Security paper or board product and security package

A security paper and cardboard technology, applied in the field of security packaging, can solve the problems of expensive manufacturing, easy counterfeiting, and difficulty, and achieve the effect of low cost, low cost, and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

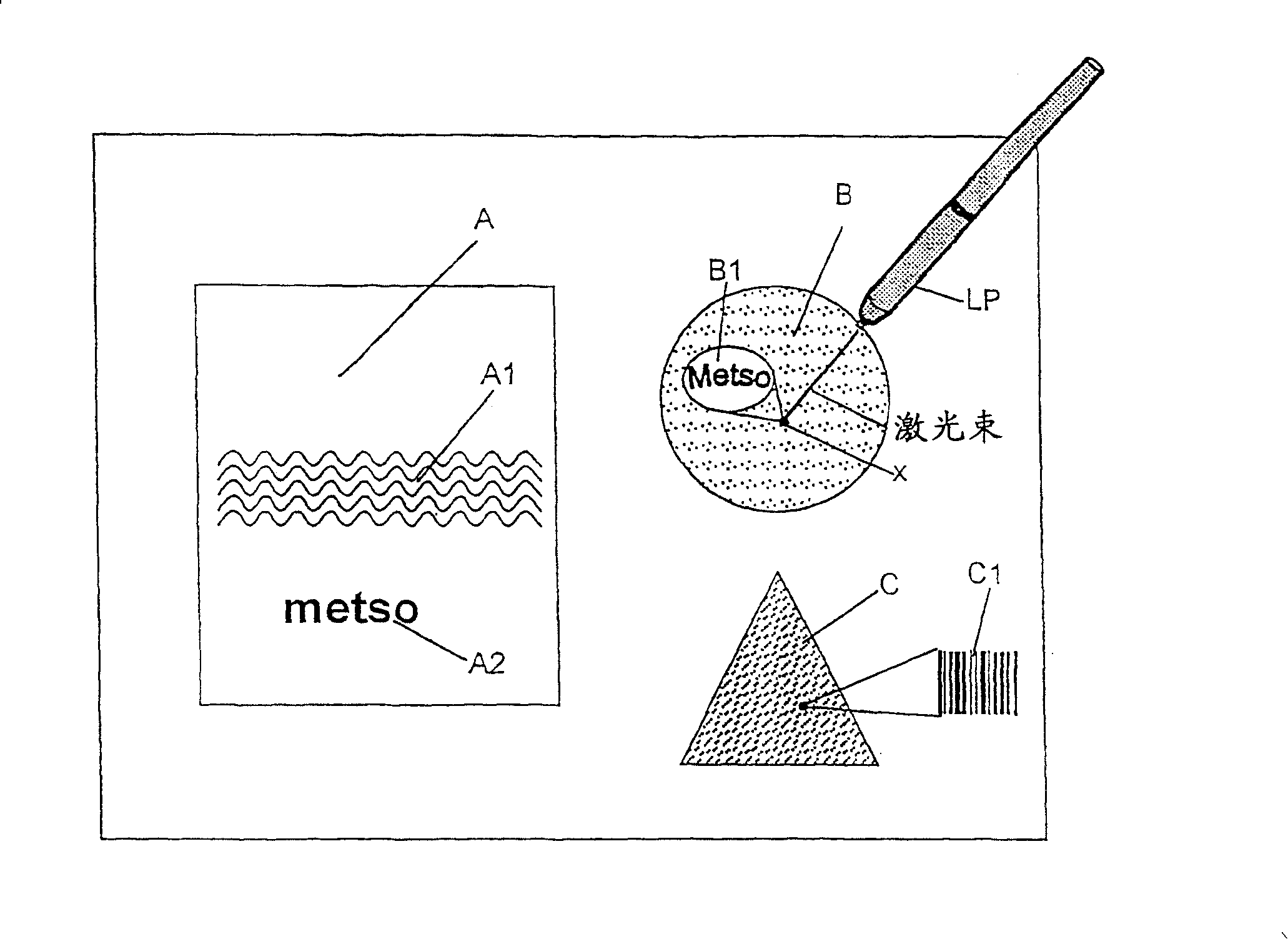

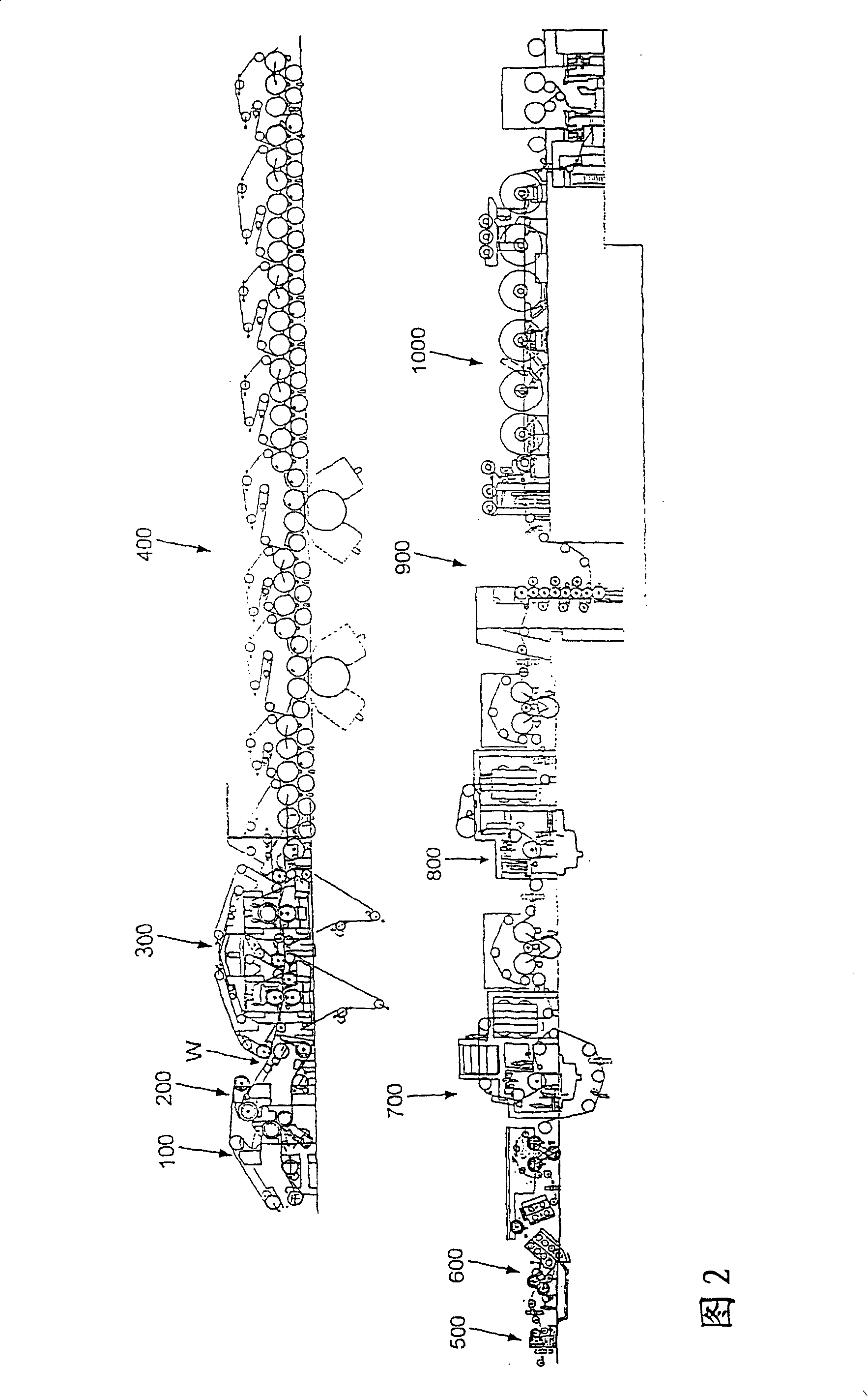

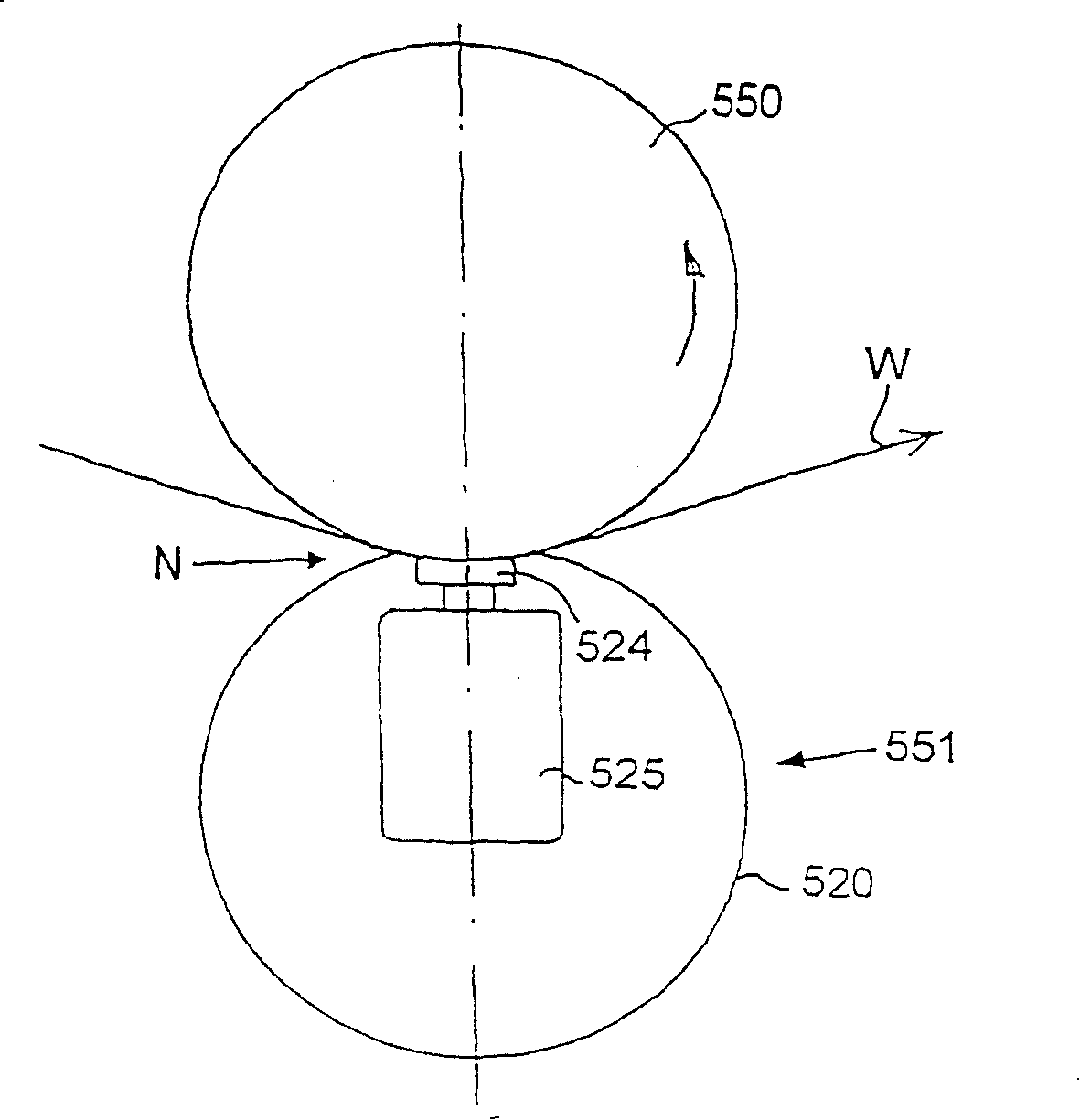

[0032] Embedding security elements into packaging materials during papermaking requires spacers containing multiple diffractive structures on the embedding surface. Diffractive structure spacers are elements capable of embedding diffractive structures in desired materials, such as paper or cardboard or packaging material webs. The diffractive structured spacer is preferably arranged in a matrix suitably distributed on an embedded surface, such as a roll in a paper machine or printing unit as described below. Because the desired diffractive structure of the spacer matrix is first obtained by electron beam, laser beam, X-ray beam, ion beam, or obtained by coating a suitable resist on a suitable substrate by other lithographic methods. This microscopic surface relief profile is formed on the resist protection layer. After this, the surface is converted to a negative surface profile in nickel by electroplating. This creates secondary and tertiary power generating pads for a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com