Leakproof pattern plate

A formwork and leak-proof technology, applied in the field preparation of formwork/formwork components and building components, construction, etc., can solve the problem of single, can not solve the leak-proof problem, etc., achieve low cost, prolong the leakage path, improve the construction holistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Figure 25 Shown is a schematic diagram of the structure of the existing formwork. The common formwork 101 is strip-shaped, and its front is a single plane, which is used for the parts connected with the surfaces of the main bodies of the concrete columns. Can also be used when pouring quarter corners. The other is the external corner special-shaped formwork 102, which is mainly used for pouring convex right-angle corner parts. On the other hand, there is also a special-shaped formwork 103 for female corners, which is mainly used for pouring concave right-angle corners. There is also a curved formwork, which is mainly used for casting curved corners. The defects of this type of template have been described above, and will not be repeated here.

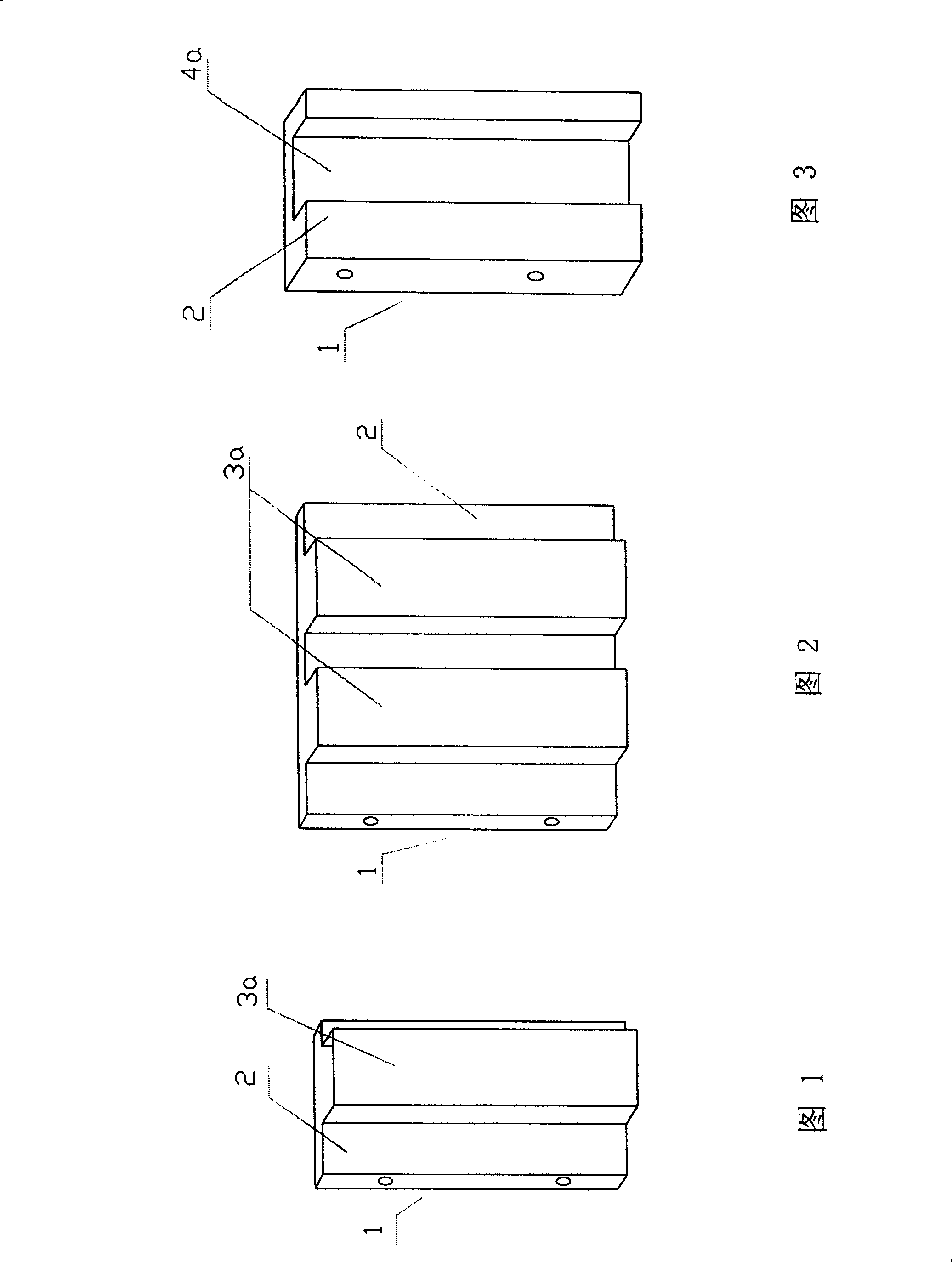

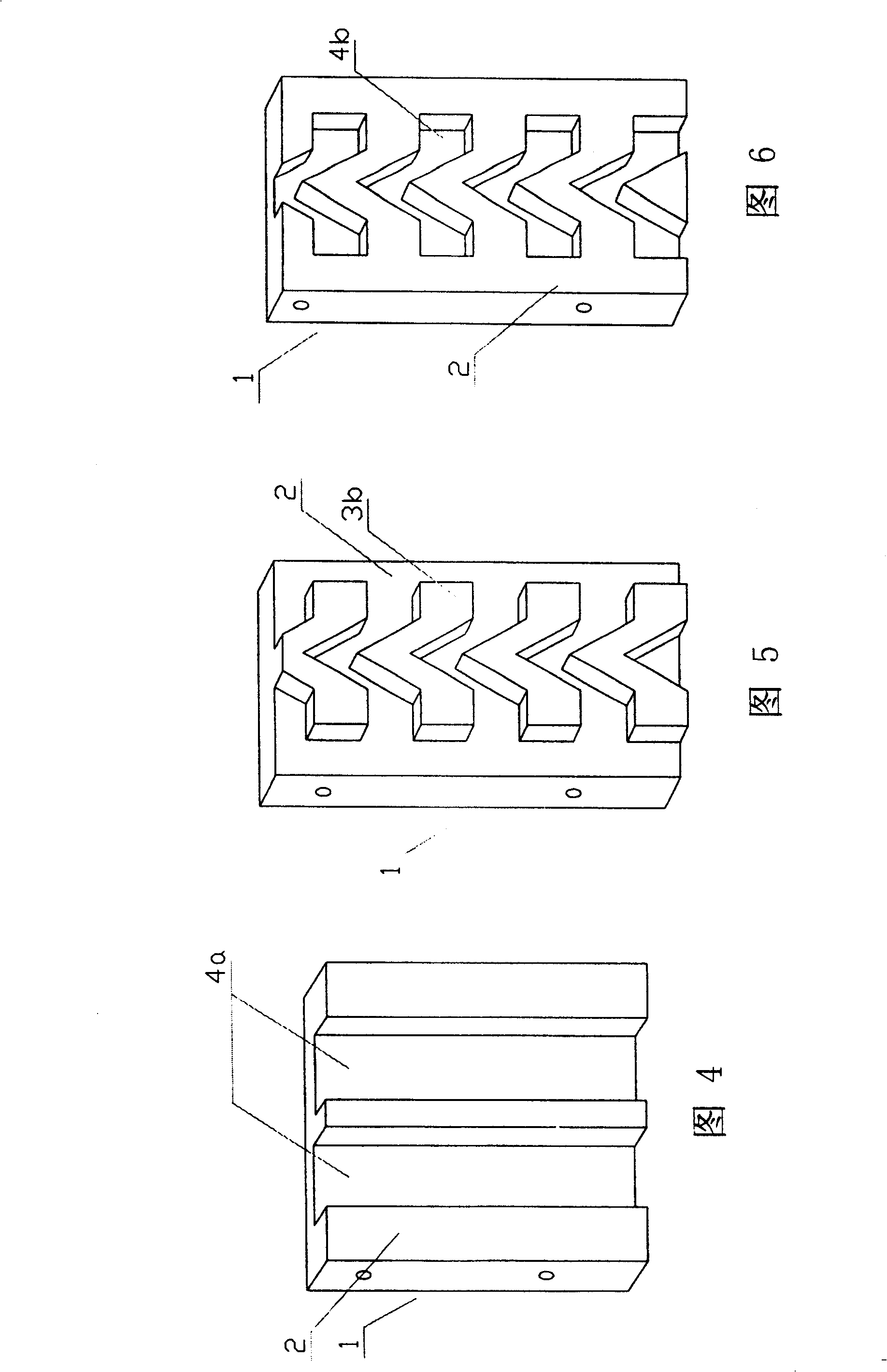

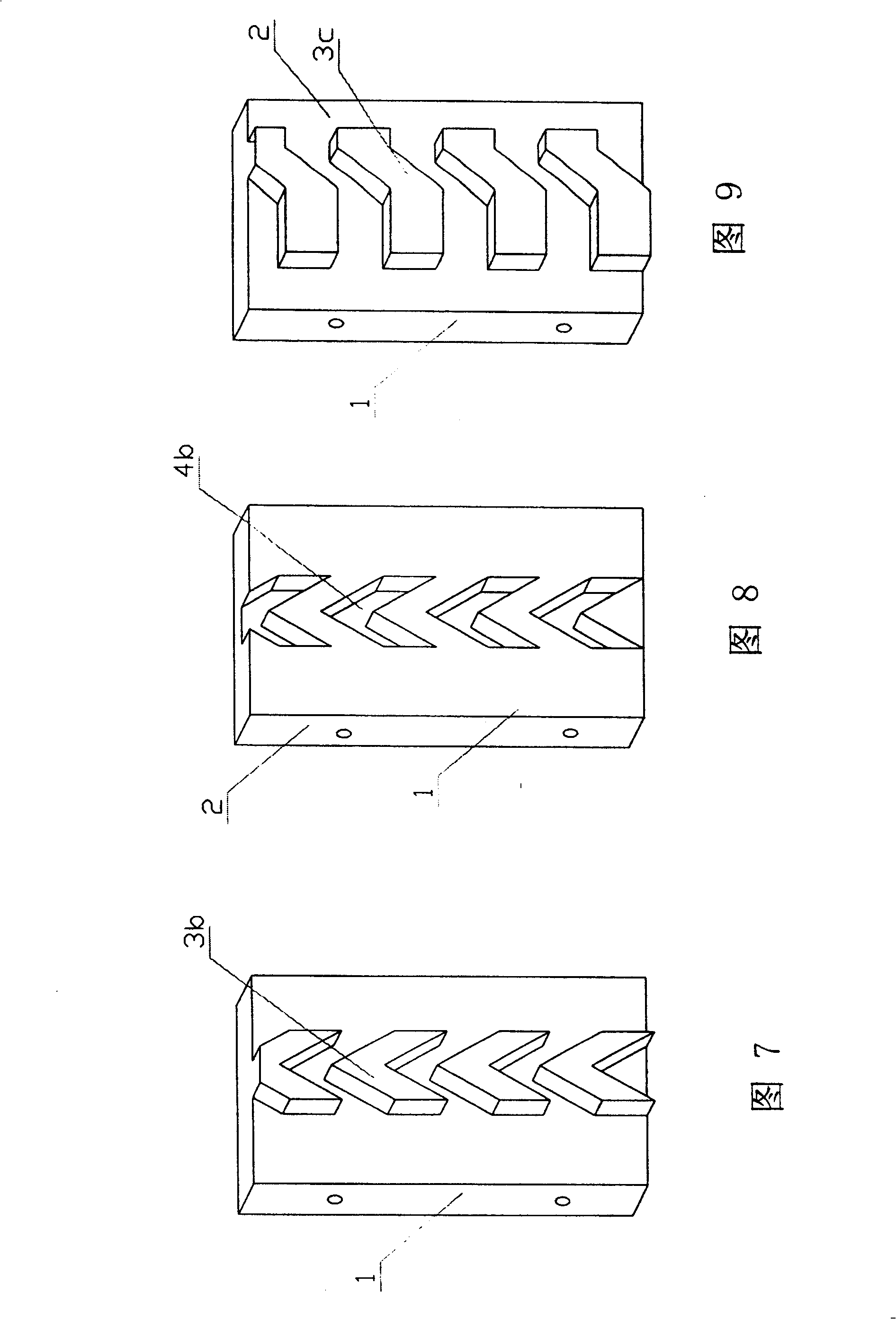

[0036] Referring to Fig. 1 to Fig. 12, the leak-proof formwork of the present invention has ribs or grooves matching the shape of the block on the front side 2 of the body 1 . The rib is a single rib 3a running through the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com