Container paint house system with exhaust-gas treatment facilities

A waste gas treatment and container technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of waste and huge investment, achieve good combustion conditions, reduce costs, and improve the effect of waste gas purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

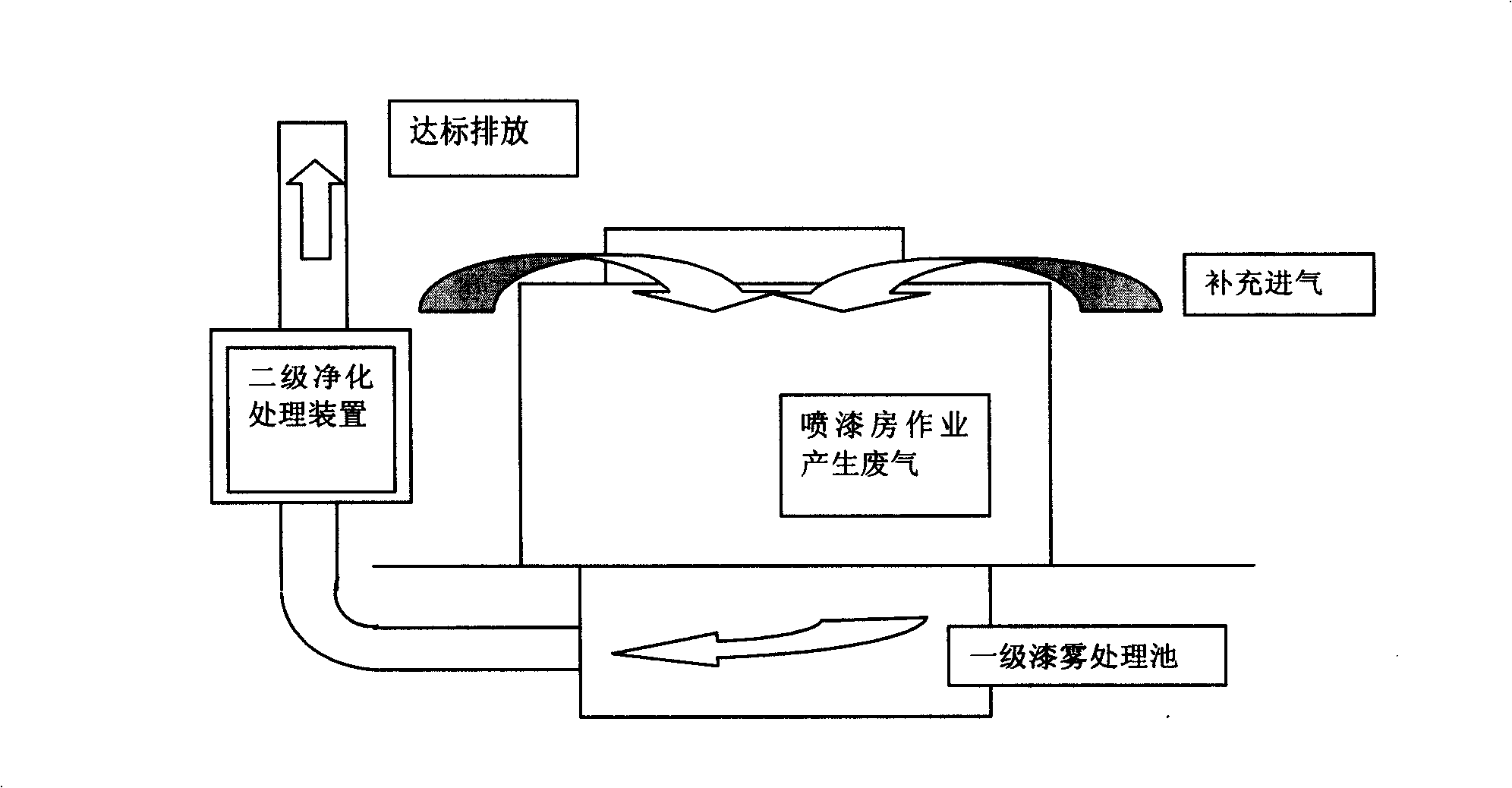

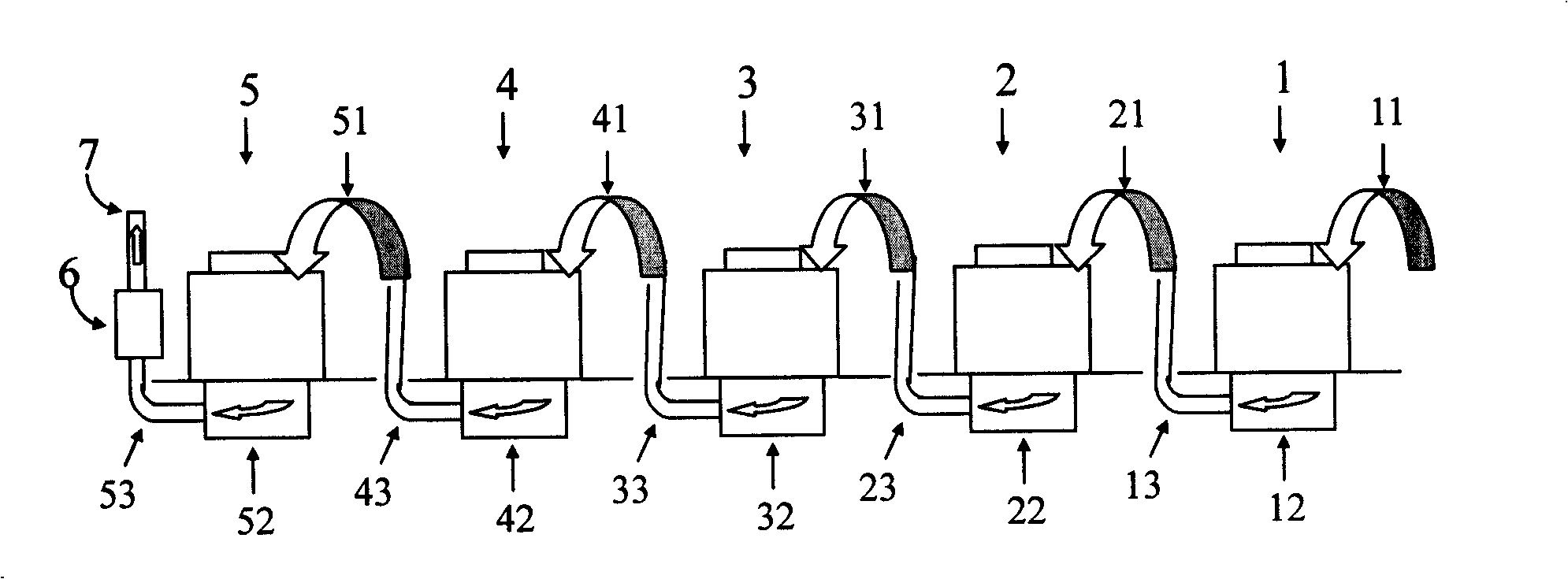

[0015] Specific embodiments of the present invention are as image 3 As shown, a container paint room system with waste gas treatment facilities includes a primer room or a middle paint room or a top paint room 1 and a repair OK room 2 related to the primer room or the middle paint room or the top paint room 1, Leveling room 3, pre-coating room 4 and drying room 5. Among them, there are waste gas treatment facilities in each of the paint rooms, and each waste gas treatment facility includes air intake pipes, primary paint mist treatment pools and exhaust pipes, primer booths or middle paint booths or topcoat The exhaust pipe 13 of the waste gas treatment facility in room 1 is connected with the air intake pipe 21 of the repaired OK room, the exhaust pipe 23 of the repaired OK room 2 is connected with the air intake pipe 31 of the leveling room 3, and the exhaust of the leveling room 3 Pipeline 33 is communicated with the intake duct 41 of pre-coating room 4, the exhaust duct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com