Battery and method of producing the same

A technology for batteries and battery containers, which can be used in secondary battery manufacturing, final product manufacturing, battery pack components, etc., and can solve problems such as difficulties and affecting the connecting portion 7c.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

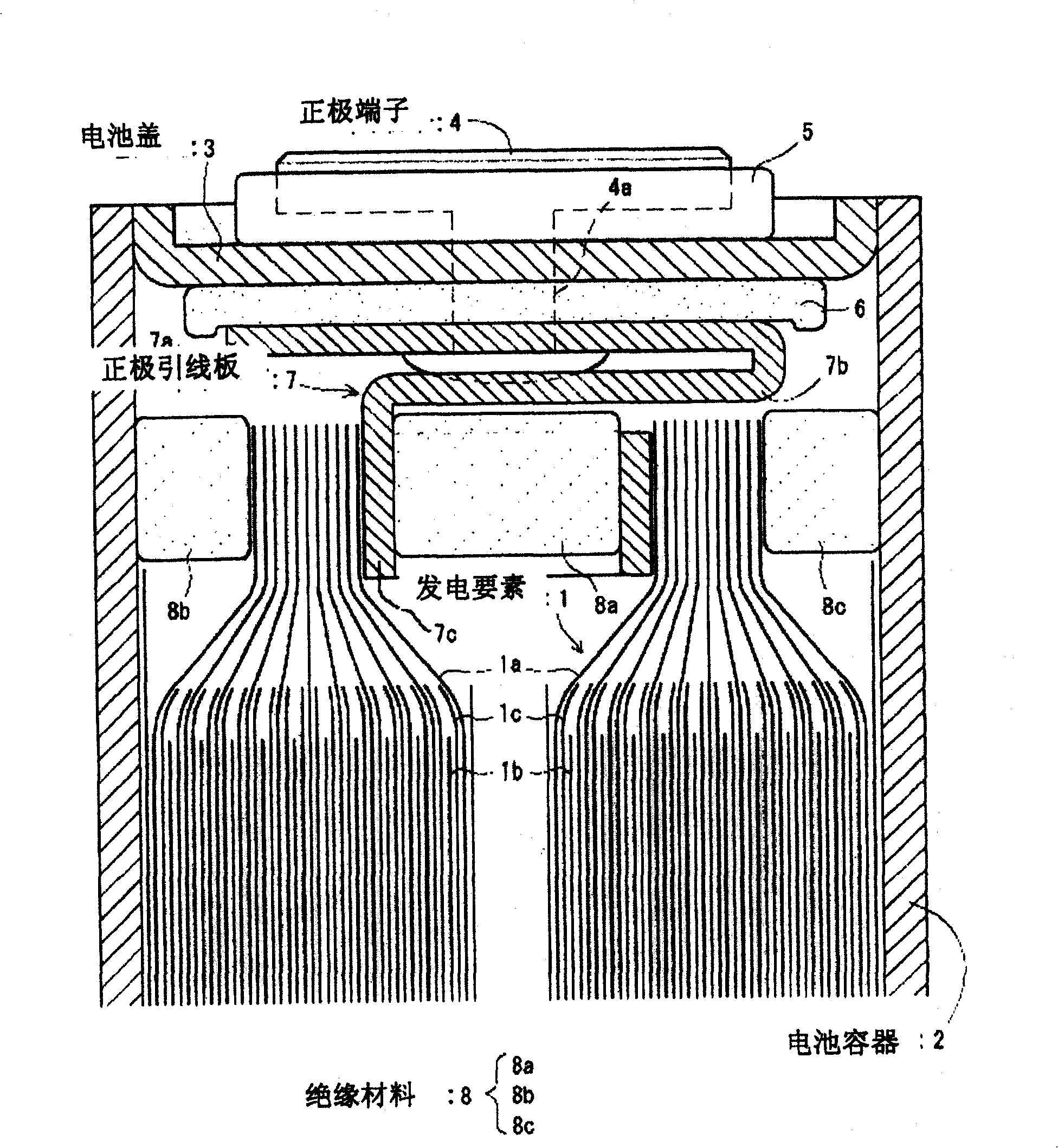

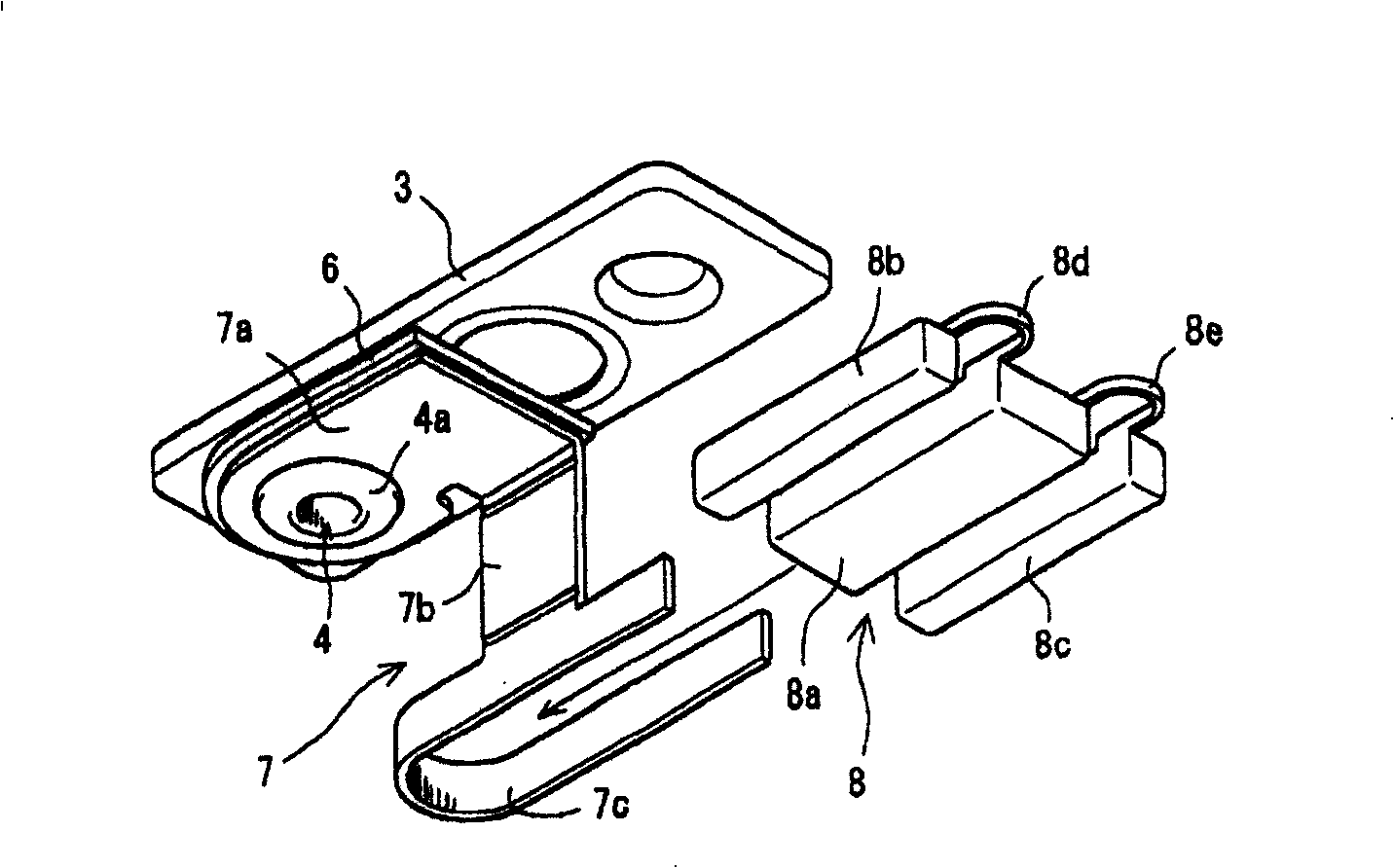

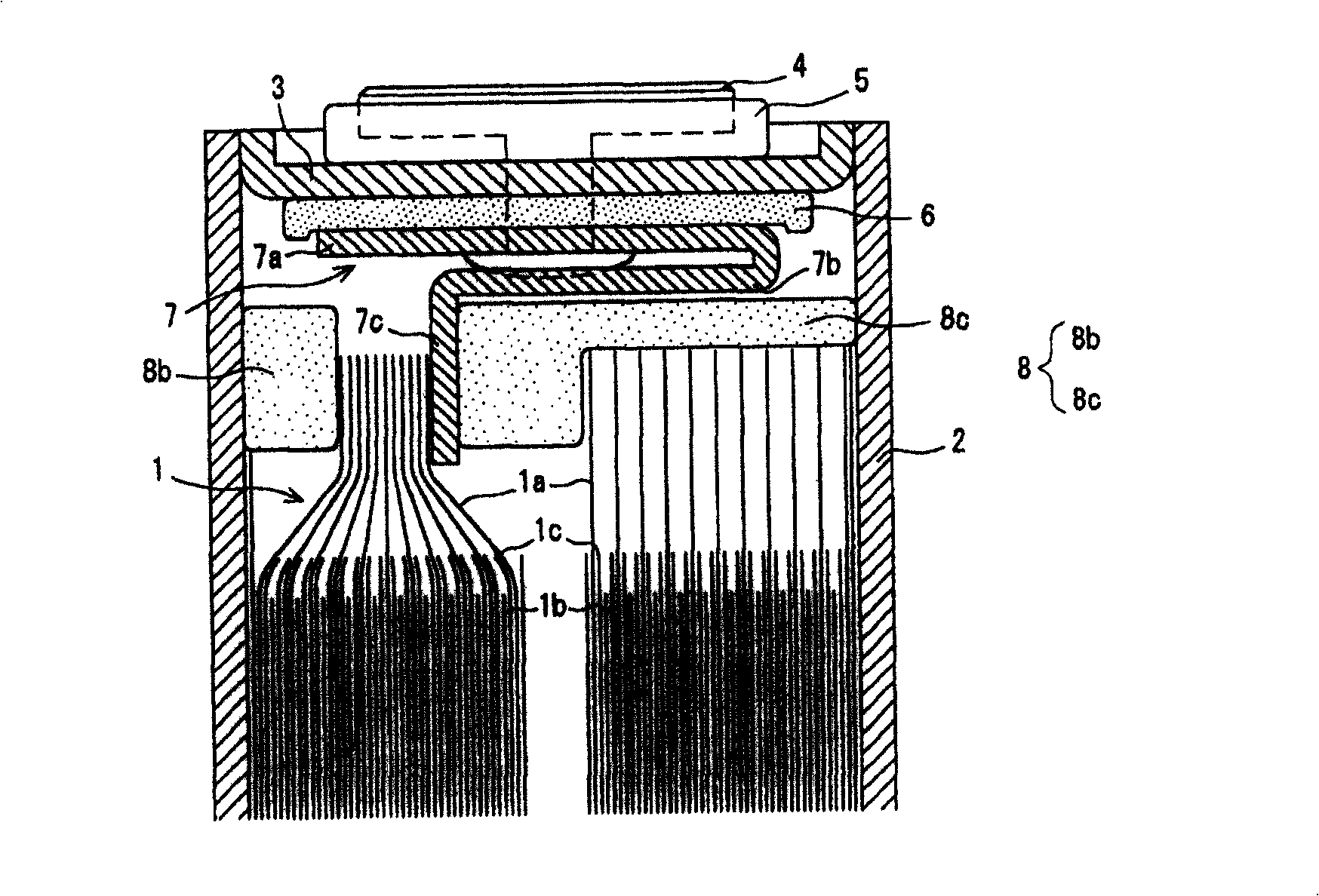

[0028] Here, referring to the embodiment of the present invention Figure 1 ~ Figure 3 Be explained.

[0029] This specific implementation will be as Figure 4 ~ Figure 5 A non-aqueous electrolyte secondary battery having basically the same structure as the conventional example will be described. Moreover, even in Figure 1 ~ Figure 3 in, such as Figure 4 ~ Figure 5 Structural components shown having the same functions as those of the prior example are given the same reference numerals.

[0030] The structures of the power generating element 1, the battery container 2, and the battery cover 3 of the non-aqueous electrolyte secondary battery in this embodiment are the same as those of the conventional example. In addition, the positive terminal 4 on the battery cover 3 is insulated and sealed by the terminal insulating sealing materials 5 and 6, and the protrusion 4a of the positive terminal 4 is connected and fixed with the positive lead plate 7 by riveting. This structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com