Cone type movable crushing station

A mobile crushing and crushing station technology, applied in grain processing, etc., can solve the problems of unreliable improvement, complex structure, large volume, etc., and achieve the effect of fast and convenient mobile transfer, flexible and convenient transmission, and streamlined structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to specific embodiments and drawings. In the following description, more details are set forth in order to fully understand the present invention. However, the present invention can obviously be implemented in many other ways different from the description here. Those skilled in the art can make similar promotion and deduction according to actual application conditions without violating the connotation of the present invention. Therefore, the content of this specific embodiment should not limit the protection scope of the present invention.

[0024] Specifically, the present invention proposes the following specific embodiments:

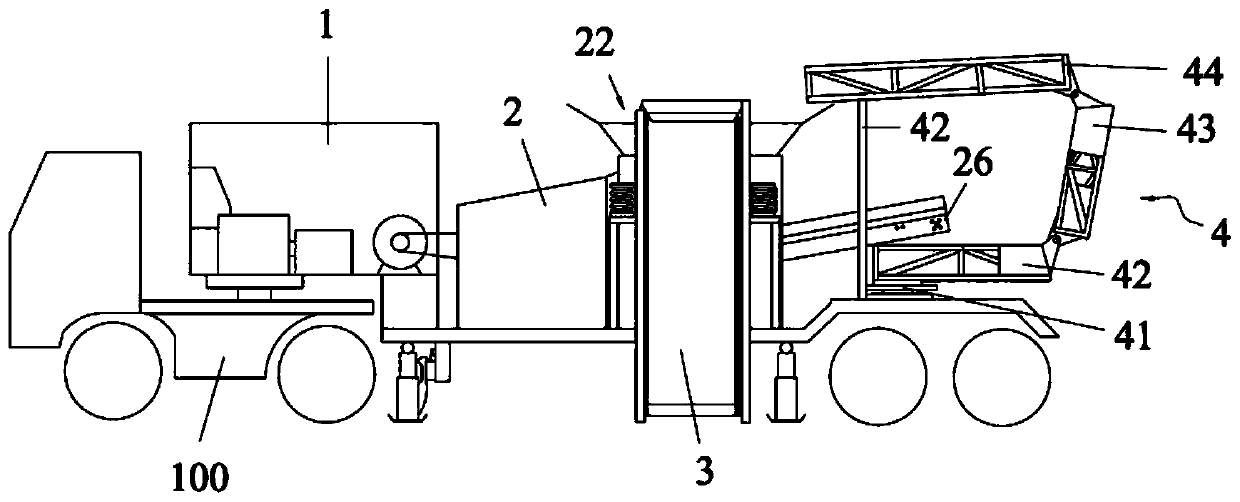

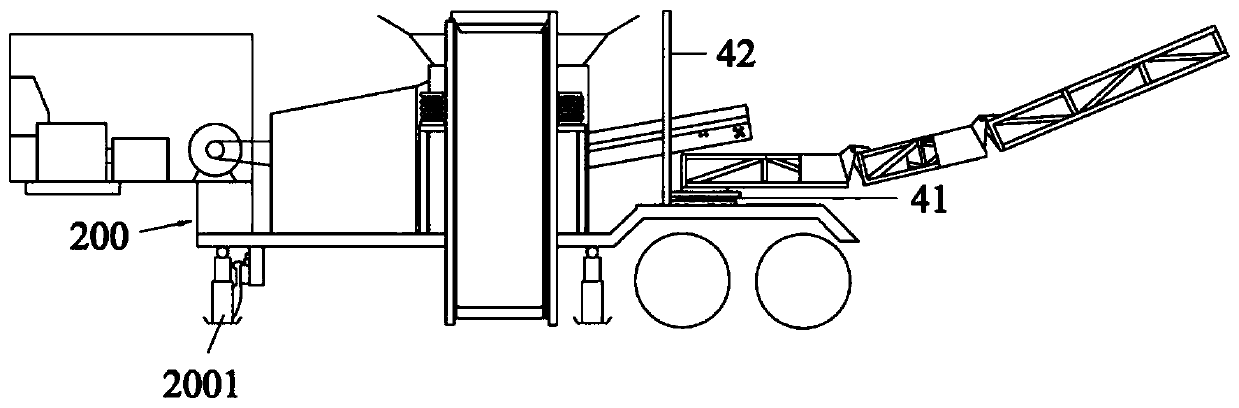

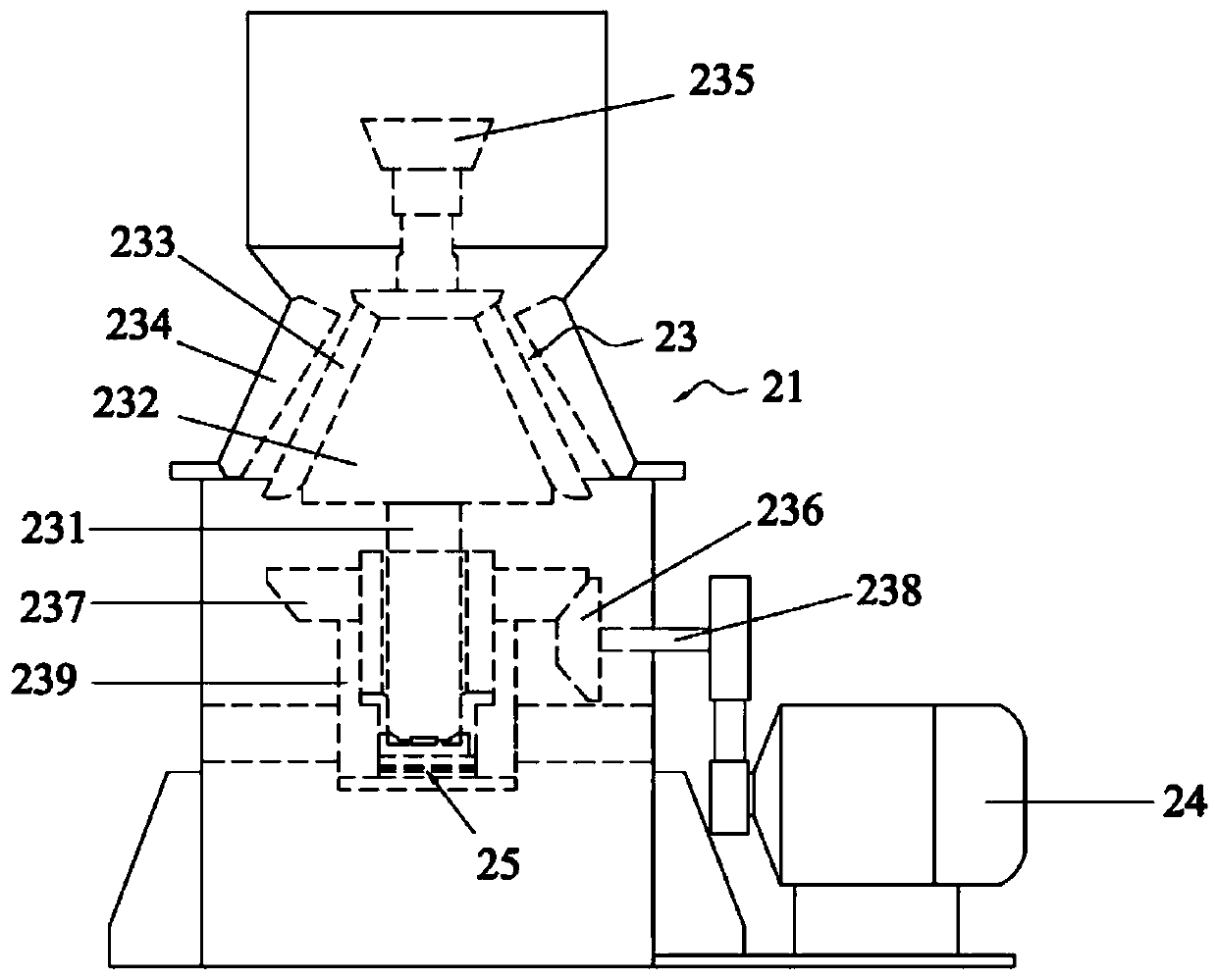

[0025] reference Figure 1 to Figure 3 As shown, the cone-type mobile crushing station provided by this embodiment includes a tractor 100 and a crushing station towed by it. The tractor 100 and the crushing station adopt a detachable connection structure for the crushing station t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com