Coating tool and coating appts.

A coating and tool technology, applied in the field of coating tools and coating devices, can solve the problems of difficult and precise fine adjustment and long working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

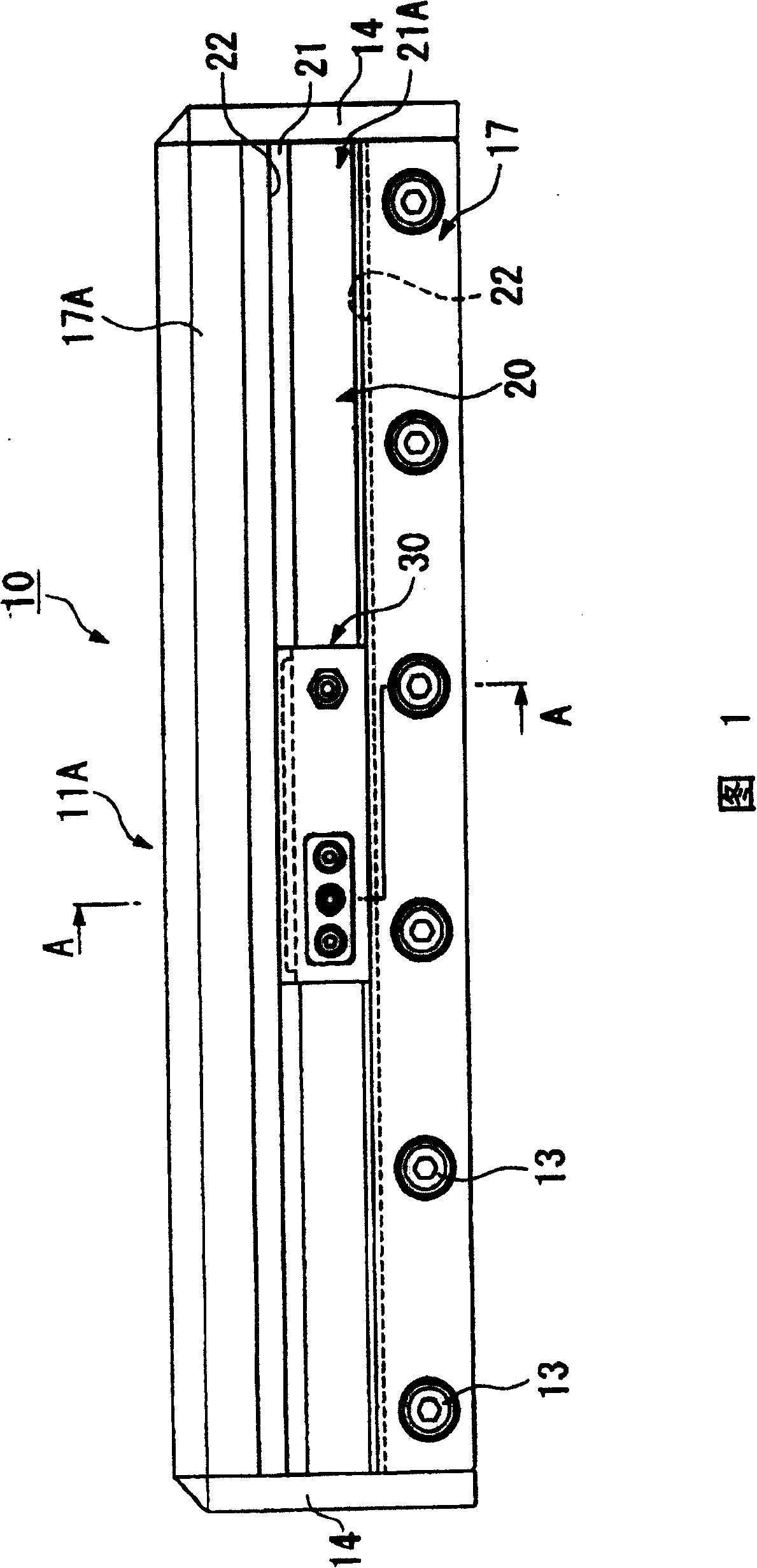

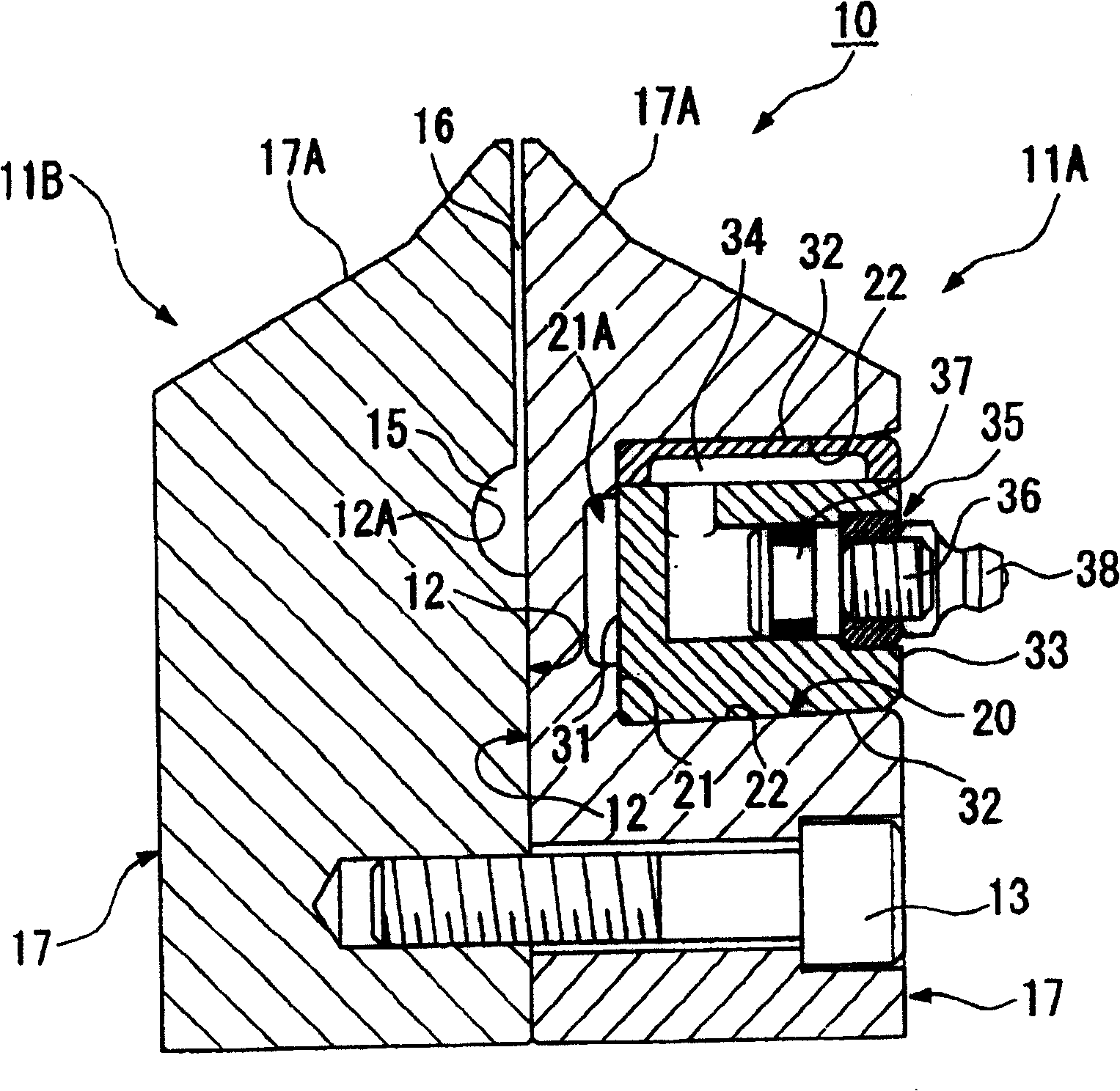

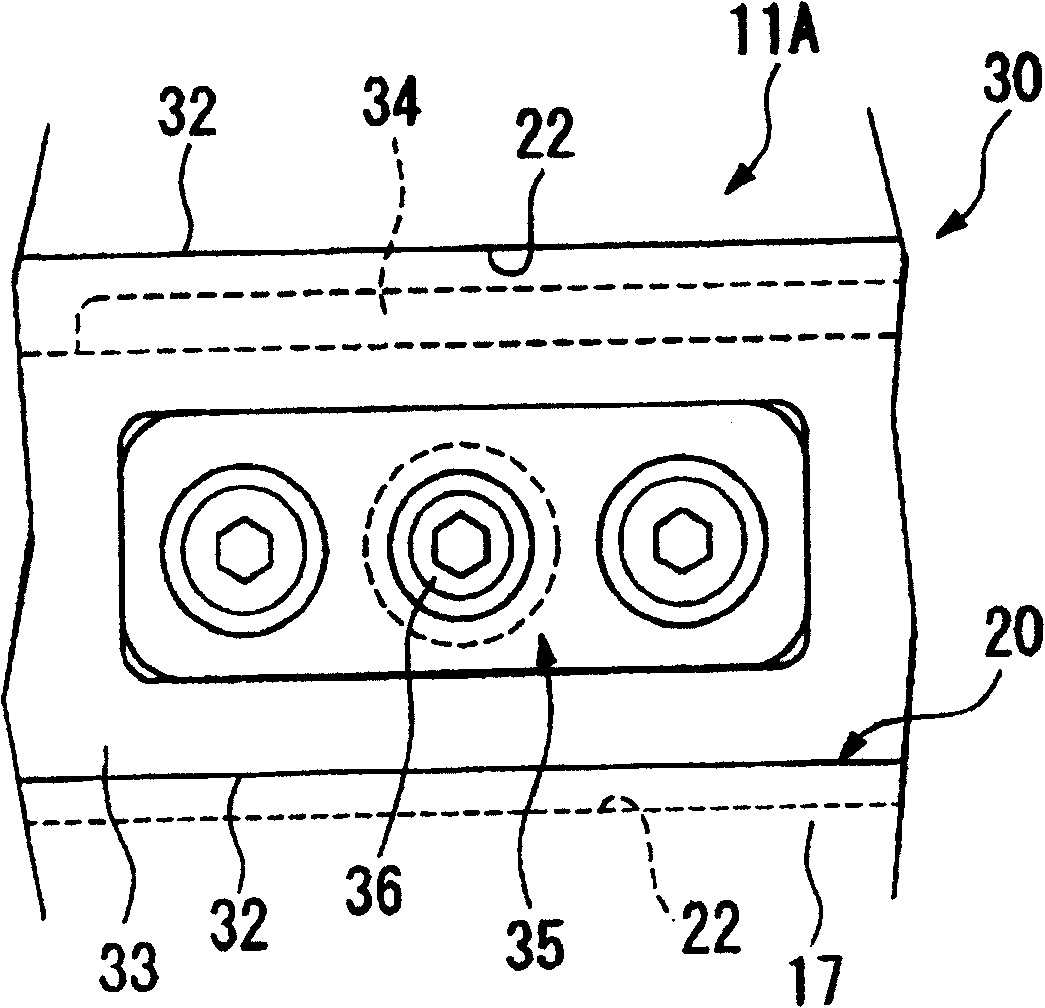

[0027] Figure 1 and figure 2 As shown, the coating head 10 of the coating tool according to the first embodiment of the present invention is composed of a pair of head parts 11A, 11B such that their one side surfaces 12, 12 are opposed to each other, thus forming a vertically long shape. .

[0028] In addition, the pair of head members 11A, 11B constituting the coating head 10 pass through their mutual rear end sides (FIGS. 1 and 10). figure 2 The part on the lower side) is fixed by a plurality of bolts 13 at predetermined intervals in the direction along the length direction of the coating head 10 (the left-right direction in FIG. 1 ), and is positioned relative to the Side plates 14, 14 are attached to the end faces of both ends in the direction of the longitudinal direction, respectively, so as to be fixed to each other.

[0029] One head part 11A ( figure 2 Amon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com