A method for increasing production of oil and gas wells using hydration reaction hydrogen-releasing components

A technology for applying hydration and oil and gas wells, applied in the field of oil and gas well stimulation, can solve problems such as insufficient utilization of hydrogen efficiency, and achieve the effect of increasing the duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

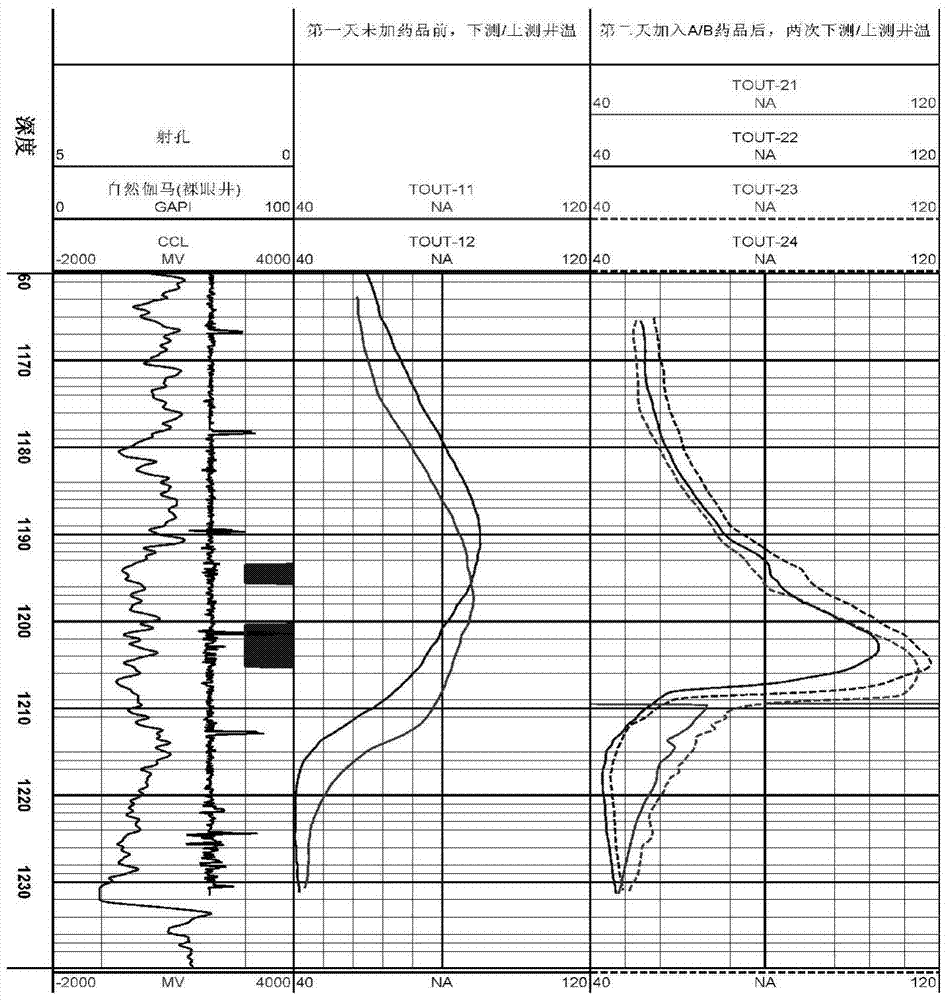

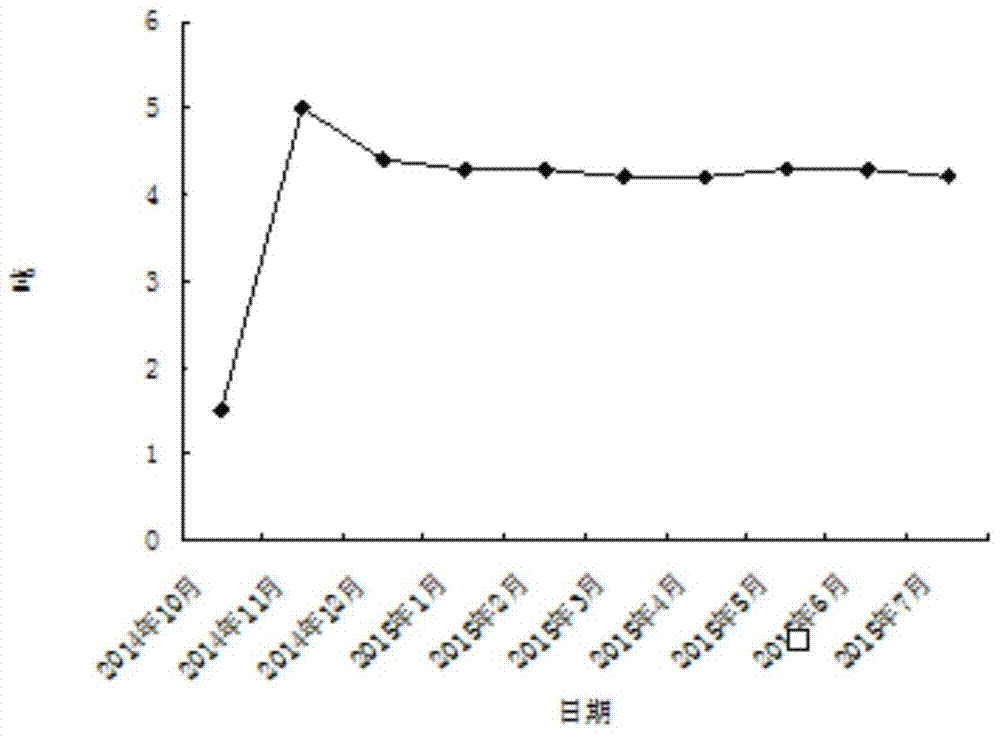

[0061] Example 1: Hydrogenation hot gas chemical stimulation operation of Pai-684 oil well in Keshengli Oilfield, Xinjiang

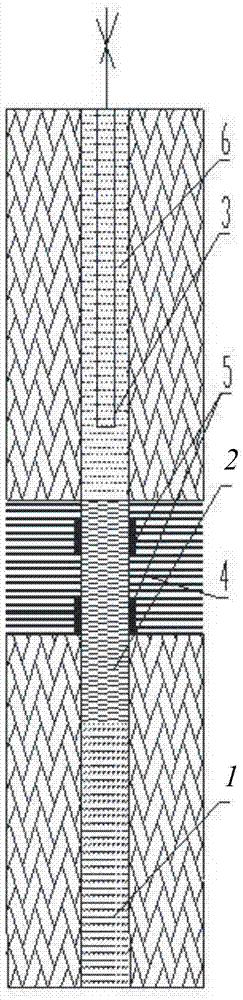

[0062] Geological conditions and related parameters of Pai-684 oil well: reservoir series sandstone and siltstone; low permeability oil layer; casing diameter ( figure 1 diameter of the oil well) Well depth (distance from surface to well bottom) 1239.4m; artificial well bottom 1239.4m; perforation range 1194-1205m; tubing diameter Before the production increase operation, the daily liquid production was 2.4t, of which the daily oil production was 1.5t;

[0063] From the above data, it can be concluded that the volume of the reaction zone is 688 liters, 379.6 liters of No. 1 solution and 308.4 liters of No. 2 solution are prepared.

[0064] No. 1 solution 493.5kg, that is, No. 1 solution is composed of 281.3kg of ammonium nitrate NH 4 NO 3 , 83.9kg of urea CO(NH 2 ) 2 , 69.1kg of nitric acid HNO 3 and 59.2kg of H 2 O composition.

[0065] No. 2...

Embodiment 2

[0079] Example 2: Hydrogenation hot gas chemical stimulation operation of Liang-113 oil well in Chunliang area, Shandong

[0080] Geological conditions and related parameters of Liang-113 oil well: the reservoir is sandstone and mudstone; it belongs to ultra-low permeability and ultra-heavy oil layer; casing diameter Well depth 2858.7m; artificial well bottom 2858.7m; perforation range 2765-2769m; tubing diameter Before the stimulation operation, the daily liquid production was 3.7t, of which the daily oil production was 2.6t; from the above data, it can be concluded that the volume of the reaction zone is 1420.2 liters. Prepare 783.6 liters of No. 1 solution and 636.6 liters of No. 2 solution.

[0081] That is, 1018.6kg of No. 1 solution, calculated by mass percentage, is composed of 607.8kg of ammonium nitrate NH 4 NO 3 , 176.6kg of urea CO (NH 2 ) 2 , 95.5kg of nitric acid HNO 3 and 138.7kg of H 2 O composition.

[0082] No. 2 solution 1018.6.kg, calculated by mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com