Bottom valve in density pond

A dense pool and bottom valve technology, which is applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of increased handwheel operation resistance, compaction blocking the discharge port, and fast sedimentation speed, etc., to achieve small operation resistance and simple operation reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

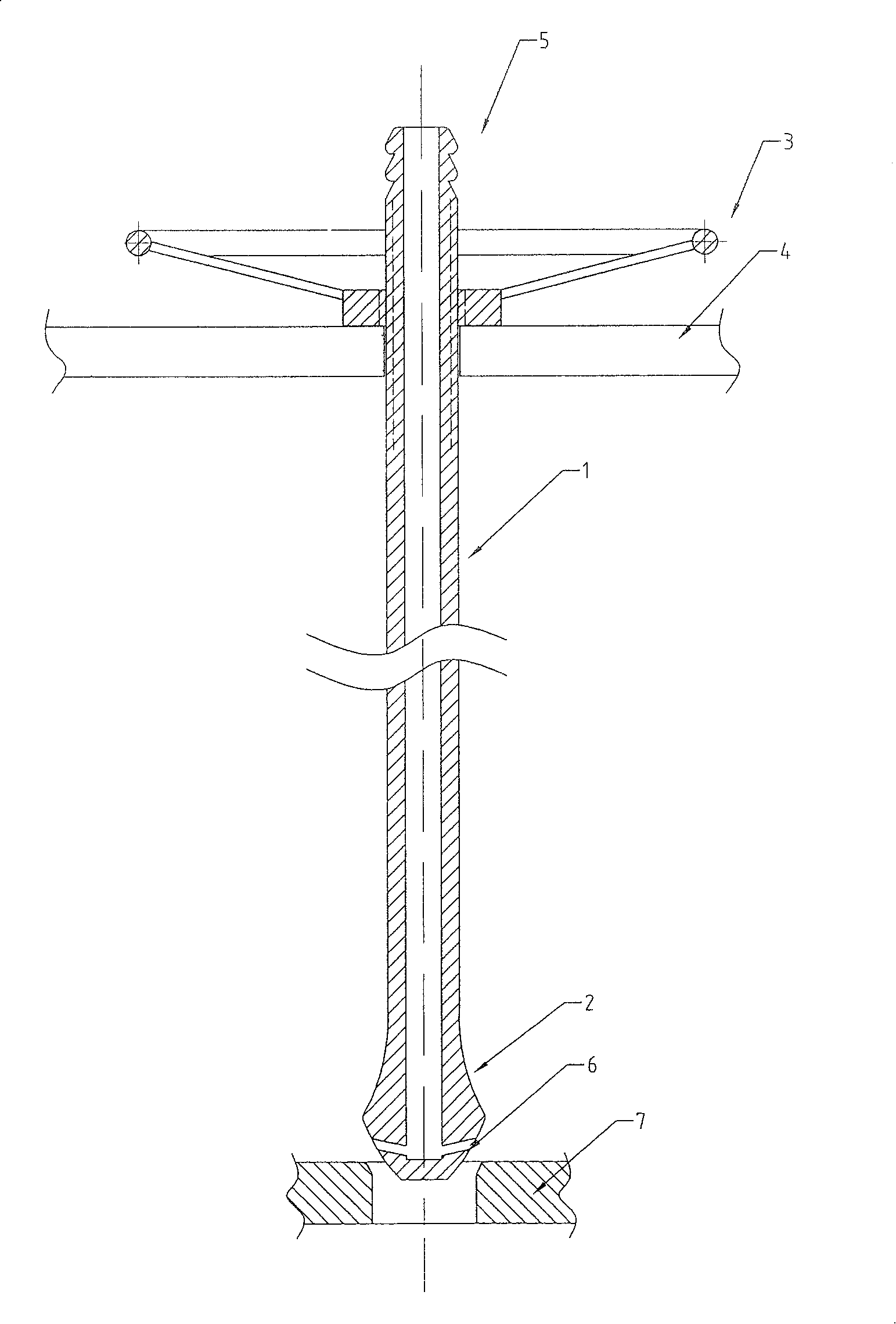

[0013] attached figure 1 Shown is a dense pool bottom valve, which is composed of a valve stem 1, a valve head 2 and a hand wheel 3. The upper end of the valve stem 1 passes through the valve seat 4 and is adjusted up and down by the hand wheel 3 through threads; the valve stem 1 is hollow Tubular structure, the top of the upper end is processed into a nozzle interface 5, and the lower end is connected with a hollow hammer-shaped valve head 2. The valve head 2 is directly above the valve base 7, and the valve base 7 is installed on the discharge port of the dense pool. There are four spray holes radiating in the horizontal direction around a section of the side of the culet.

Embodiment 2

[0015] This embodiment is a dense pool bottom valve, which is composed of a valve stem 1, a valve head 2 and a hand wheel 3. The upper end of the valve stem 1 passes through the valve seat 4 and is adjusted up and down by the hand wheel 3 through threads; the valve stem 1 is hollow. Tubular structure, the top of the upper end is processed into a nozzle interface 5, and the lower end is connected with a hollow hammer-shaped valve head 2. The valve head 2 is directly above the valve base 7, and the valve base 7 is installed on the discharge port of the dense pool. There are eight spray holes radiating toward the horizontal obliquely upward direction around a side of the bottom tip.

Embodiment 3

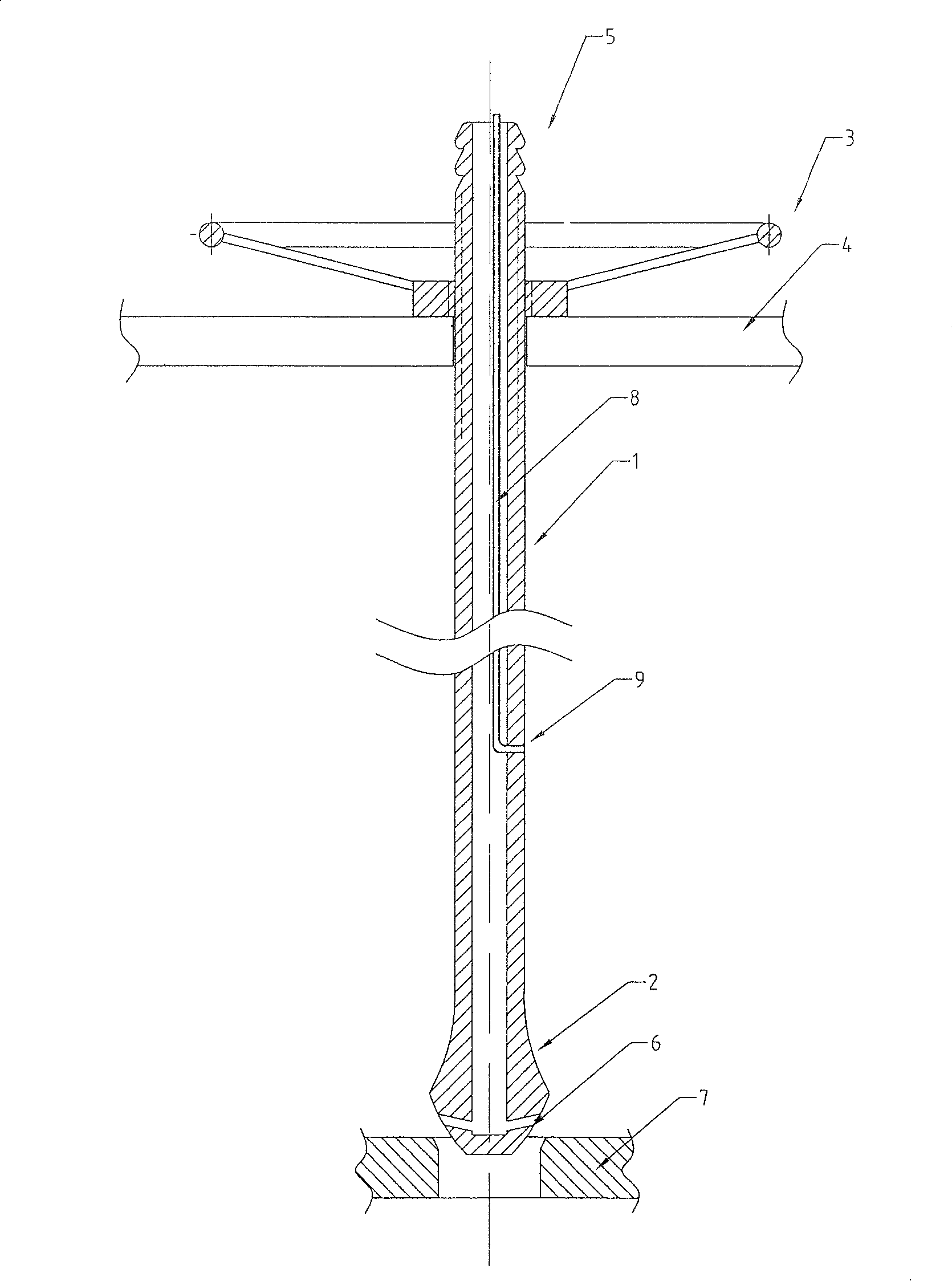

[0017] attached figure 2 Shown is a dense pool bottom valve, which is composed of a valve stem 1, a valve head 2 and a hand wheel 3. The upper end of the valve stem 1 passes through the valve seat 4 and is adjusted up and down by the hand wheel 3 through threads; the valve stem 1 is hollow Tubular structure, the top of the upper end is processed into a nozzle interface 5, and the lower end is connected with a hollow hammer-shaped valve head 2. The valve head 2 is directly above the valve base 7, and the valve base 7 is installed on the discharge port of the dense pool. There are ten spray holes radiating towards the horizontal and the horizontal obliquely upwards on a section of the side of the base. A small-diameter seamless steel pipe 8 is welded in the valve stem 1, and the lower end of the small-diameter seamless steel pipe 8 is connected to the injection hole 9 around the pipe wall of the valve stem.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com