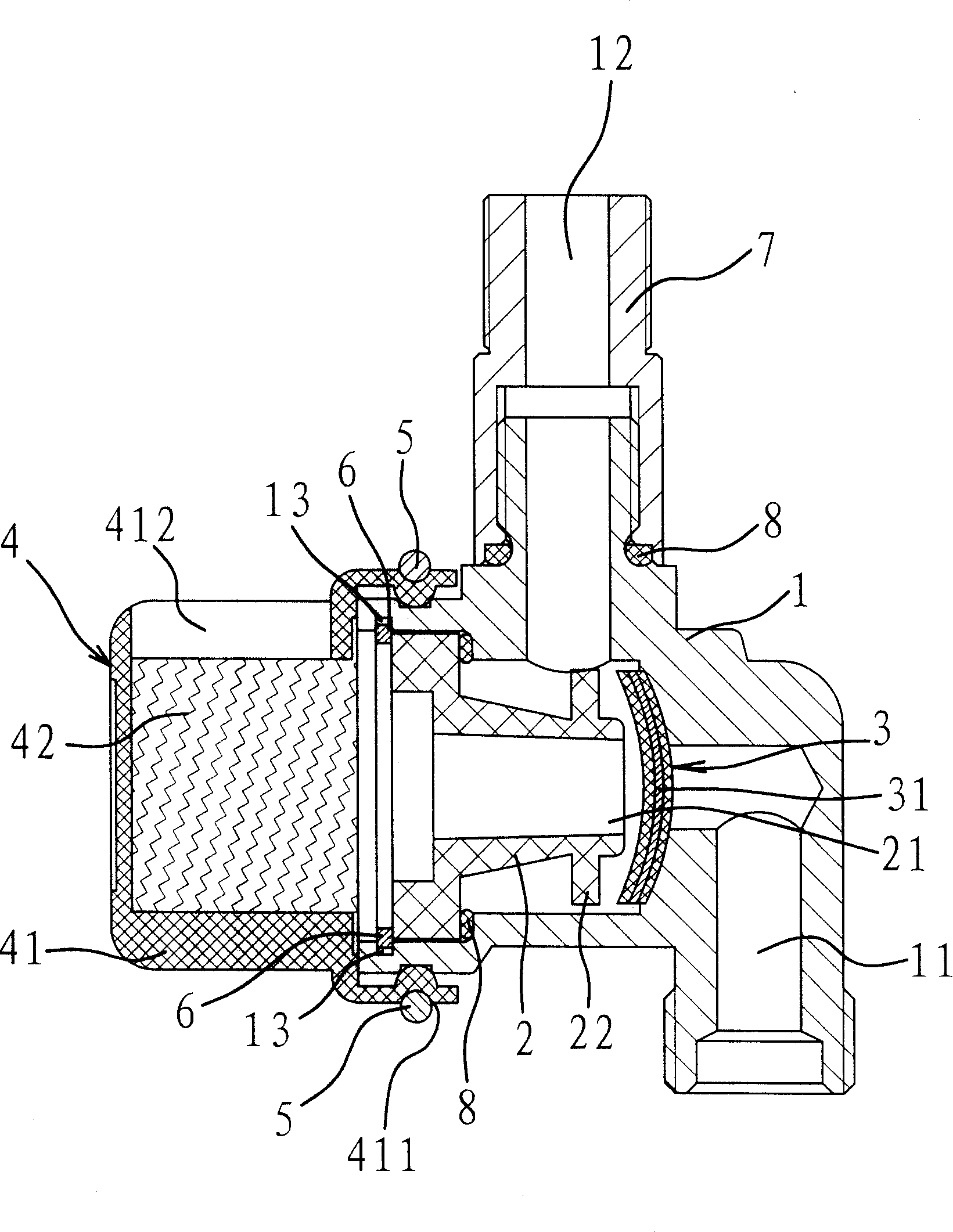

[0019] As shown in the figure, the quick release valve of the brake air chamber of this automobile is installed in the brake system of the automobile. It is composed of valve body 1, valve seat 2, valve plate 3, muffler 4 and connecting bolt 7.

[0020] The valve body 1 is a three-way pipe with a cavity inside. Two of the nozzles of the valve body 1 are an air inlet 11 and an air outlet 12 respectively, and the cavity connects the air inlet 11 and the air outlet 12. An inner ring groove 13 is opened at the end of the other nozzle, and the inner ring groove 13 is recessed on the inner surface of the valve body 1. The valve seat 2 is installed in the cavity of the valve body 1, and the circlip 6 installed in the inner ring groove 13 blocks the end of the valve seat 2 so that the valve seat 2 is fixed in the valve body 1. In this embodiment, a sealing gasket 8 for sealing is installed between the valve seat 2 and the inner surface of the valve body 1.

[0021] The valve seat 2 is cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com