Stator iron core pressing device with sextant floating press head

A stator core, floating technology, applied in the manufacture of stator/rotor body, etc., can solve the problem of uneven pressing coefficient and other problems, and achieve the effect of good pressing effect, high yield and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

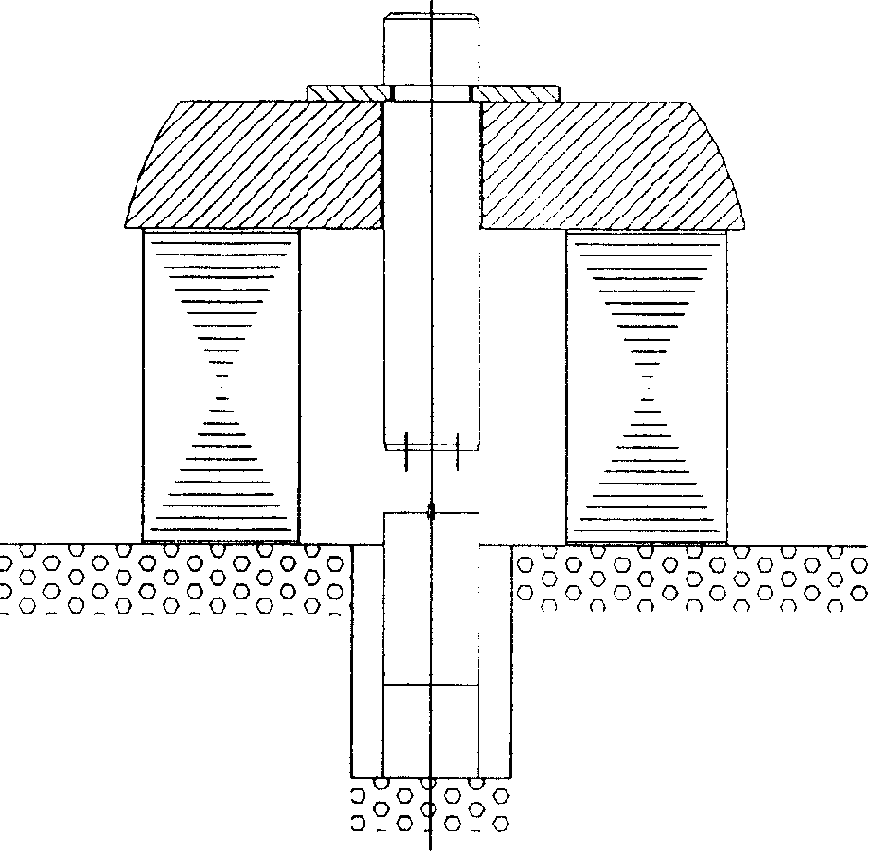

[0016] figure 1 This is the structural diagram of the existing stator core press-fitting equipment, which uses an integral indenter, which can easily cause the problem of unbalanced core press-fit coefficients and affect the quality and life of the product.

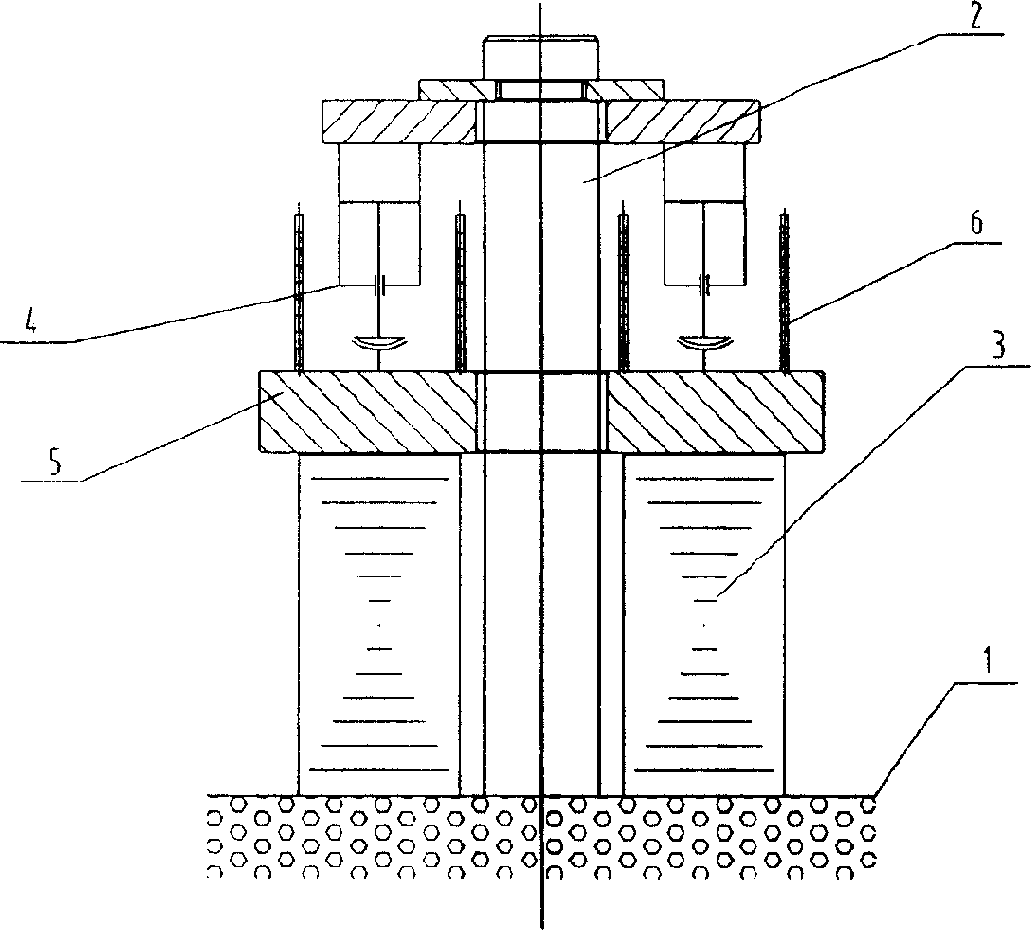

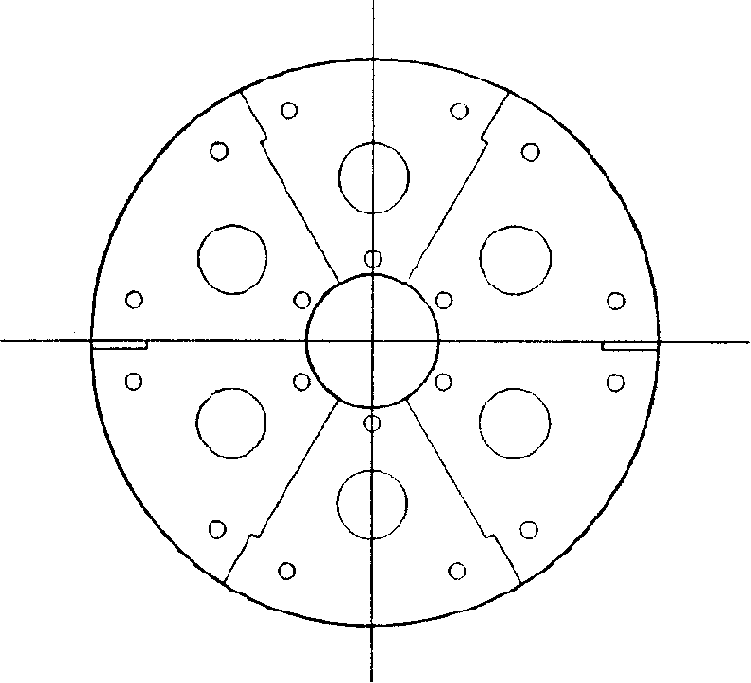

[0017] figure 2 The structural diagram of the present invention is given. On the workbench 1, a positioning column 2 is provided, on which the iron core laminations 3 are set. On the top of the positioning column 2 is a hydraulic control device 4, that is, a hydraulic cylinder. The evenly distributed floating pressure divider 5 constitutes the pressure head of the equipment. Each floating pressure divider 5 is equipped with a pressure cylinder and connected with its corresponding hydraulic control device 4. The floating pressure divider 5 is connected to the core laminations. The contact surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com