Method for detecting position displacement of cutting blades

A cutting blade and detection method technology, which is applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problem of inability to correctly measure the position deviation of cutting blades, and achieve the goal of preventing miscutting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

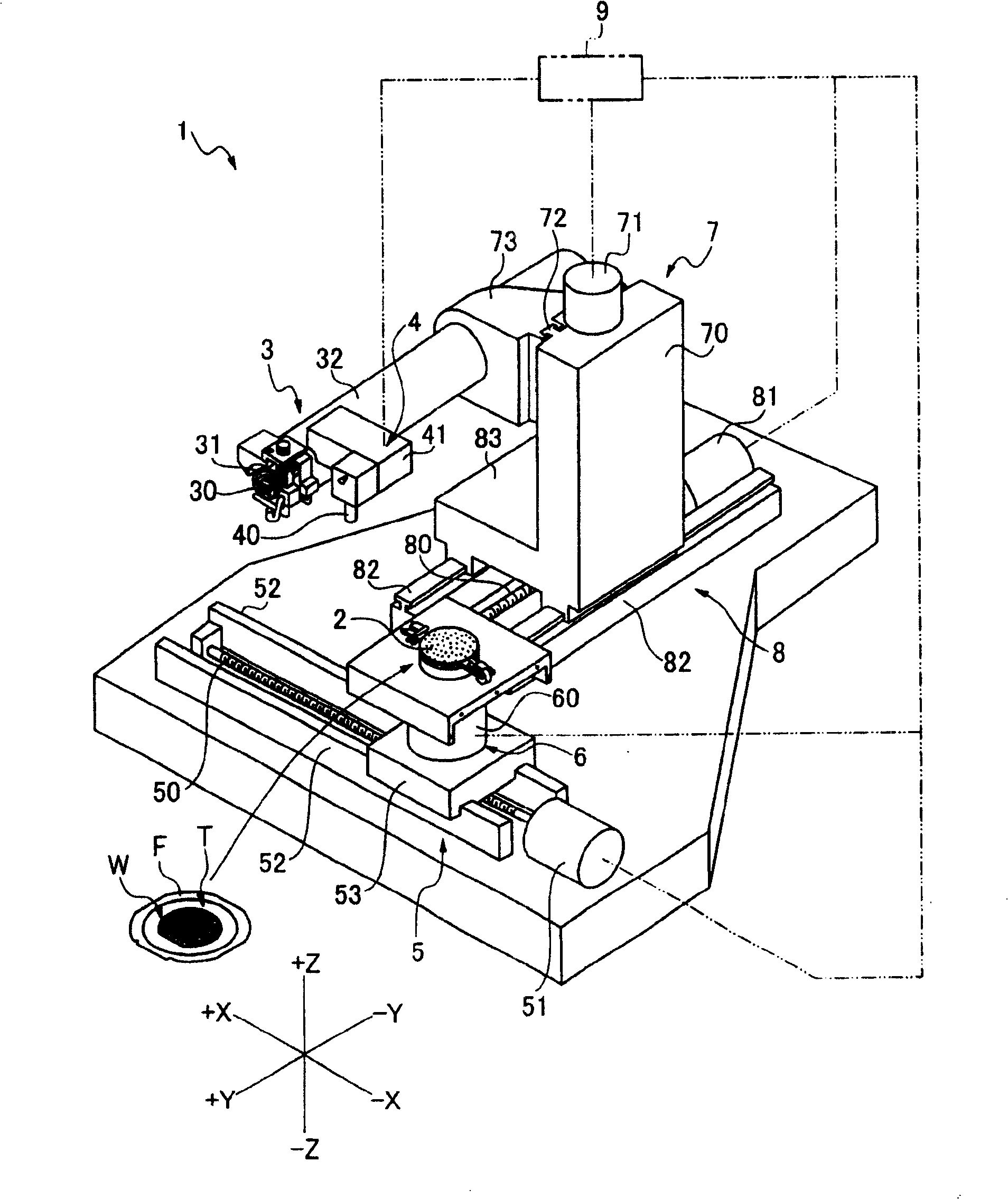

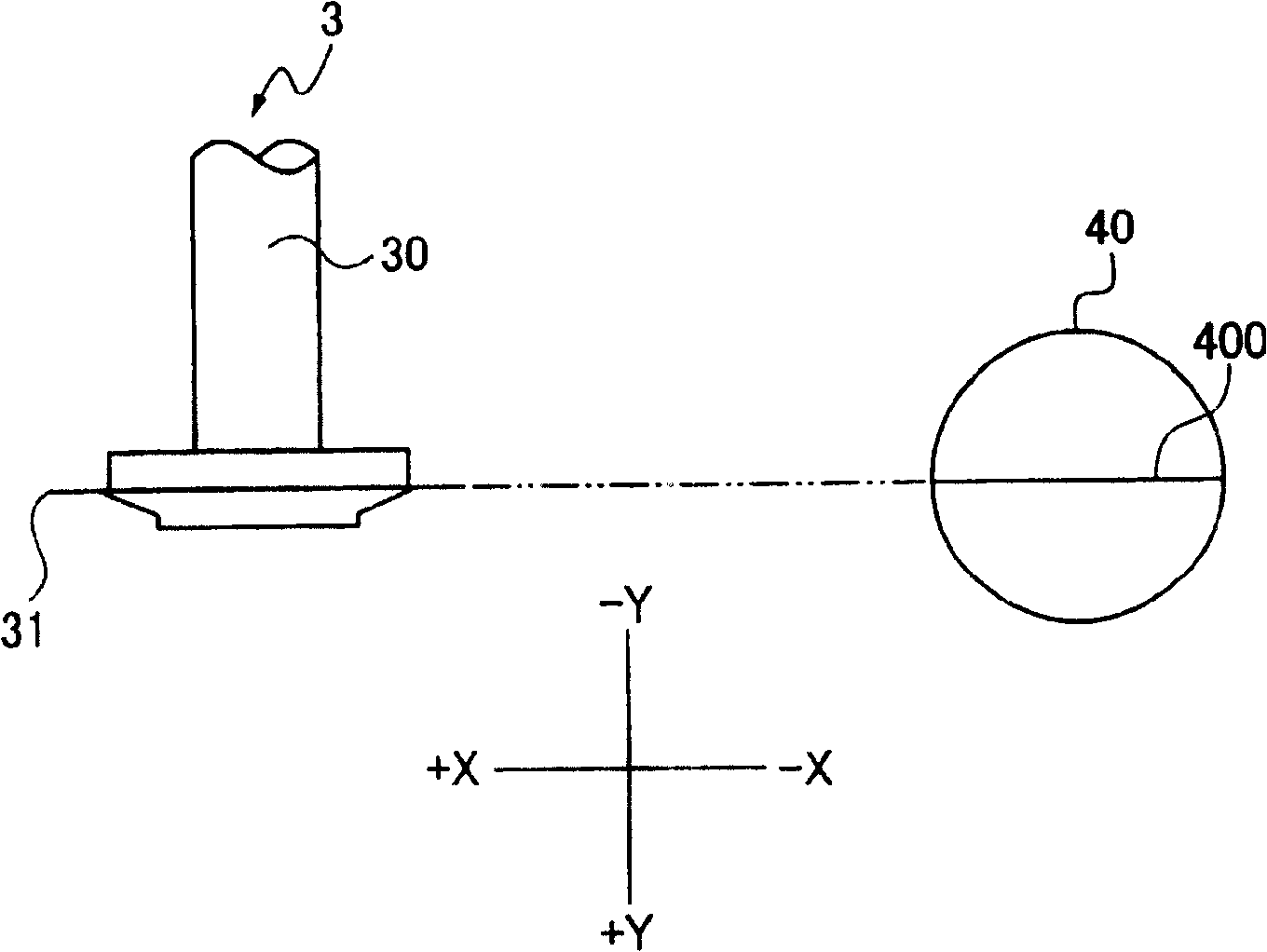

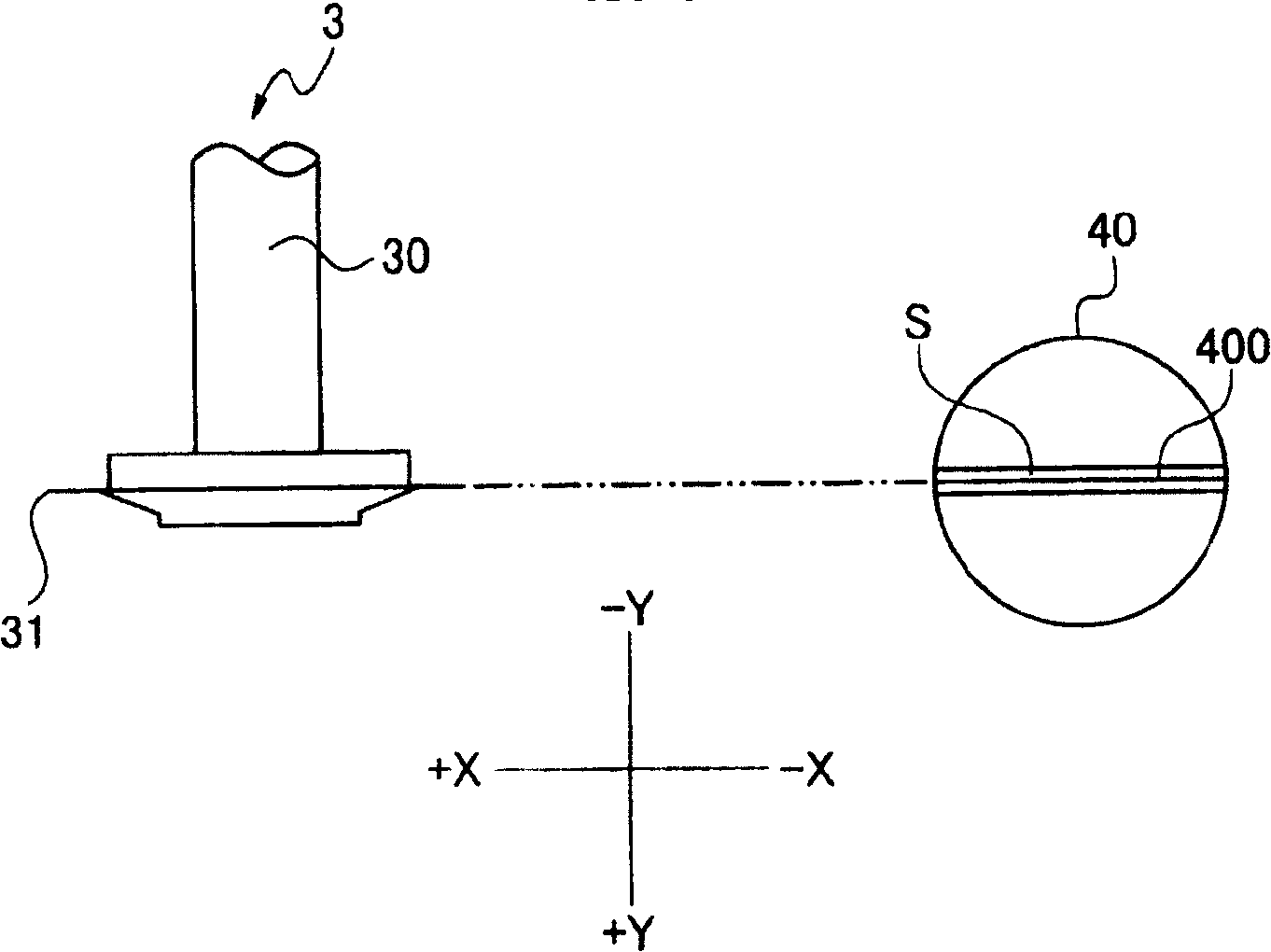

[0025] figure 1 The cutting device 1 shown is an example of the device used in the embodiment of the present invention, and is equipped with a suction cup table 2 holding a plate-shaped object, and a cutting blade 31 for cutting a plate-shaped object held on the suction cup table 2. The cutting mechanism 3 and the alignment mechanism 4 that have an optical system 40 that forms a reference line for positioning and can detect a planned cutting area of a plate-shaped object.

[0026] The suction cup table 2 can be moved along the X-axis direction by the X-axis feed mechanism 5 and can be rotated by the rotary drive mechanism 6 at the same time. The chuck table feeding mechanism 5 is composed of a ball screw 50 arranged in the X-axis direction, a driving source 51 connected to one end of the ball screw 50 to rotate the ball screw 50 , and a pair of ball screws arranged parallel to the ball screw 50 . A guide rail 52 and a movable base 53 that is slidably engaged with the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com