Grinding device for processing composite modified bentonite

A compound modification and grinding device technology, which is applied in the field of bentonite processing, can solve problems such as poor grinding effect, agglomeration, and impure collection, and achieve the effects of avoiding agglomeration, improving grinding quality, and improving grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

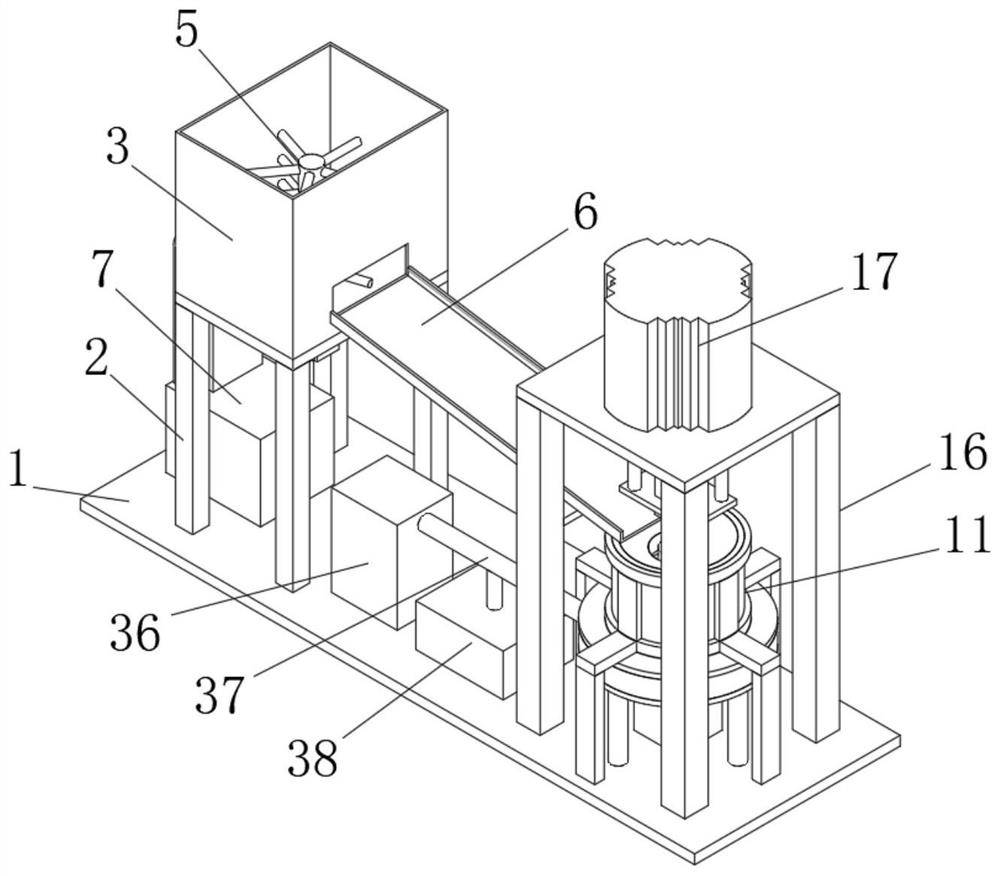

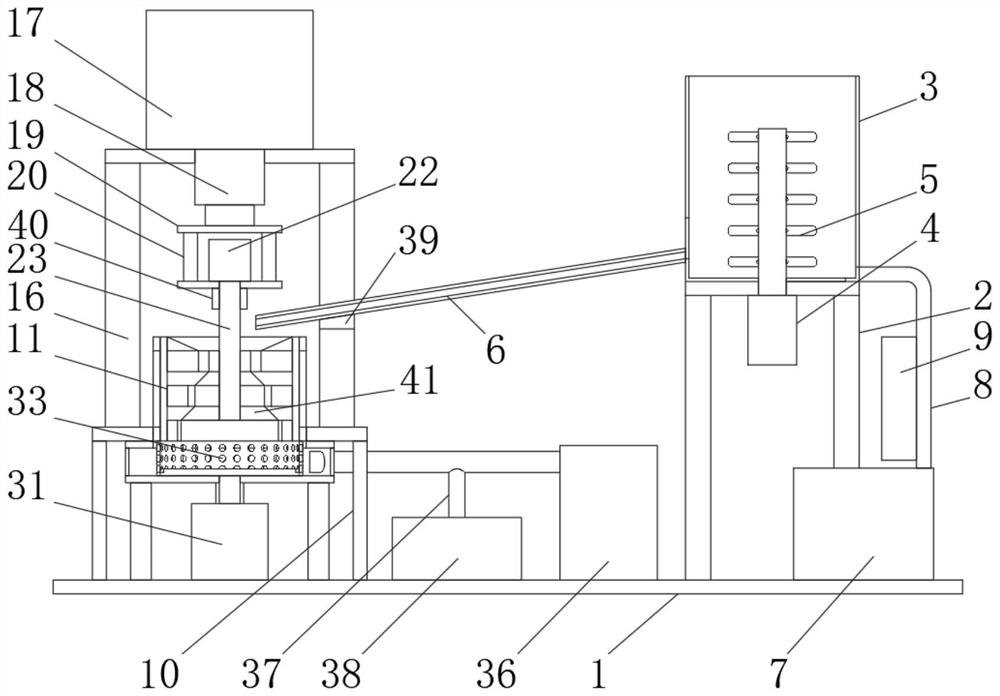

[0029] see Figure 1-8 , the present invention provides a technical solution:

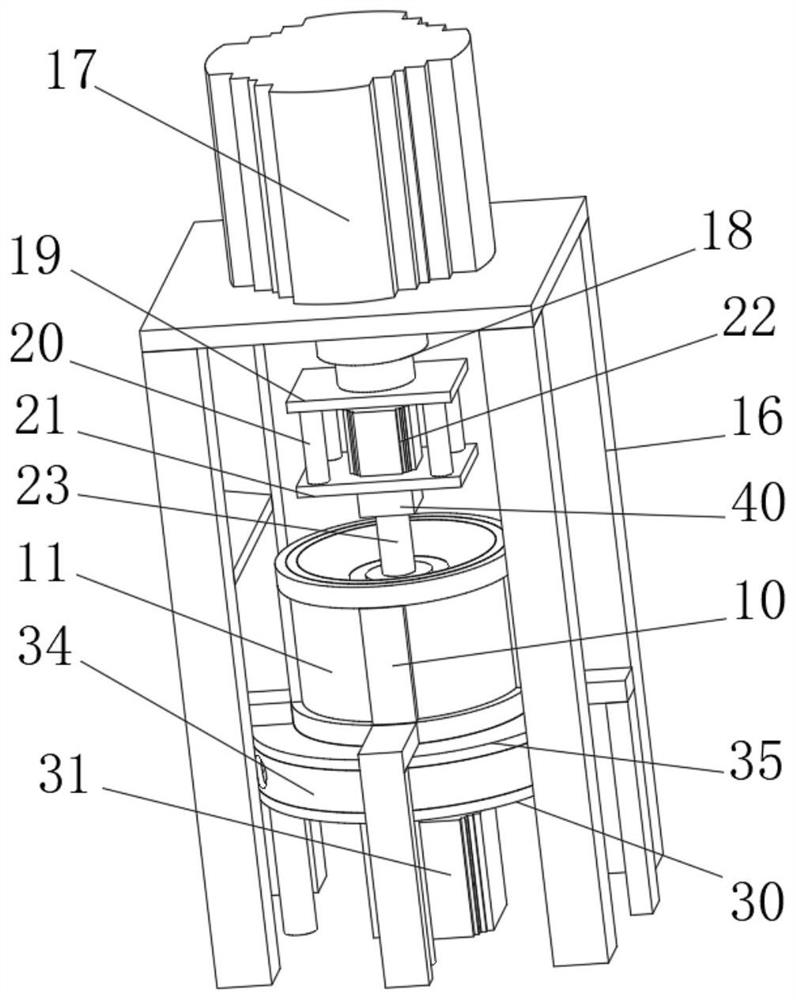

[0030] A grinding device for compound modified bentonite processing, comprising a base 1, a feeding box mounting frame 2, a driving mechanism 17, a third motor 31 and a second blower 36, the surface of the base 1 is fixedly connected with a grinding equipment mounting frame 16 , the drive mechanism 17 is installed through the grinding equipment installation frame 16, so that the drive mechanism 17 is installed above the grinding barrel body 11, the top end of the grinding equipment installation frame 16 is fixedly connected with the drive mechanism 17, and the inside of the drive mechanism 17 is equipped with a telescopic rod 18 One end of the telescopic rod 18 is fixedly connected with a connecting plate 19, and the driving mechanism 17 drives the telescopic rod 18 and connects the connecting plate 19 to slide up and down. The surface of the connecting plate 19 is fixedly connected with four groups ...

Embodiment 2

[0032] On the basis of Embodiment 1, the present invention provides a technical solution:

[0033] A grinding device for compound modified bentonite processing, comprising a base 1, a feeding box installation frame 2, a drive mechanism 17, a third motor 31 and a second blower 36, the inner grinding mechanism 41 is installed inside the outer grinding mechanism 42, the upper layer The inner grinding disc 24, the inner grinding disc 26 of the middle layer and the radius of the inner grinding disc 28 of the next time become equal differences and expand, and the insides of the upper outer grinding disc 14, the outer grinding disc 13 of the middle layer and the grinding barrel body 11 are all provided with perforated and perforated holes. The radius expands into equal difference, the inner grinding disc 24 of the upper layer is positioned at the opening circle center position of the upper outer grinding disc 14, the inner grinding disc 26 of the middle layer is positioned at the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com