Splice bamboo plate and its making method

A production method and a technology for assembling boards, which are applied in the directions of manufacturing tools, veneer manufacturing, and wood veneer joining, etc., can solve the problems of slow processing speed, high production cost, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

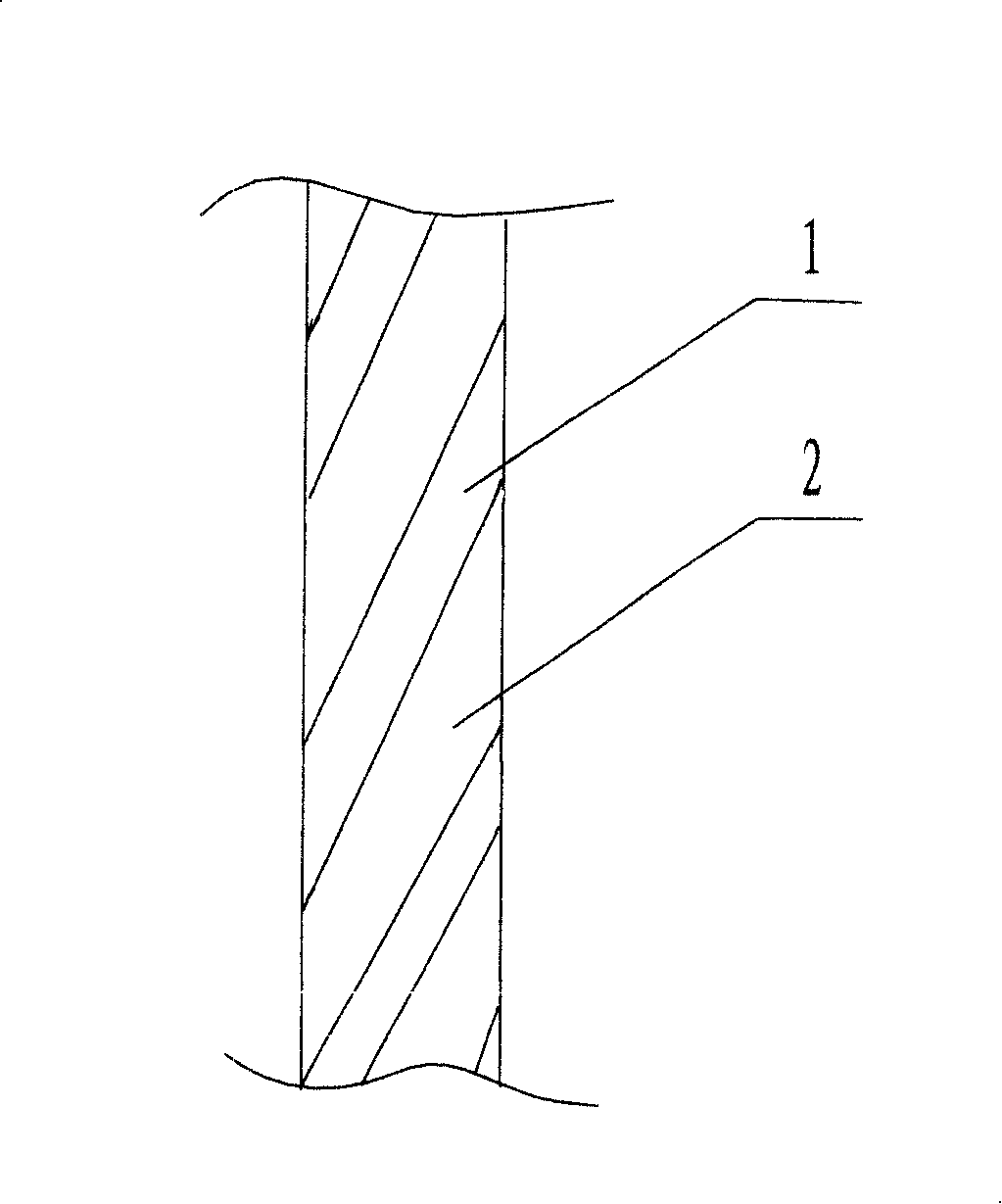

[0027] 1) Rough blanking: the bamboo tube with a diameter of 30 cm after felling is cut into bamboo sections according to the required length, and then the tube-shaped bamboo section is longitudinally cut into arc-shaped bamboo strips of 3.2 cm;

[0028] 2) remove the bamboo joints of the arc-shaped bamboo strips;

[0029] 3) Heat the arc-shaped bamboo strips from which the bamboo joints have been removed with 200°C steam for half an hour to soften them completely;

[0030] 4) adopt existing flattening treatment technology, the upper surface of the fully softened bamboo strip is pressurized, and the radian of the upper and lower surfaces of the bamboo strip is flattened, so that the upper and lower surfaces of the bamboo strip are smooth;

[0031] 5) when the bamboo strips after the flattening process are not dry and the texture is still soft, use a planer in time to plan the upper and lower sides of the bamboo strips;

[0032] 6) Place the planed and planed bamboo strips in ...

Embodiment 2

[0037] 1) Rough blanking: the bamboo tube with a diameter of 33 cm after felling is cut into bamboo sections according to the required length, and then the tube-shaped bamboo section is longitudinally cut into arc-shaped bamboo strips of 8.2 cm;

[0038] 2) remove the bamboo joints of the arc-shaped bamboo strips;

[0039] 3) Boil arc-shaped bamboo strips in hot water at 100°C for 3 hours. Due to the long boiling time, the bamboo strips after cooking are not only completely softened, but also treated with insect repellent and bleaching;

[0040] 4) adopt existing flattening treatment technology, the upper surface of the fully softened bamboo strip is pressurized, and the radian of the upper and lower surfaces of the bamboo strip is flattened, so that the upper and lower surfaces of the bamboo strip are smooth;

[0041] 5) Dry the bamboo strips with flat upper and lower surfaces in a dryer at 50°C until they are fully dry, remove the moisture contained in the bamboo strips, and...

Embodiment 3

[0046] 1) Rough blanking: the bamboo tube with a diameter of 33 cm after felling is cut into bamboo sections according to the required length, and then the tube-shaped bamboo section is longitudinally cut into arc-shaped bamboo strips of 6.5 cm;

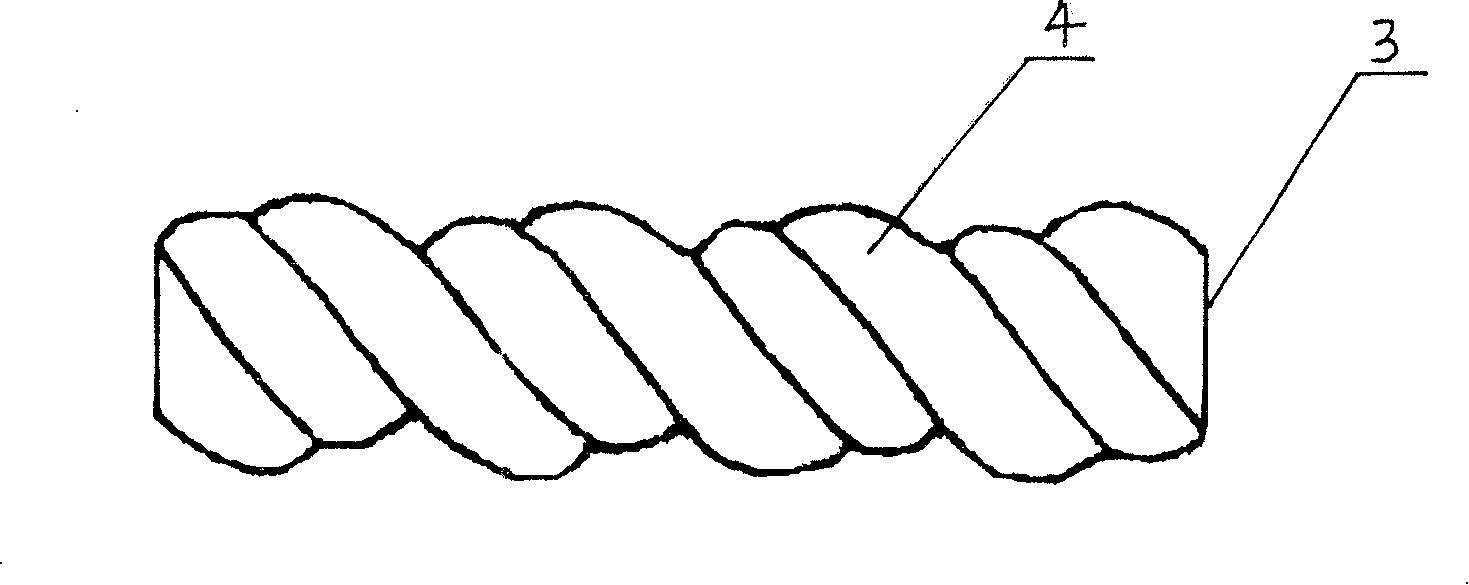

[0047] 2) Use the arc-shaped bamboo strips with figure 2 The flattening machine of the roller is flattened so that the radians of the upper and lower surfaces of the bamboo strips are flattened to obtain smooth bamboo strips on the upper and lower surfaces; Flat top roll 3 and bottom roll, the structure of top roll 3 is as figure 2 As shown, the surface is provided with continuous thread-like distribution and arc-shaped protrusions 4 in cross-section; during operation, only the arc-shaped bamboo strips need to be placed between the upper and lower rollers of the bamboo strip flattening machine, and let The bamboo white surface of the bamboo strip is opposite to the upper roller 3 with protrusions 4 on the surface, and the radian o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com