Apparatus for packing free terminal convolutions of spring assembly used in mattress

A technology of spring assembly and winding turns, applied in mattresses, spring mattresses, applications, etc., can solve problems such as the deterioration of the elastic force of the coil spring 115 and the damage to the cushion member.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The preferred embodiments of the present invention will now be described in detail, examples of which will be illustrated in the accompanying drawings.

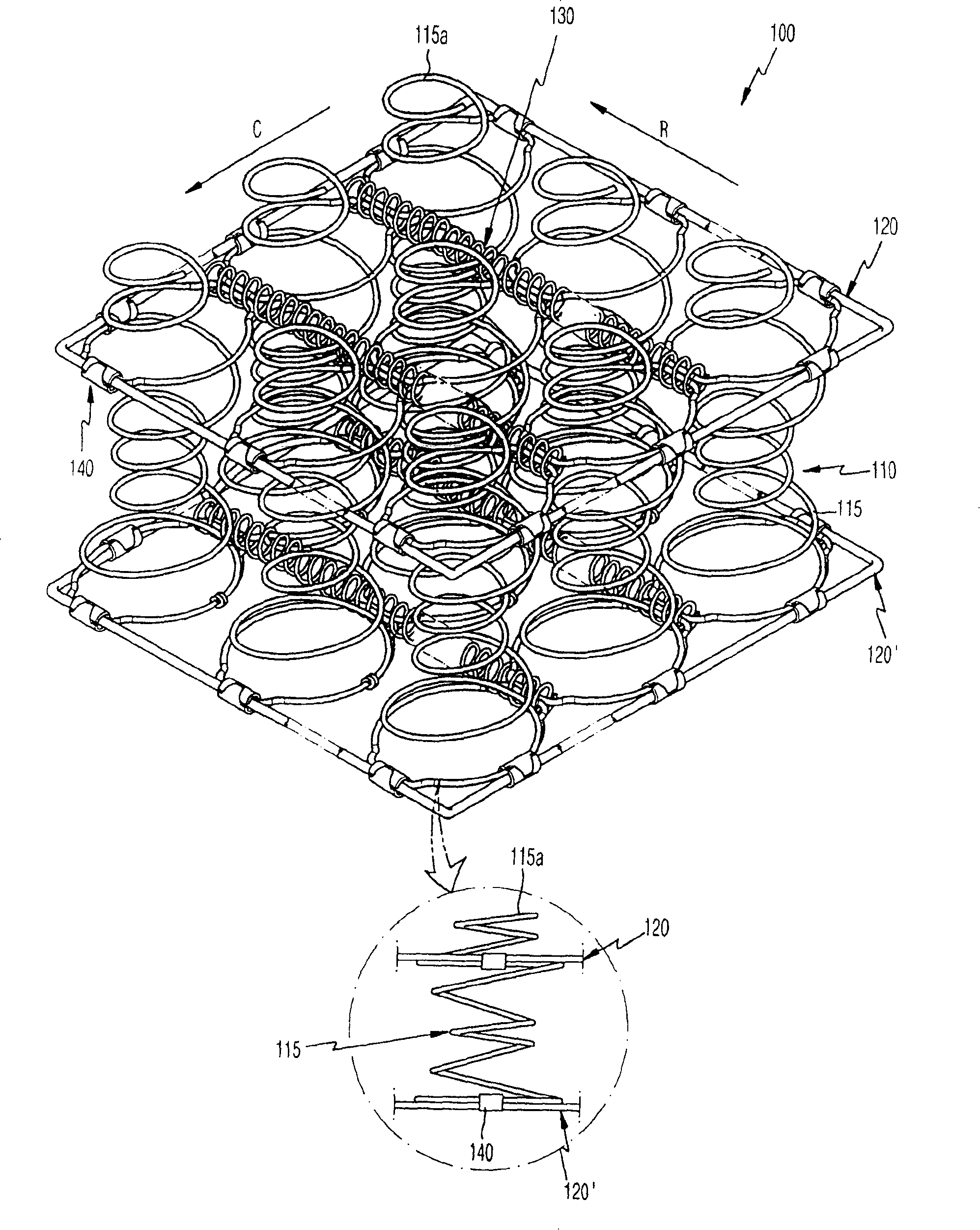

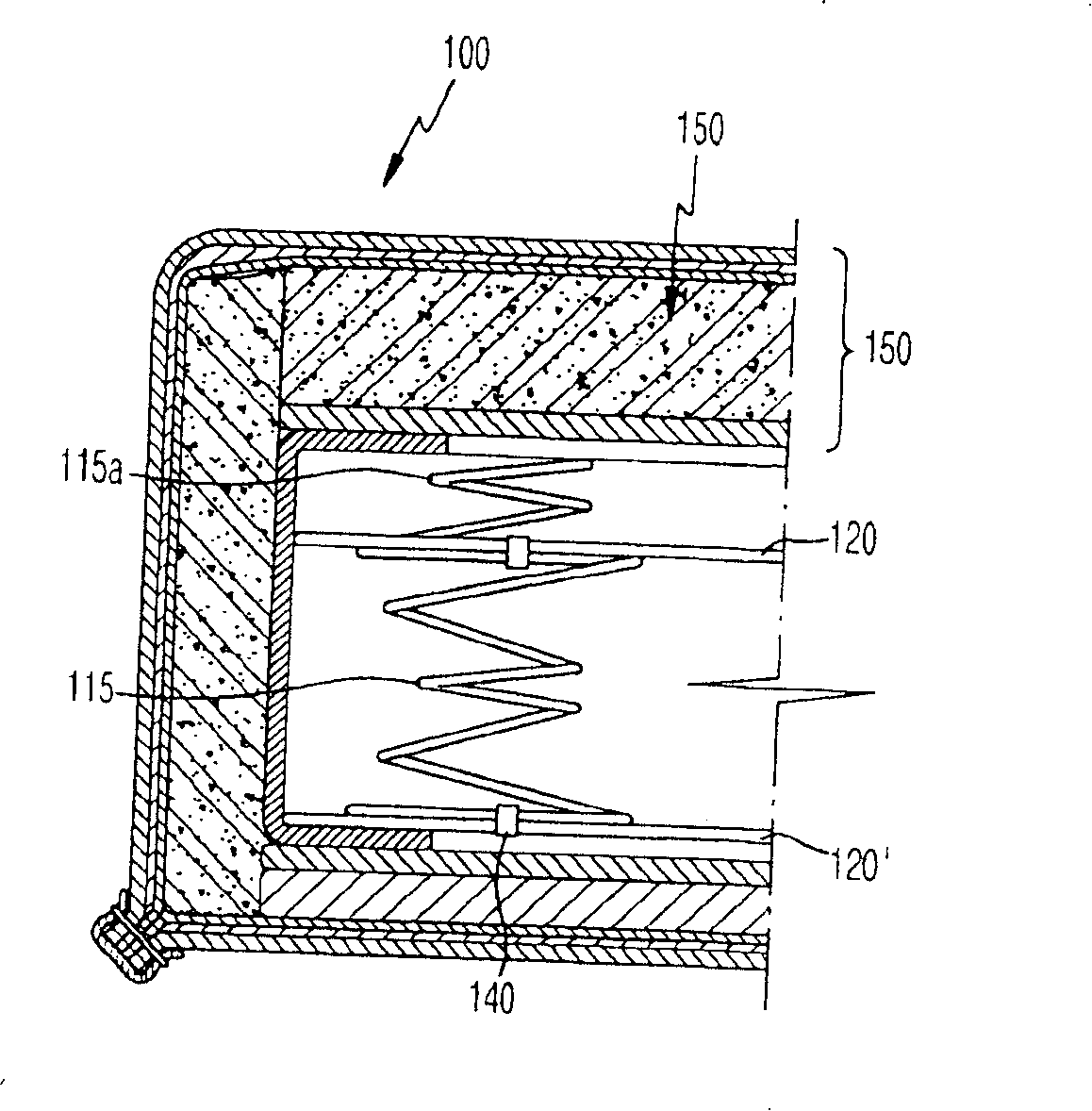

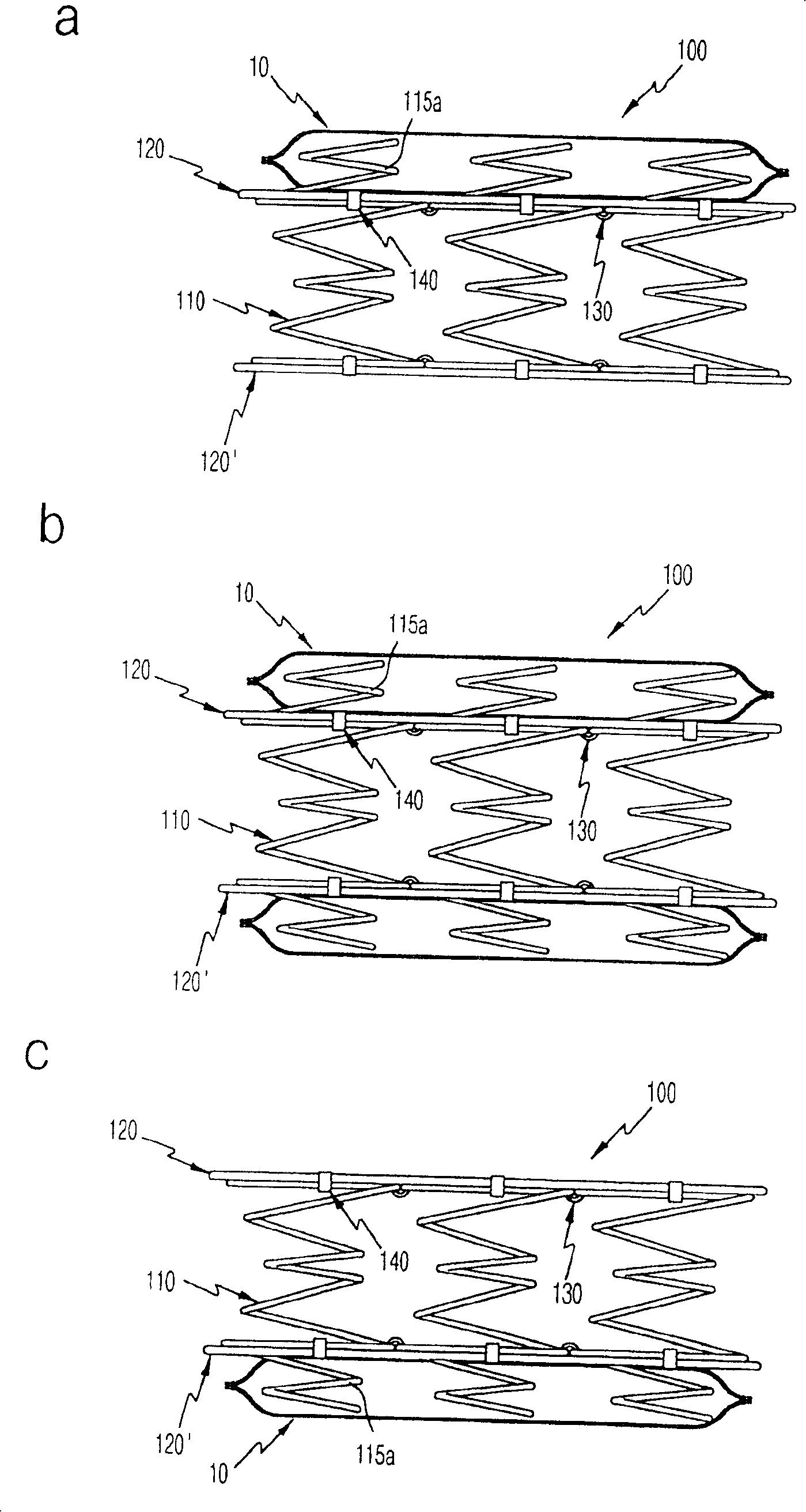

[0018] Figure 3 to Figure 8 Respectively are sectional views according to a preferred embodiment of the present invention, the spring assembly is covered with non-woven fabric. Figure 9 and Figure 10 Respectively are sectional views according to a preferred embodiment of the present invention, the spring assembly is covered with non-woven fabric. Figures 11 to 14 Respectively, a sectional view of a preferred embodiment according to the invention, with the polyurethane foam molding placed on the spring assembly. The outermost coil spring 115 of the spring array 110 is fixed in the space between the upper and lower boundary steel wires 120 and 120' by means of the fixing sum 140, and the helical coil 130 is placed between the upper and lower parts of the spring arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com