Platform device conveying roller

A platform device and roller technology, applied in loading/unloading, conveyor objects, transportation and packaging, etc., can solve the problems of small transmission force, complex platform structure, inconvenient maintenance, etc., to improve reliability and effectiveness, platform device Simple structure, flexible and convenient correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

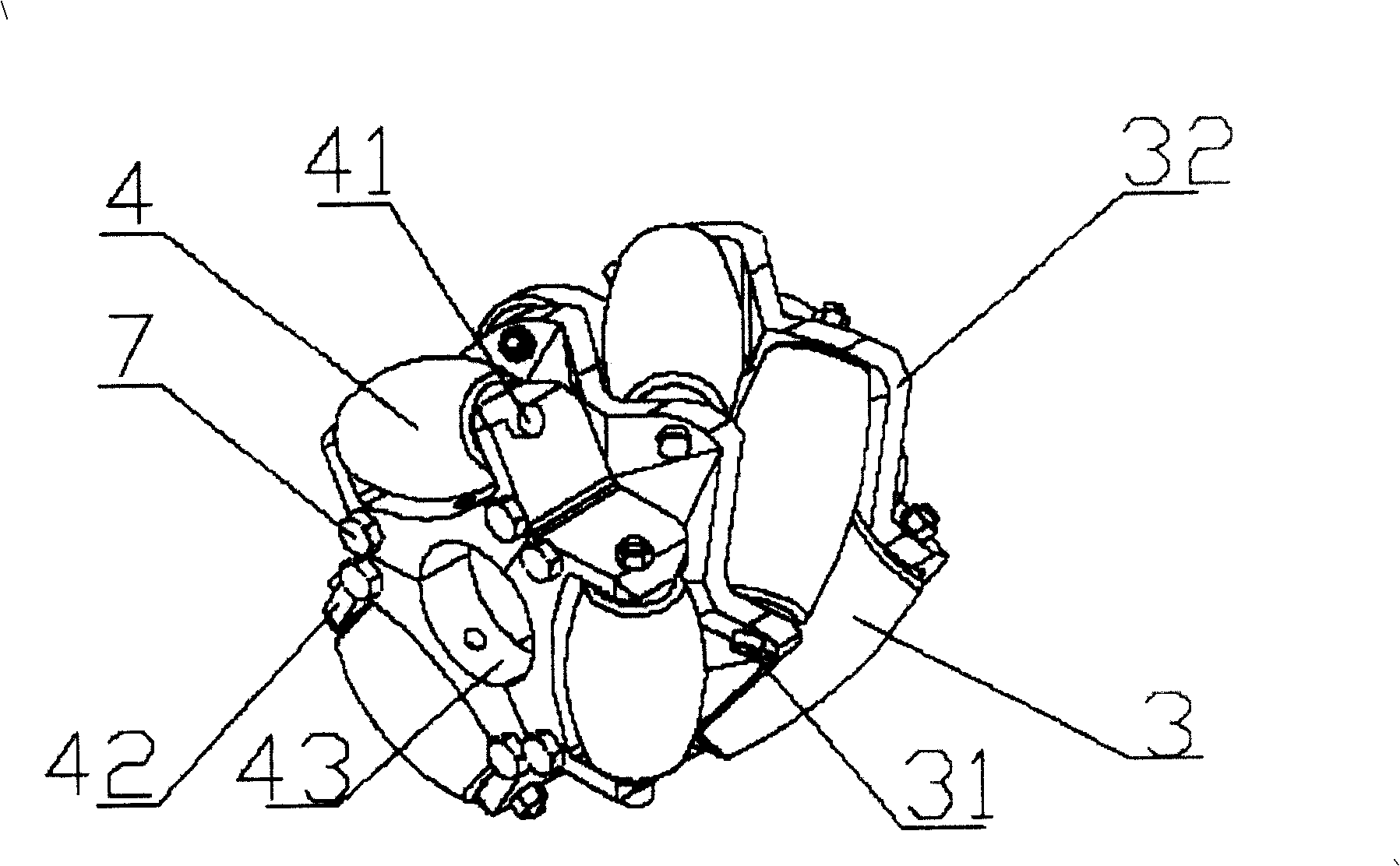

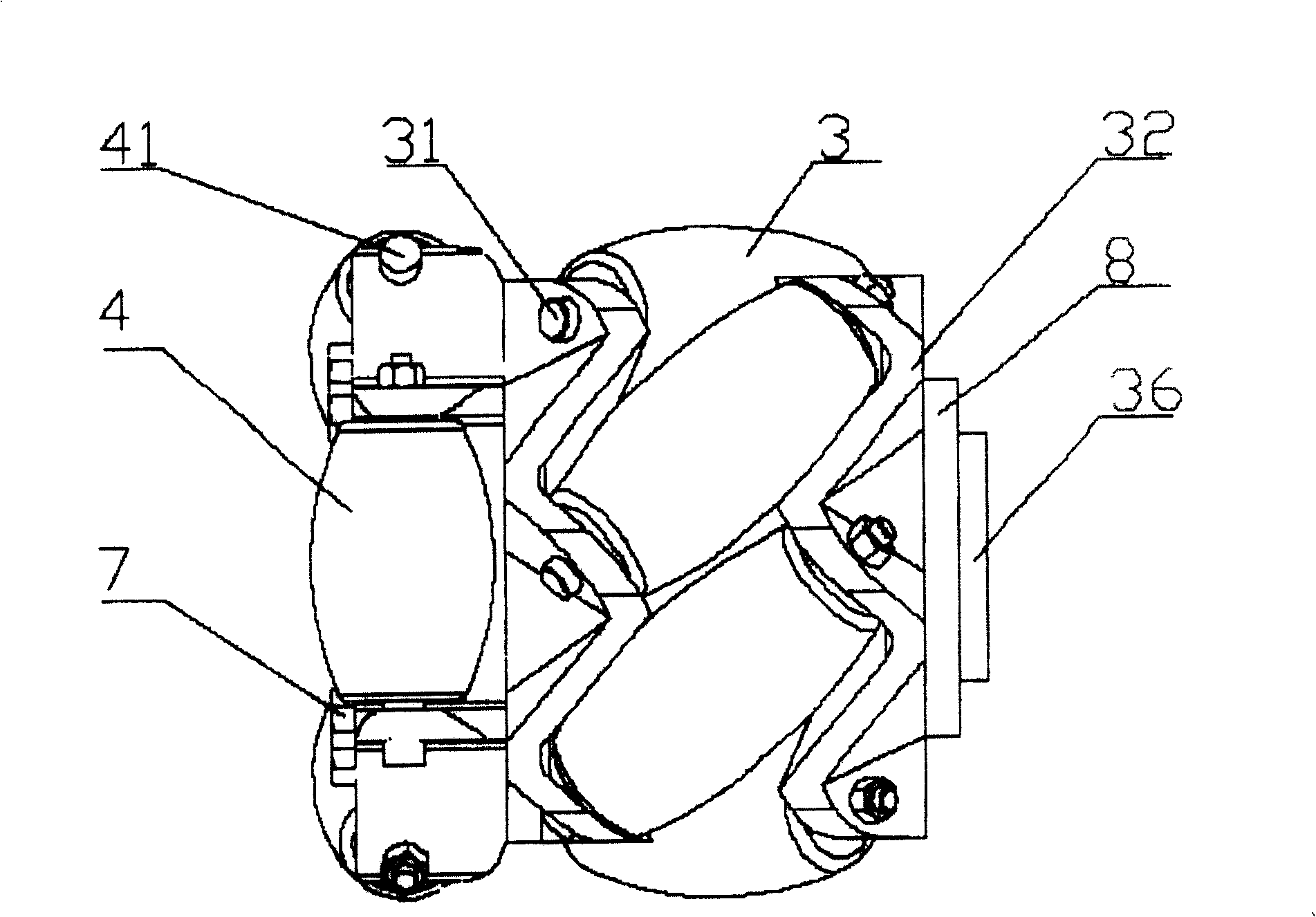

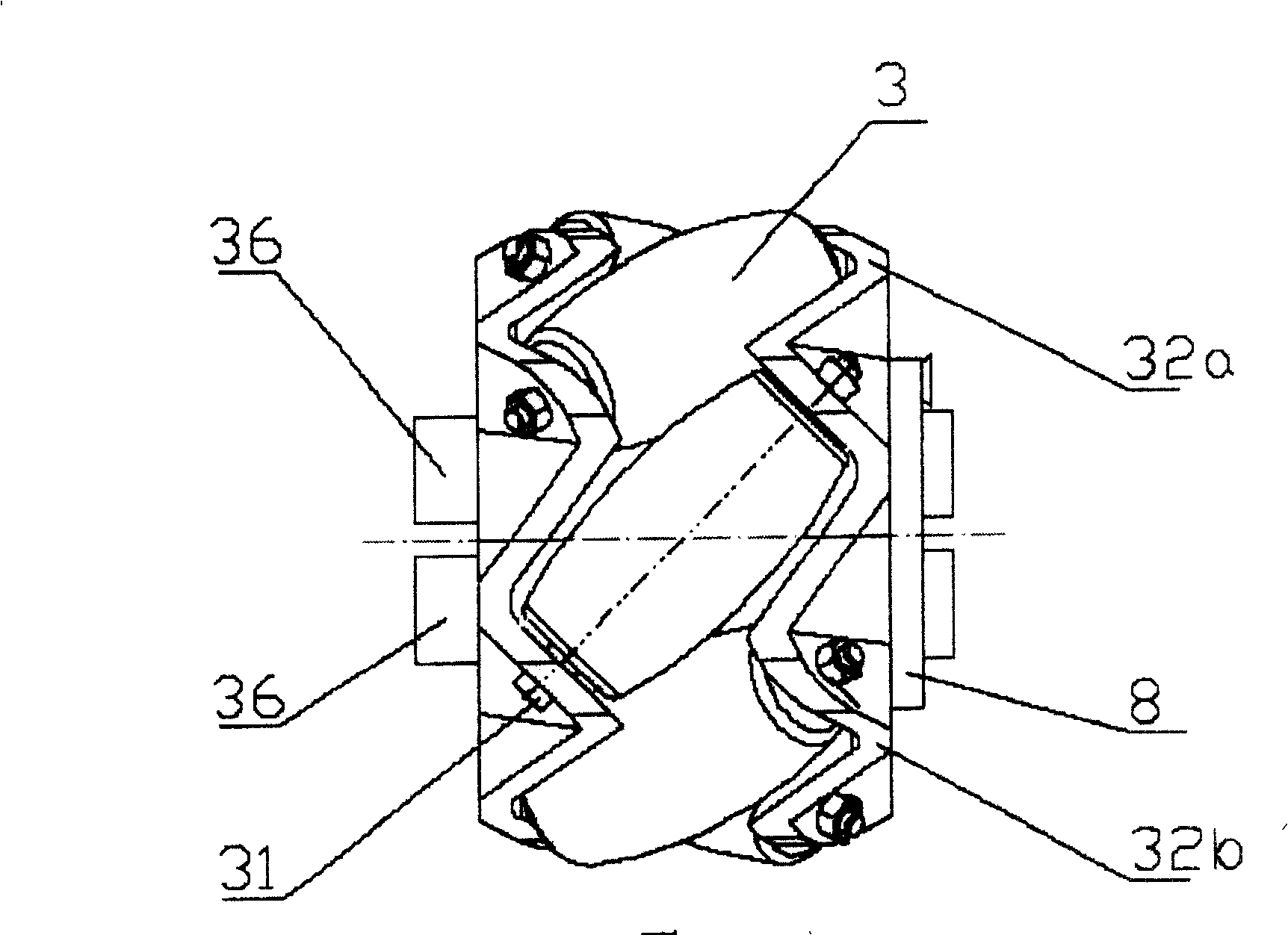

[0024] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , among Fig. 7, Fig. 8, the present invention is made up of roller axle frame, roller rotating shaft, roller, and the middle part of roller axle frame is provided with a shaft hole 33, and shaft hole 33 is used for installing main shaft 10, and roller shaft The frame is a rotary assembly composed of split shaft frames. It is composed of 45° roller shaft frame 32 and 90° roller shaft frame 42 arranged side by side. The 45° roller shaft frame 32 is located on the 90° roller shaft frame 42. On the right side, the 45° roller axle frame 32 is a combination of two 45° roller half axle frames 32a and 45° roller half axle frames 32b arranged around the main axis, and the two roller half axle frames 32a, 32b There are fixed bolt holes 35 and key pin holes 34 connected to the main shaft 10 on both ends of the axial direction, and six 45° rollers are evenly installed side by side on the 45° roller brack...

Embodiment 2

[0027]Embodiment 2: The present invention is composed of a roller shaft frame, a roller rotating shaft, and rollers. A shaft hole 33 is provided in the middle of the roller shaft frame. The shaft hole 33 is used to install the main shaft 10, and the roller shaft frame is a split body. The rotary assembly composed of pedestals is composed of 45° roller pedestals 32 and 90° roller pedestals 42 arranged side by side. The 45° roller pedestals 32 are located on the left side of the 90° roller pedestals 42. The roller shaft frame 32 is a combination of two 45° roller half shaft frames 32a and 45° roller half shaft frames 32b arranged around the main axis, and the axial ends of the two roller half shaft frames 32a and 32b There are fixed bolt holes 35 and key pin holes 34 connected with the main shaft 10, and six 45° rollers 3, 45° are evenly installed side by side on the 45° roller shaft frame 32 around the main axis via the 45° roller rotation shaft 31 The angle between the roller ...

Embodiment 3

[0029] The present invention is composed of a roller shaft frame, a roller rotating shaft, and a roller. A shaft hole 33 is provided in the middle of the roller shaft frame. The shaft hole 33 is used to install the main shaft 10. The roller shaft frame is composed of a split shaft frame. The rotary assembly is composed of a 45° roller shaft frame 32 and two 90° roller shaft frames 42 arranged side by side. A 90° roller shaft frame 42 is respectively installed at the left and right ends of the 45° roller shaft frame 32. The 45° roller axle frame 32 is a combination of two 45° roller half axle frames 32a and 45° roller half axle frames 32b arranged around the main axis. The end face is provided with a fixed bolt hole 35 and a key pin hole 34 connected with the main shaft 10. On the 45° roller shaft frame 32, six 45° rollers 3, 45 are evenly installed side by side around the main axis via the 45° roller rotation axis 31. The included angle between the roller rotation axis 31 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com