Control device for compressor

A control device and compressor technology, which is applied in the field of compressor control devices, can solve the problems of general products without structure, achieve the effects of simplification of loop circuit composition, wide use value, and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation, structure, features and functions of the compressor control device according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

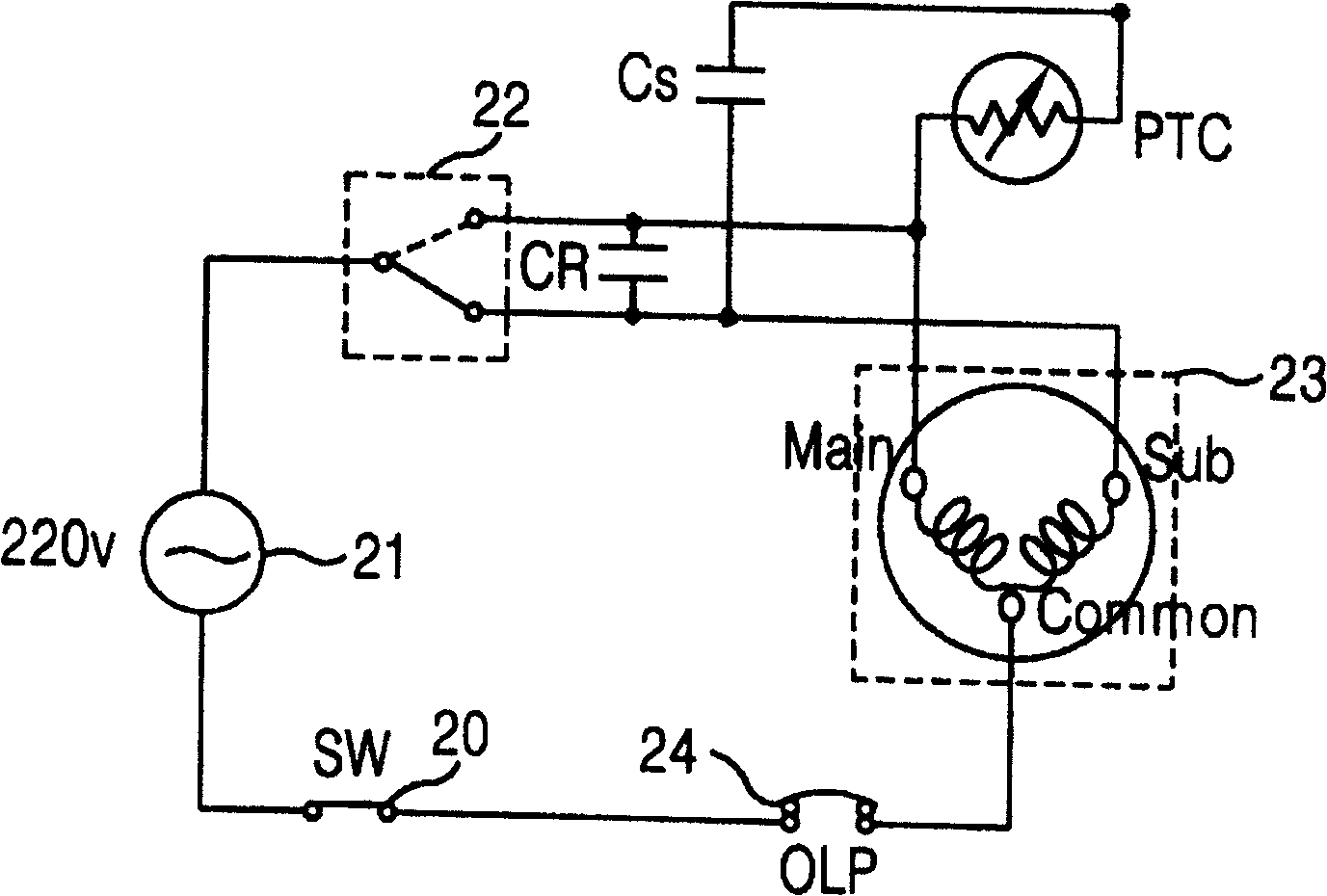

[0036] see image 3Shown is the schematic circuit diagram of the control device of the compressor of the present invention. As shown in the figure, the control device of the compressor in the preferred embodiment of the present invention includes: a power supply part 21 that outputs a certain voltage to the motor when the main switch 20 is turned on; Then select the relay 22 that supplies a certain voltage, and when starting the motor, make the phase of the current supplied by the above-mentioned relay 22 accelerate and then output the starting capacitor CS, and when starting and running the motor after starting, the phase of the current supplied by the above-mentioned relay 22 is accelerated. After that, the running capacitor CR, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com