A method for preventing and controlling cracks in masonry walls of strong vibration ramps

A masonry wall and ramp technology, applied in construction, building maintenance, building construction, etc., can solve the problems of poor wall structure stability, high traffic frequency, increased cost, etc., to improve integrity, improve structural strength, Avoid the effect of increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

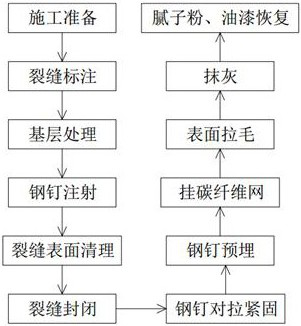

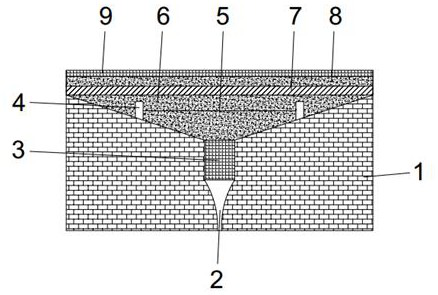

[0027] Refer to attached Figure 1~2 , a kind of strong vibration ramp masonry wall crack prevention method of the present invention, this prevention method comprises the steps:

[0028] (1) Construction preparation: use colored strips and waste templates to spread on the ground to prevent the ground from being damaged by beating mortar blocks;

[0029] (2) Marking of cracks: Check the length, width, depth, and direction of cracks, and mark the position of crack removal. The range of cracks should be square and straight to facilitate later construction and ensure beautiful construction;

[0030] (3) Base treatment: Cut all plastering surfaces within 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com