Piston compressor

A piston type and compressor technology, which is applied in compressors, piston pumps, liquid displacement machines, etc., and can solve problems such as jamming, leakage, and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Several embodiments of the present invention are described in detail below with reference to the accompanying drawings.

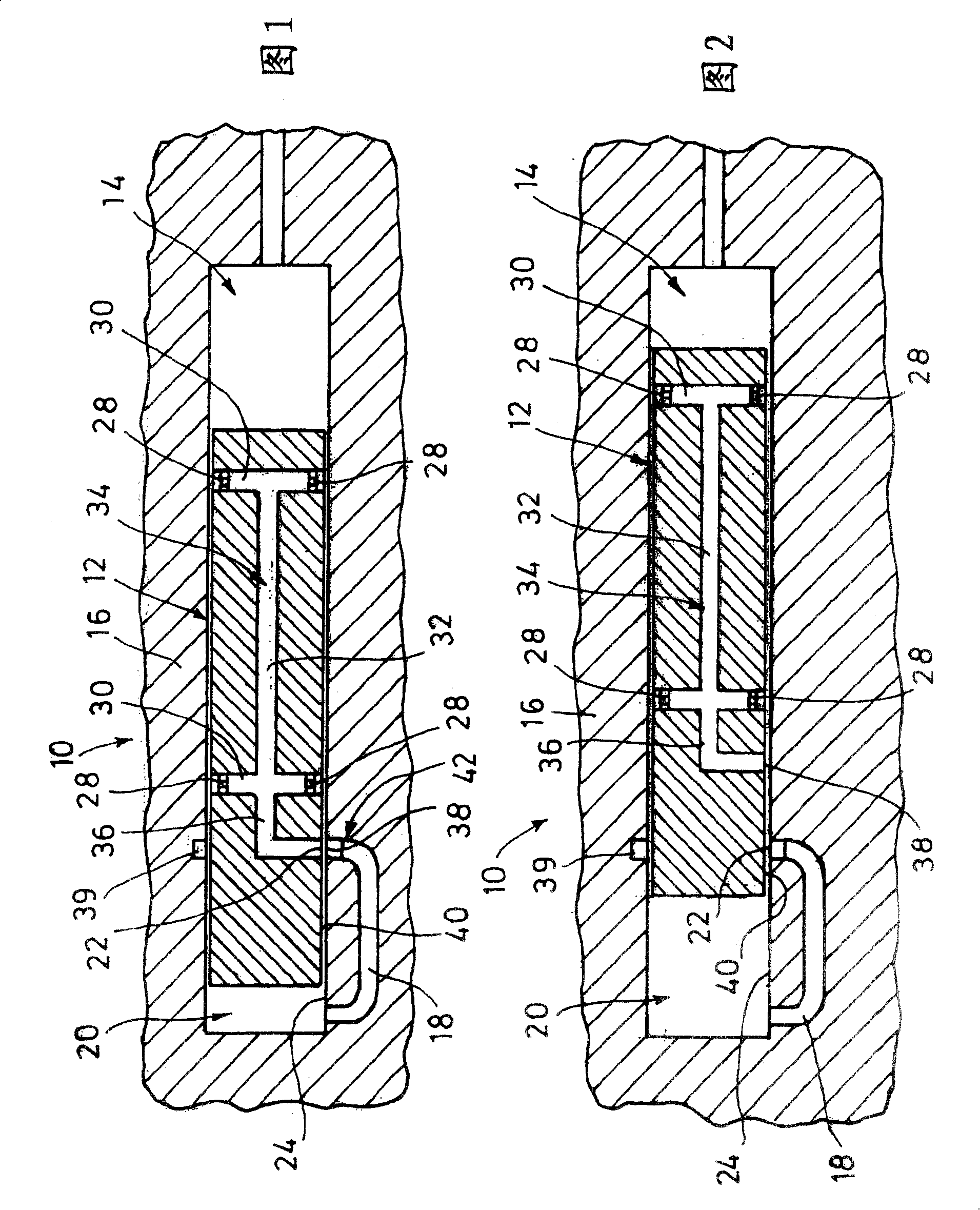

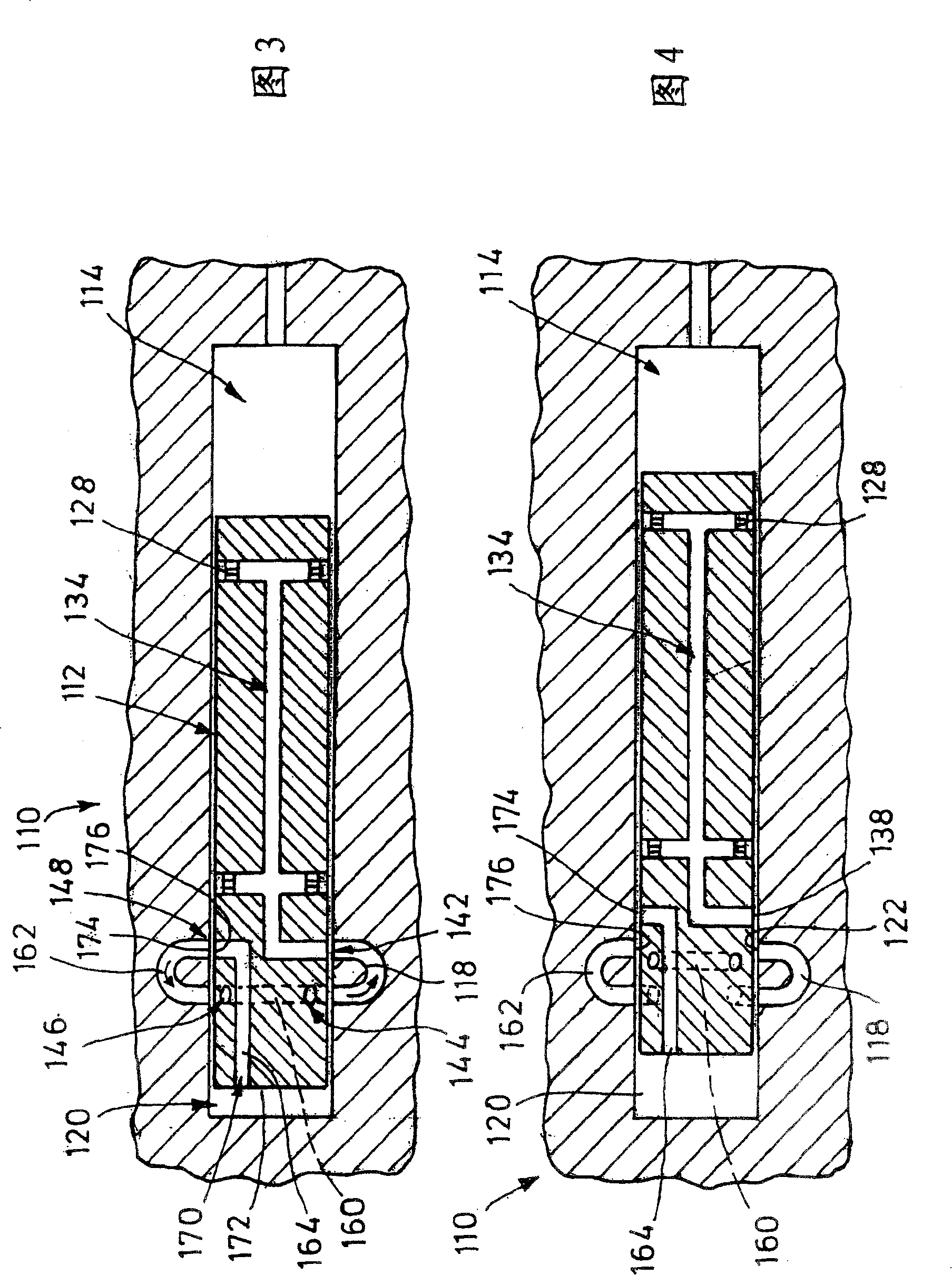

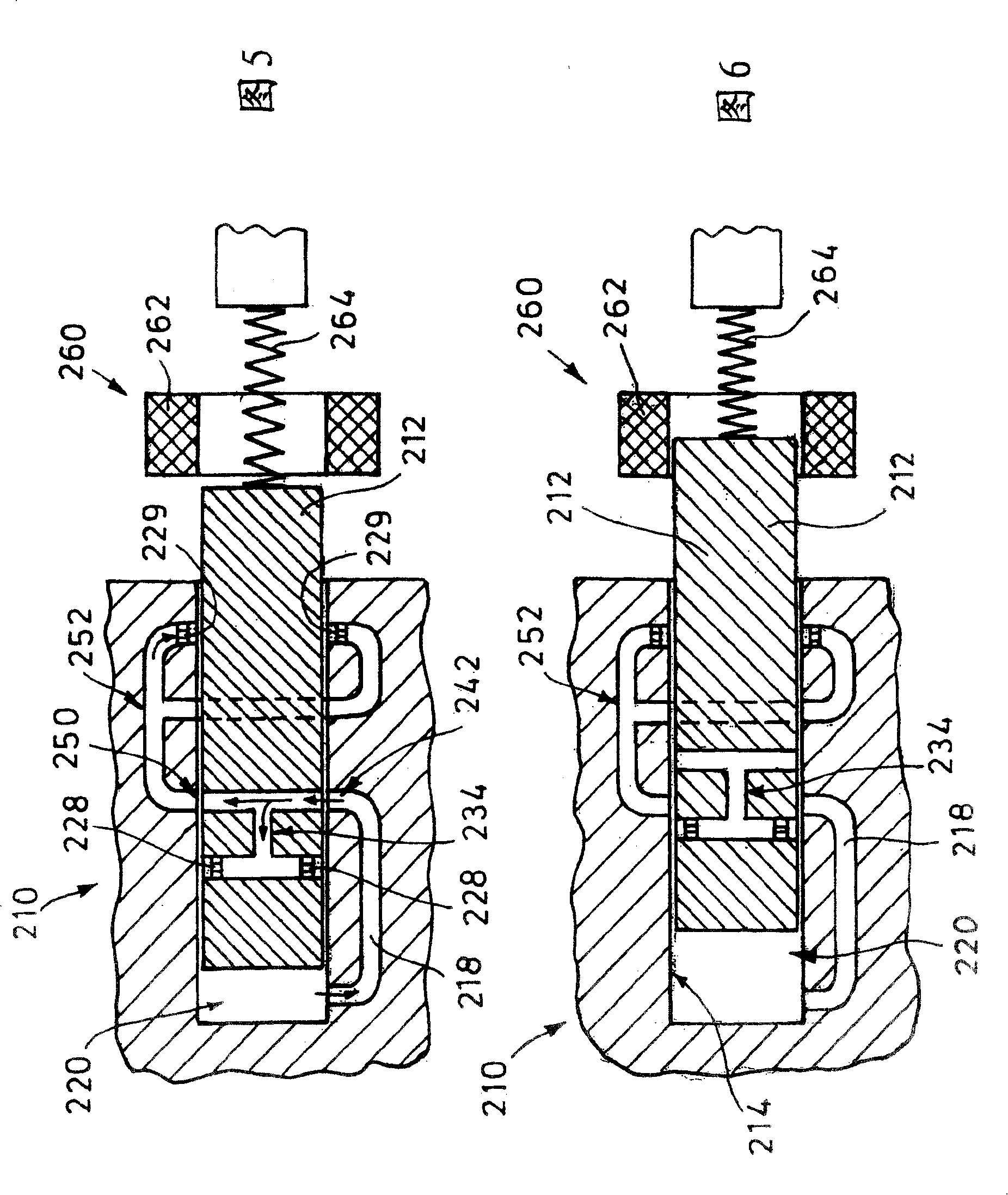

[0028] Figures 1-8 show several embodiments of piston compressors, for example used as components of a Stirling cryocooler. A Stirling cryocooler including a piston compressor is shown in Figure 9.

[0029] A first embodiment of a piston compressor 10 is shown in FIGS. 1 and 2 . Piston compressor 10 basically comprises a piston 12 oscillating within a cylinder 14 between two end positions shown in FIGS. 1 and 2 respectively.

[0030] Inside the shell 16 of the cylinder 14, there is a compressed gas supply line 18 which connects the cylinder compression chamber 20 at one end of the cylinder to a cylinder wall opening 22 in the cylinder side wall 24.

[0031] Piston 12 includes four gas bearing nozzles 28 arranged in two planes, the nozzles being connected to each other by transverse ducts 30 and longitudinal ducts 32 . At least three gas bearing no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com