Sealing device of charging and discharging ends of rotary cylindrical type device

A technology of material inlet and outlet and end sealing, which is applied in the direction of mechanical equipment, engine sealing, engine components, etc., can solve the problems of reduced operating rate, equipment seal failure, cylinder air leakage, etc., to improve operating rate, ensure tight fit, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

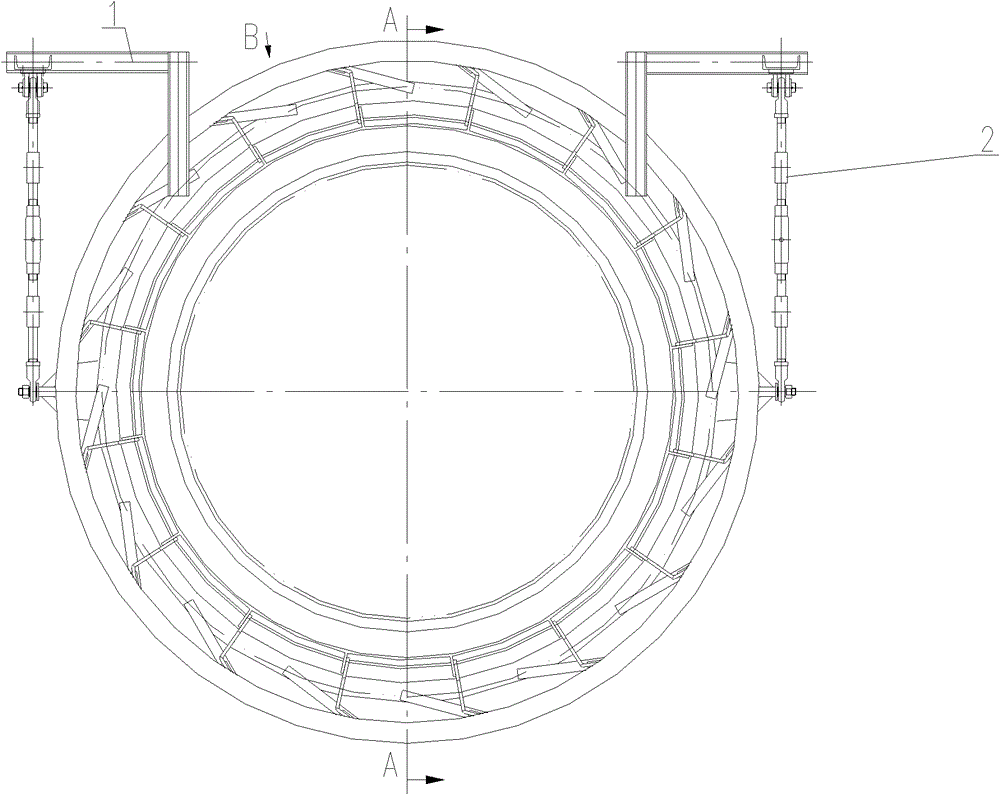

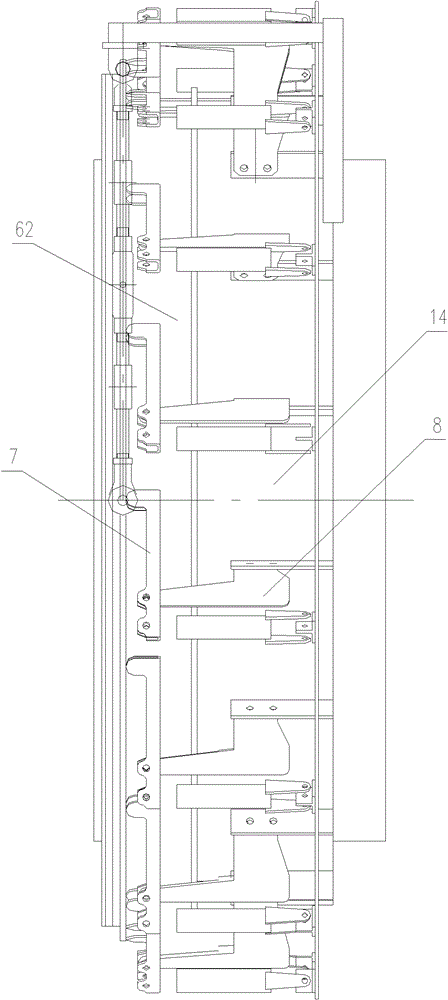

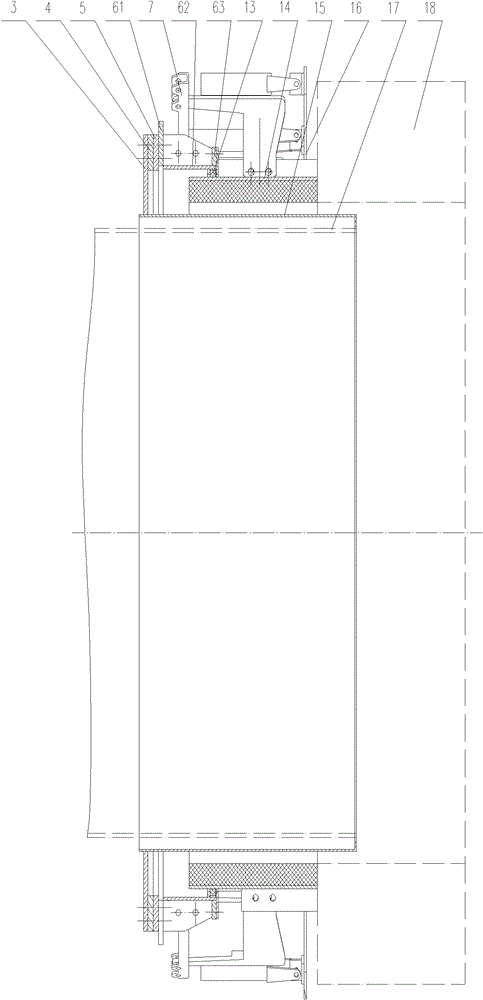

[0018] See Figure 1 to Figure 5 , a rotary cylinder type equipment inlet and outlet sealing device, including a rotating sleeve 15 fixed on the rotating cylinder 17 and a fixed sleeve 14 fixed on the inlet and outlet end 18 of the equipment, the fixed sleeve 14 is set on the On the outside of the rotating sleeve 15, a movable supporting ring 3 is fixedly connected to the rotating sleeve 15, and a moving friction block 4 is fixedly connected to the outer end surface of the moving supporting ring 3; The static support ring includes a cylinder 62 and an inner plate 61 and an outer plate 63 affixed thereto. The inner end surface of the inner plate 61 is fixed with the static friction block 5 adapted to the dynamic friction block 4 . The static ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com