Method and apparatus of reconnecting for air-flow spinner

A technology of an air spinning machine and a piecing device, which is applied to the piecing device, spinning machine, open-end spinning machine, etc., to achieve the effect of reliable cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

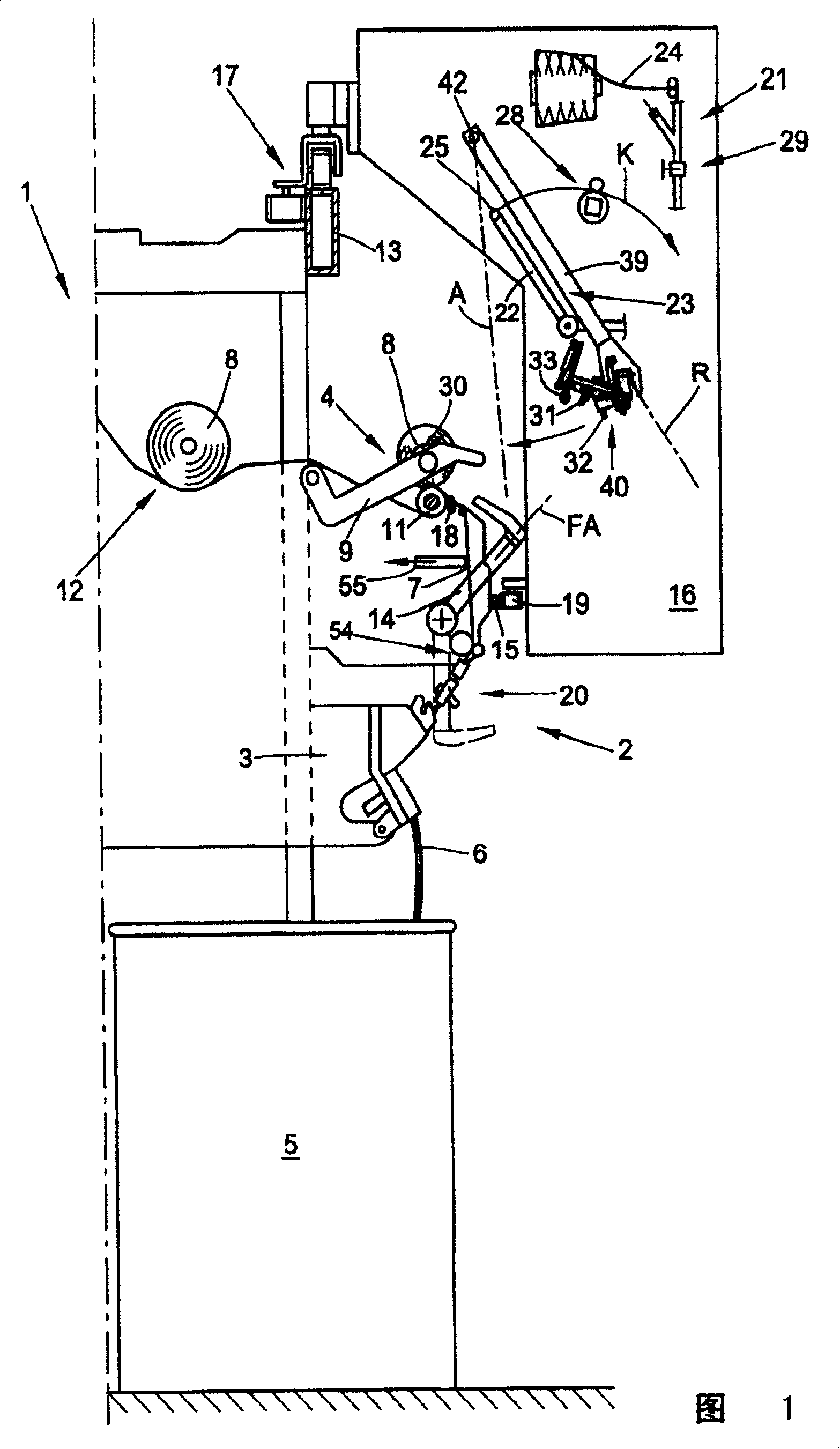

[0035]FIG. 1 shows one half of an air spinning machine known per se and is denoted by 1 . Such an air spinning machine has a plurality of working positions 2, each of which is equipped with a spinning device 3 and a winding device 4.

[0036] The fiber sliver 6 fed to the spinning can 5 is spun into a yarn 7 in the spinning device 3 , which is wound into a cross-wound bobbin 8 on the winding device 4 . As shown in the figure, the winding device 4 is respectively equipped with a creel holder 9 rotatably holding an empty bobbin 10 or a cross-wound bobbin 8 and a drum 11 driving the cross-wound bobbin.

[0037] Furthermore, each working position 2 has a yarn traversing device 18 , a working position's own suction nozzle 14 and a working position's own piecing device 20 . That is, all working positions 2 are equipped to automatically eliminate yarn breaks.

[0038] Furthermore, the air spinning machine 1 has a bobbin transport device 2 for removing the cross-wound bobbins 8 comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com