Device for hot dip coating metal strands

A metal strip, hot-dip plating technology, applied in the field of metal strips, can solve problems such as strip surface damage, and achieve the effect of improving the adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

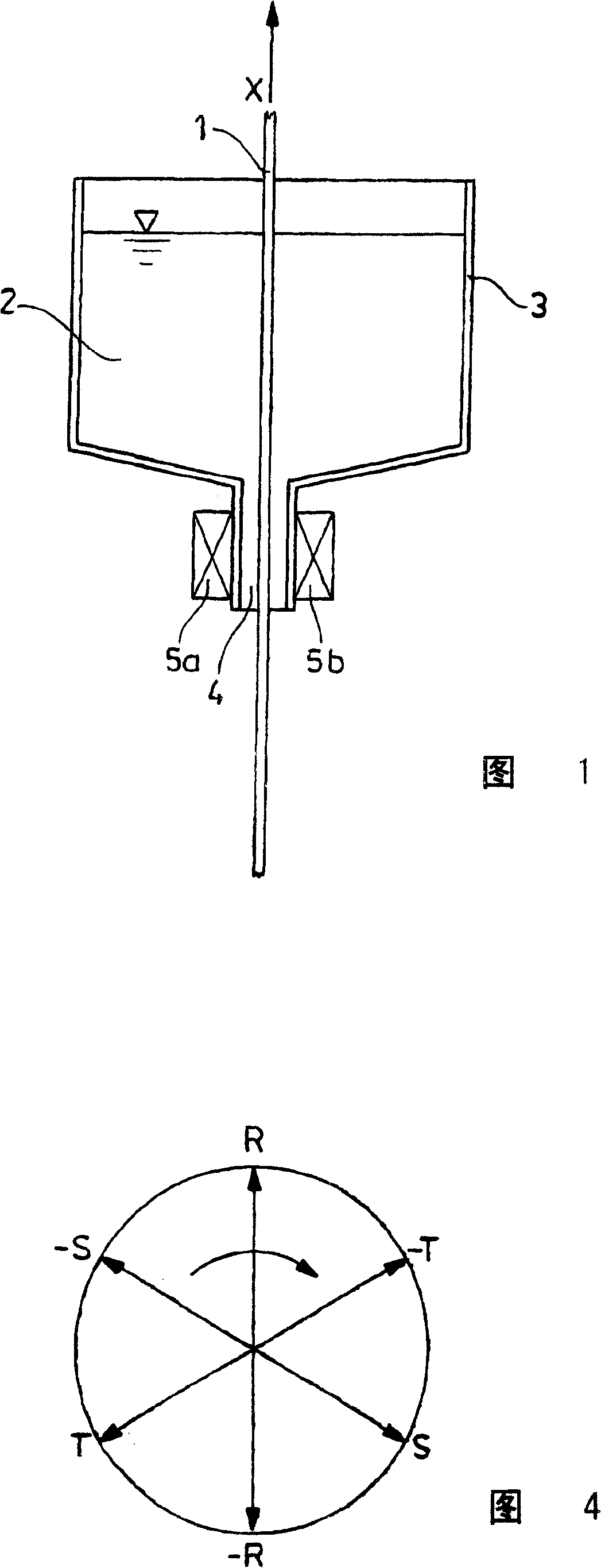

[0030] Figure 1 shows the principle of hot-dip coating a metal strip 1, especially a steel strip. The metal strip 1 to be coated enters the guide channel 4 of the coating device vertically from below. The guide channel 4 forms the lower end of the container 3, which contains the coating metal 2 in the liquid state. The metal strip 1 is guided vertically upward in the movement direction X. In order to prevent the liquid coating metal 2 from flowing out of the container 3, an electromagnetic sensor is arranged in the position of the guide channel 4. The inductor is composed of two halves 5a and 5b, one of which is arranged on each side of the metal strip 1. An electromagnetic moving field is generated in the electromagnetic sensor 5, which resists the liquid coating metal 2 in the blocking container 3 and prevents it from flowing out.

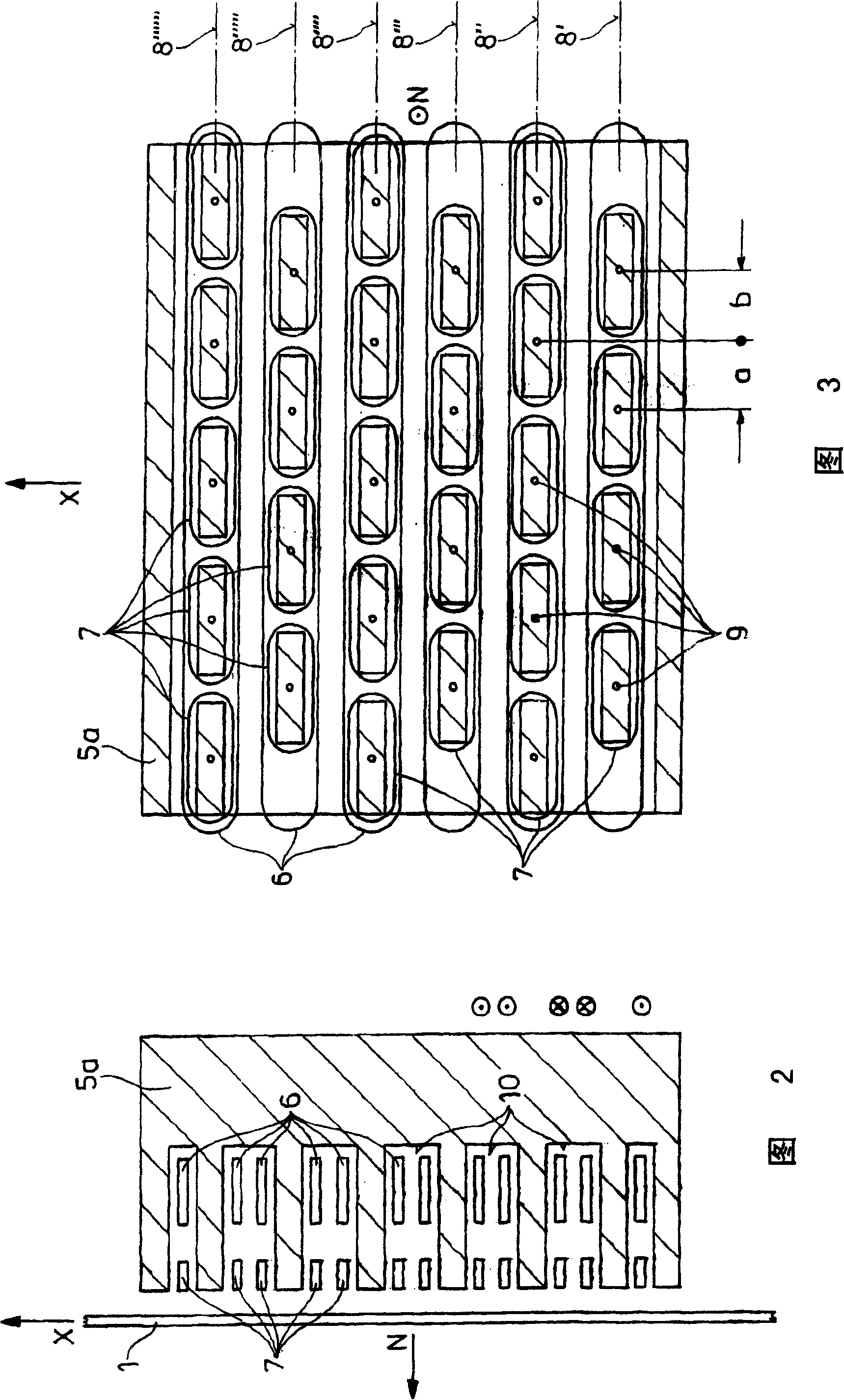

[0031] The exact configuration of the electromagnetic inductor 5 can be seen in FIGS. 2 and 3. What is shown is only one of two symmetrically formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com