Method and device for inputing waste hot water to prevent freezing and using hot for solar water heater in winter

A hot water device and water heater technology, which is applied to solar thermal devices, heating devices, solar thermal power generation, etc., can solve the problems of use, the water tank is frozen, and can only be increased by about a few degrees, and achieves huge economic and social benefits. Simple, the effect of promoting great development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present invention will be described in detail below in conjunction with the drawings:

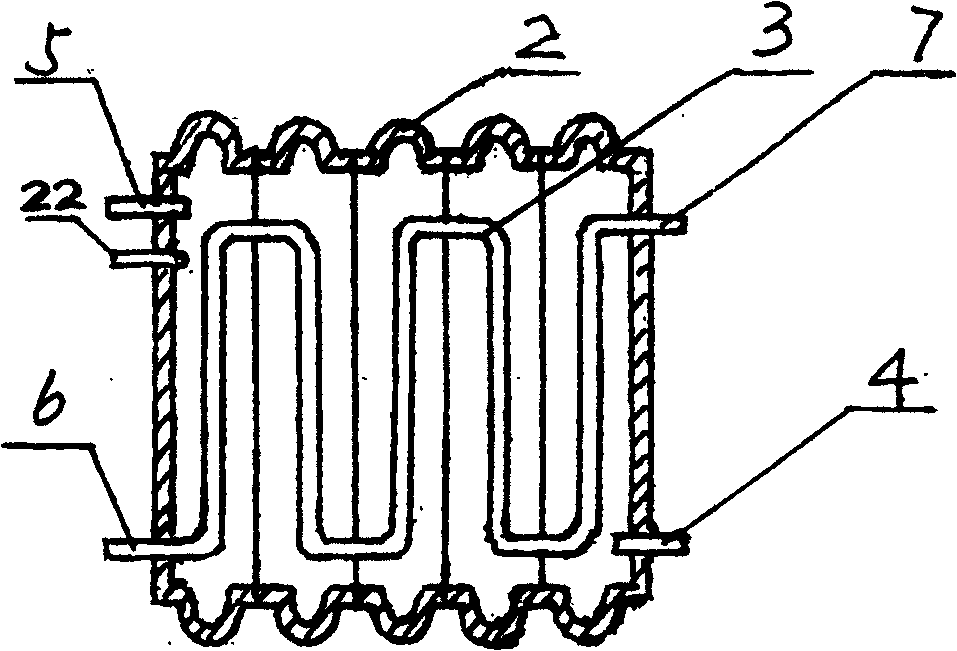

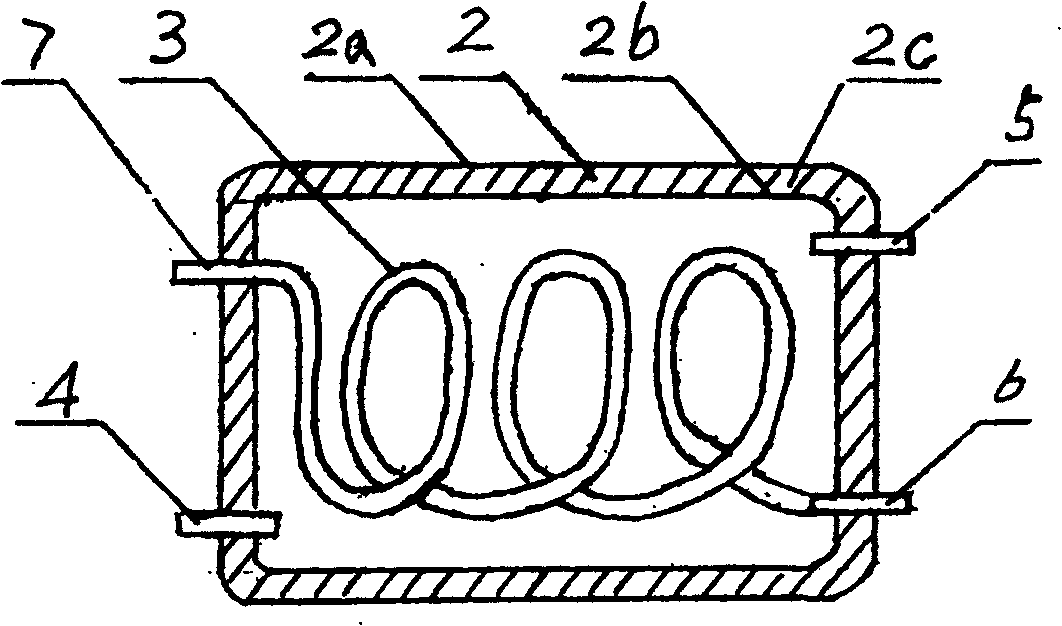

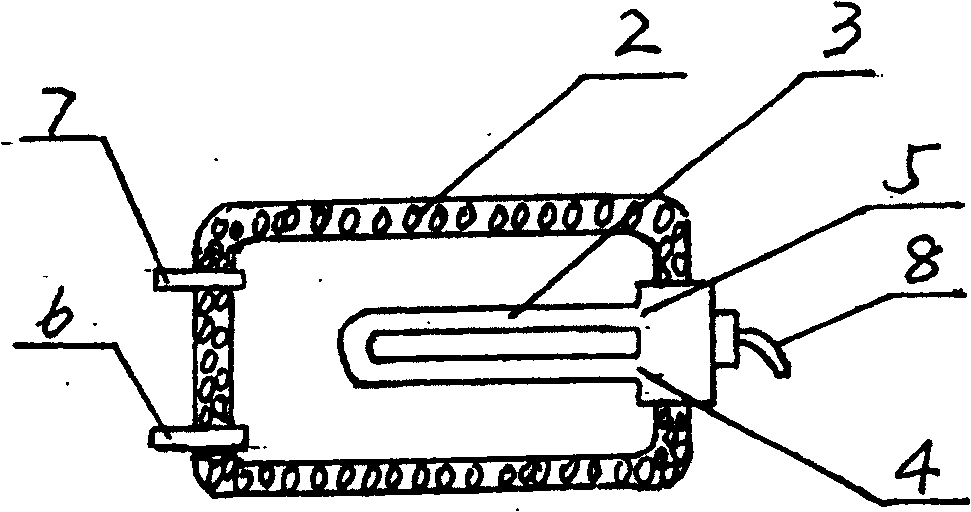

[0036] in figure 1 In the solar water heater, the winter input residual hot water antifreeze and hot water use device (ie, the waste heat device 1) is a radiator split combined type, and its device is composed of a shell 2, a preheater 3, and the like. Among them, the shell 2 can be made of cast iron, or cast aluminum, stainless steel, engineering plastics or other materials; its shape can be made of a combination of several radiators, (of course, the shell 2 can also be made Whole cavity type). The shell 2 is provided with a waste heat inlet 4, a waste heat outlet 5, and a waste hot water inlet 6 and a waste hot water outlet 7 respectively. The housing 2 is provided with a preheating body 3. The material of the preheating body 3 can be stainless steel pipes, copper pipes, aluminum-plastic pipes and other materials, and its shape can be made into an integral ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com