Connection structure adjecent front verticlal pole of vehicle

A technology for connecting structures and uprights, which is applied in the directions of superstructure, superstructure sub-assemblies, vehicle components, etc., to reduce vehicle weight, reduce production costs, and improve driving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

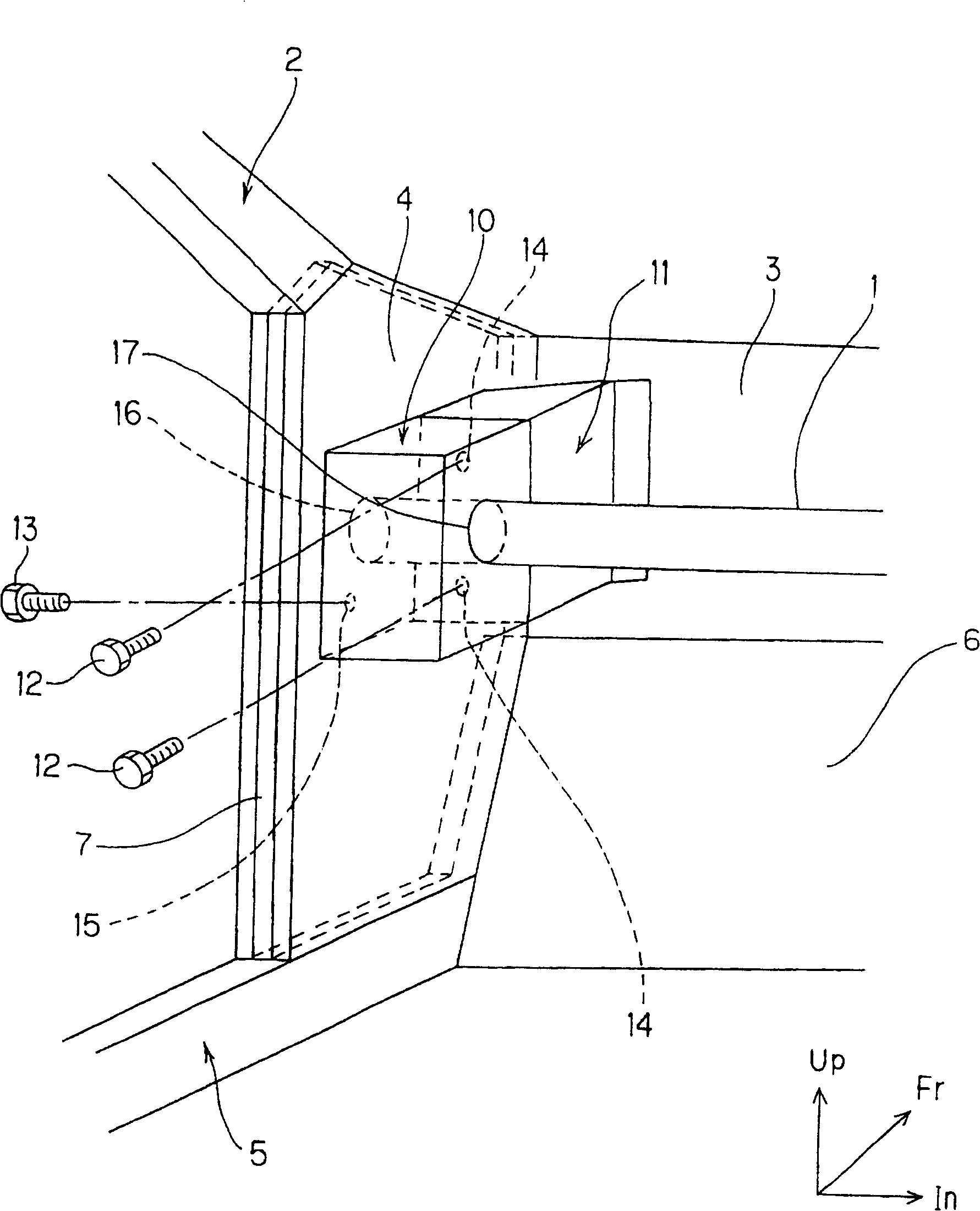

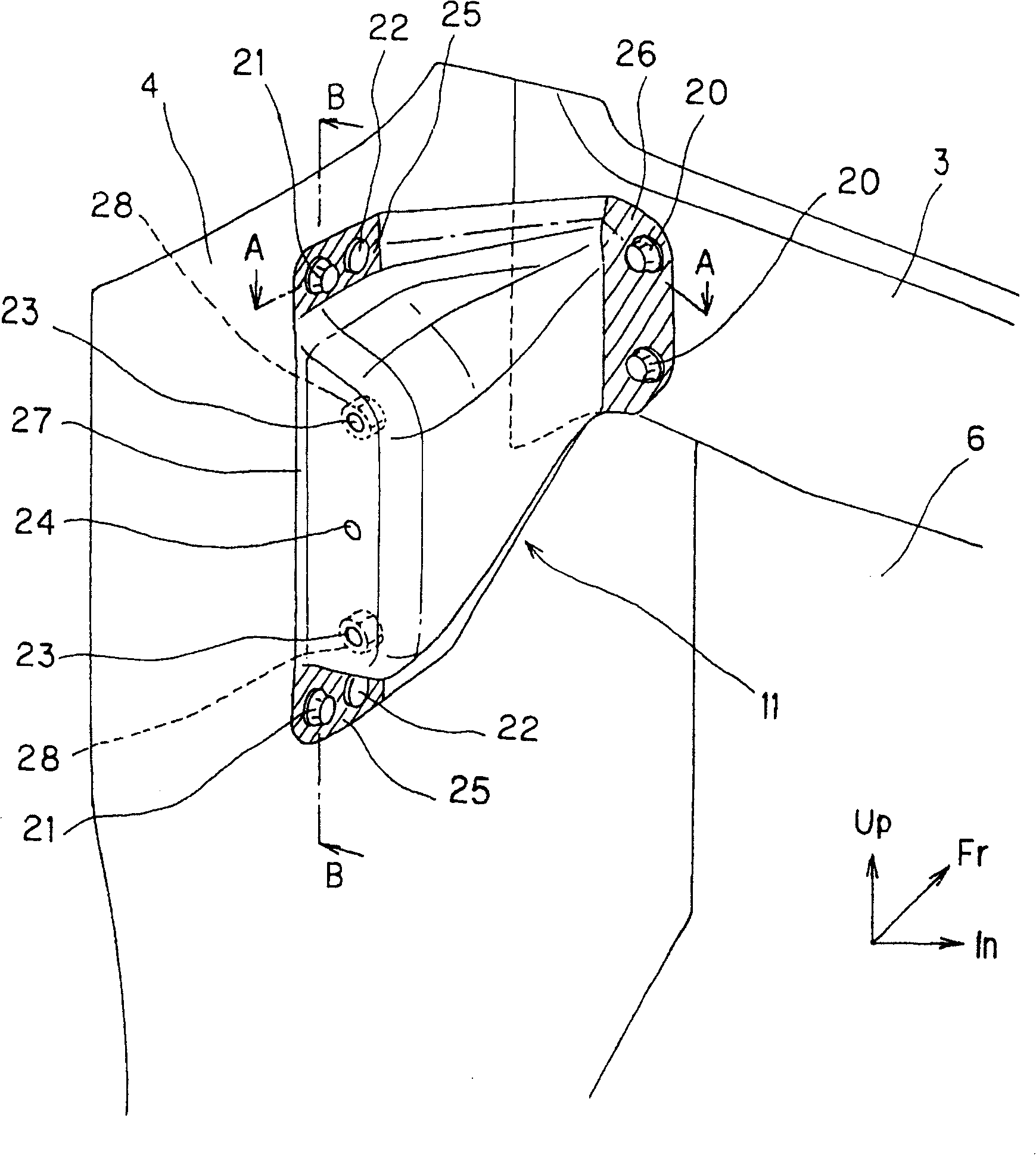

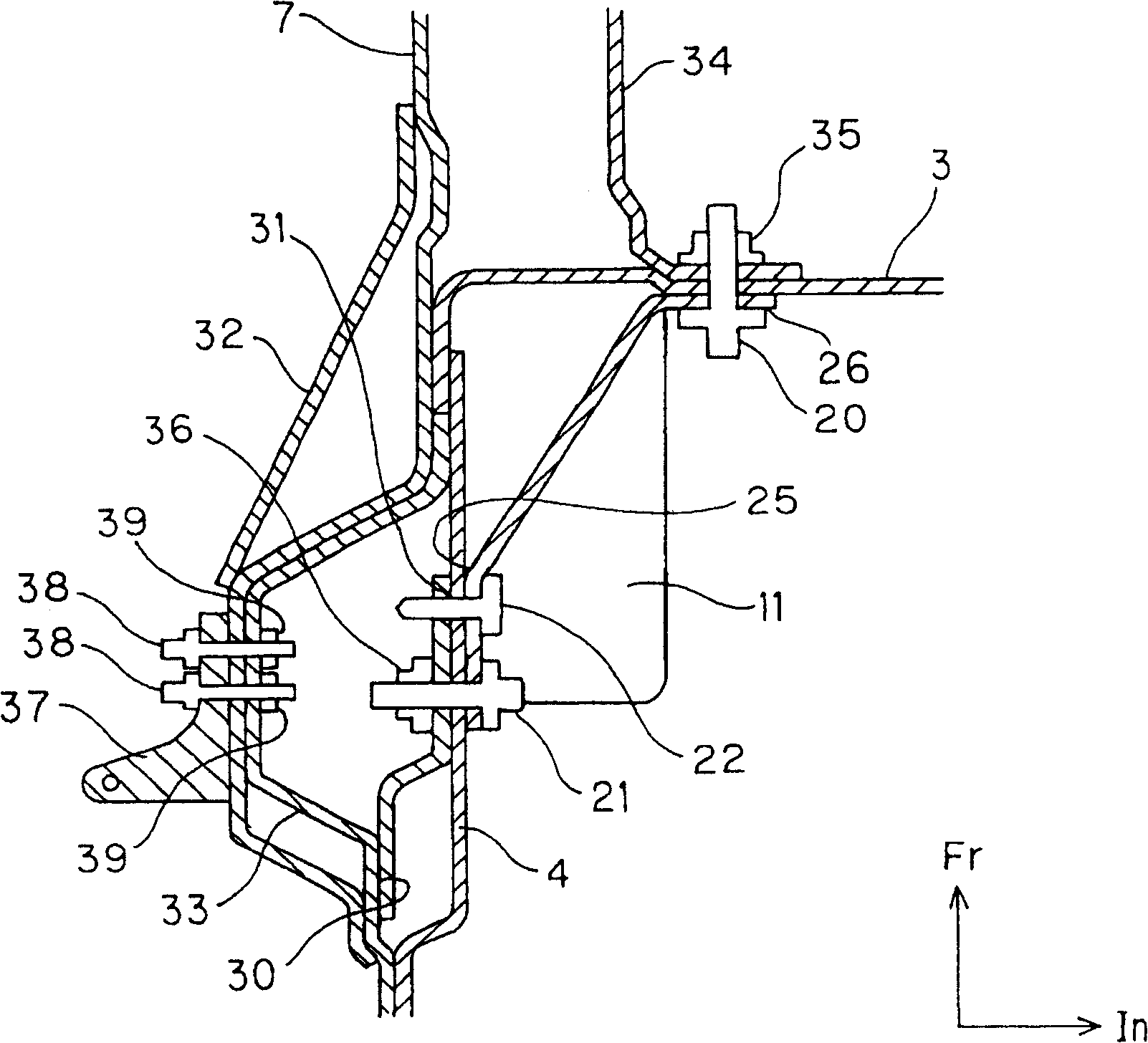

[0033] Below, refer to the attached Figures 1 to 5 One embodiment of the connecting structure near the front pillar of the vehicle body according to the present invention will be described. figure 1 It is a schematic diagram showing the connection structure near the front pillar of the vehicle body according to an embodiment of the present invention, figure 2 To show a perspective view of a support bracket according to an embodiment of the present invention, image 3 A sectional view showing a section A-A of a support bracket according to an embodiment of the present invention, Figure 4 To show a sectional view of a support bracket B-B section according to an embodiment of the present invention, Figure 5 It is a perspective view showing a bracket of a deck beam according to an embodiment of the present invention. In the figure, Fr indicates the vehicle front direction, In indicates the vehicle interior side in the vehicle width direction, and Up indicates the vehicle up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com