Pressure connection detection circuit for induction heating type cooker

A heating pot and induction technology, applied in induction heating, induction heating devices, pressure cookers, etc., can solve the problems of guide switch action sensitivity deviation, action point error, error, etc., to improve product reliability, improve detection reliability, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Referring to the accompanying drawings, the pressure connection detection circuit using the induction heating pot of the present invention will be described in detail.

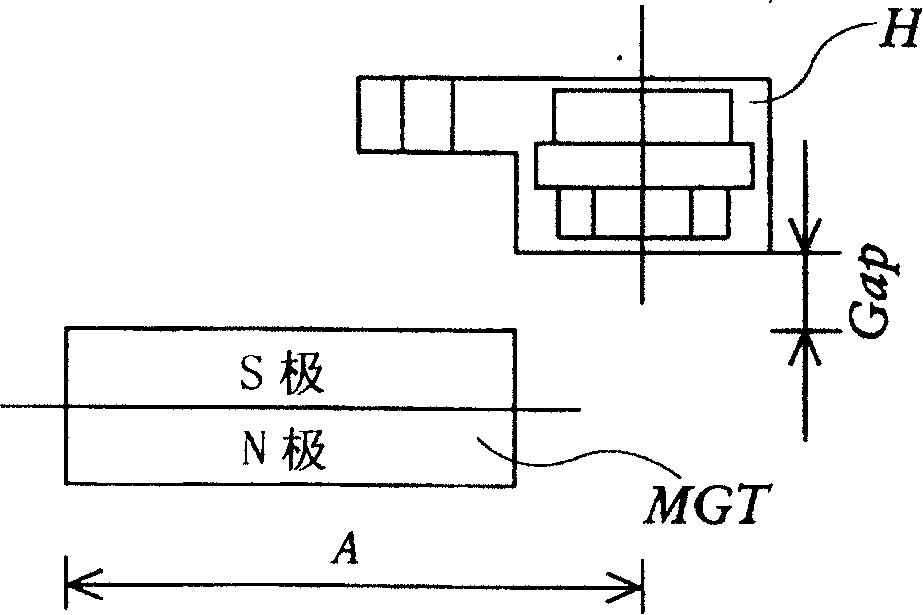

[0036] image 3 It is a structural diagram for detecting whether the induction heating pan of the present invention is in a pressure connection state.

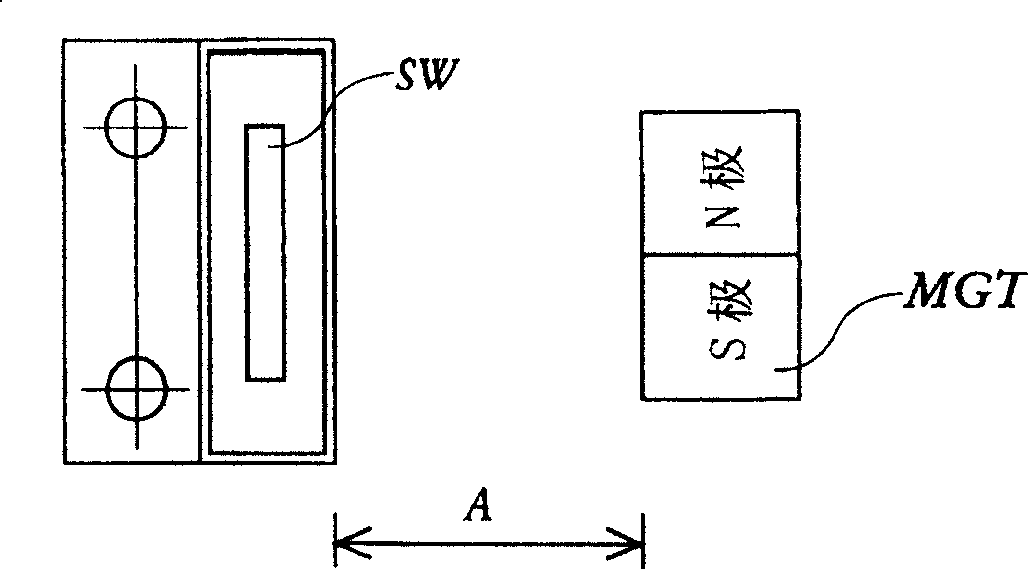

[0037] In order to detect whether the lid is in a pressure connection state, the induction heating pan of the present invention is characterized by using a Hall IC H. When the magnet MGT is close to the lower end of the Hall integrated circuit H, the Hall integrated circuit is turned on. The above-mentioned deviation of the magnet MGT and the operation error caused by the H characteristic of the Hall IC are affected by the above-mentioned vertical distance (gap) and the horizontal size of the magnet, so it is the same as the conventional product. But due to image 3 With the structure shown, since the above-mentioned deviation in the horizontal direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com