Light waveguide-layer inputting-outputting coupling interface assembly in EO-PCB board and its production

A technology of interface components and optical waveguides, which is applied in the direction of coupling of optical waveguides to achieve the effect of convenient assembly and convenient testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

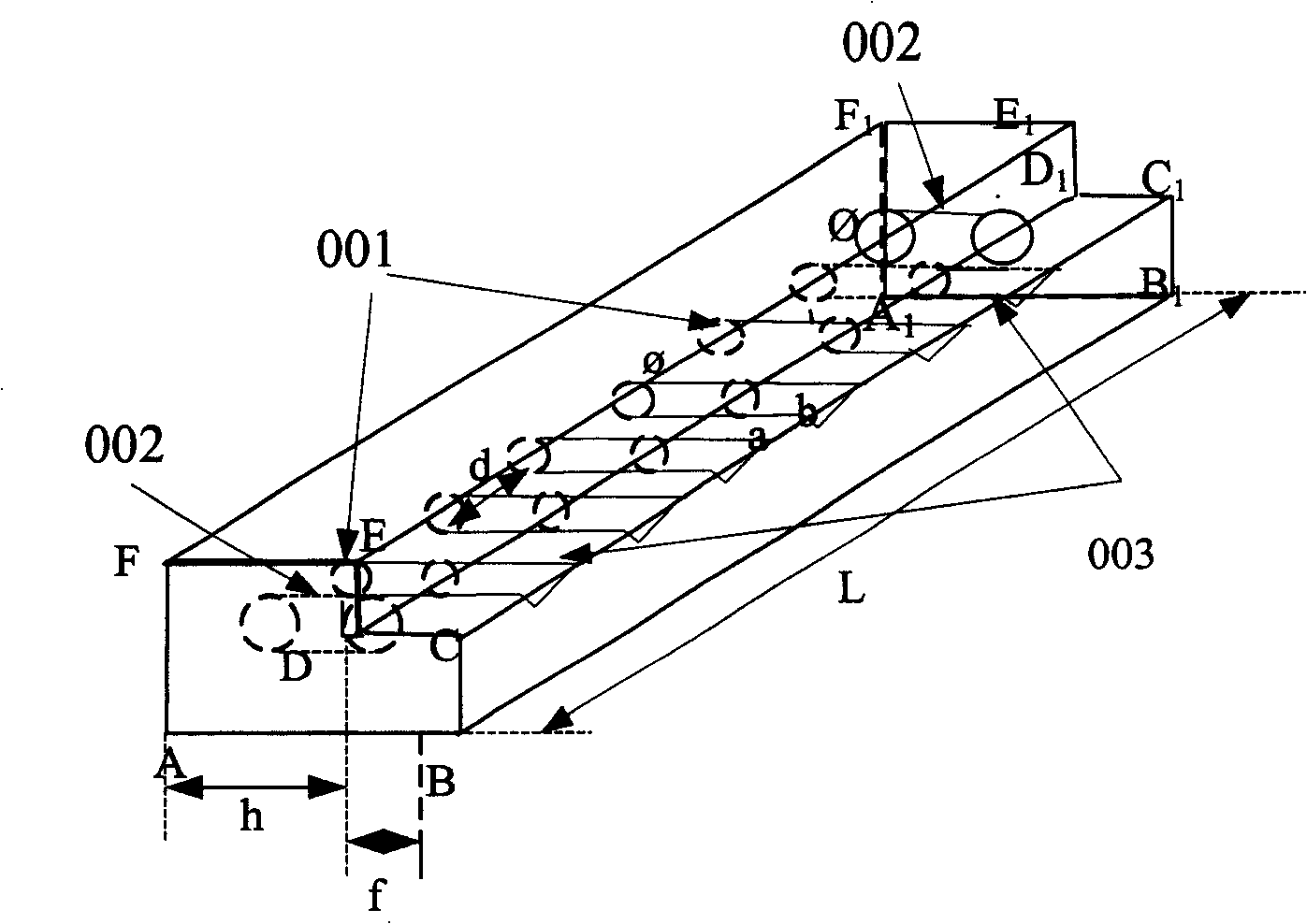

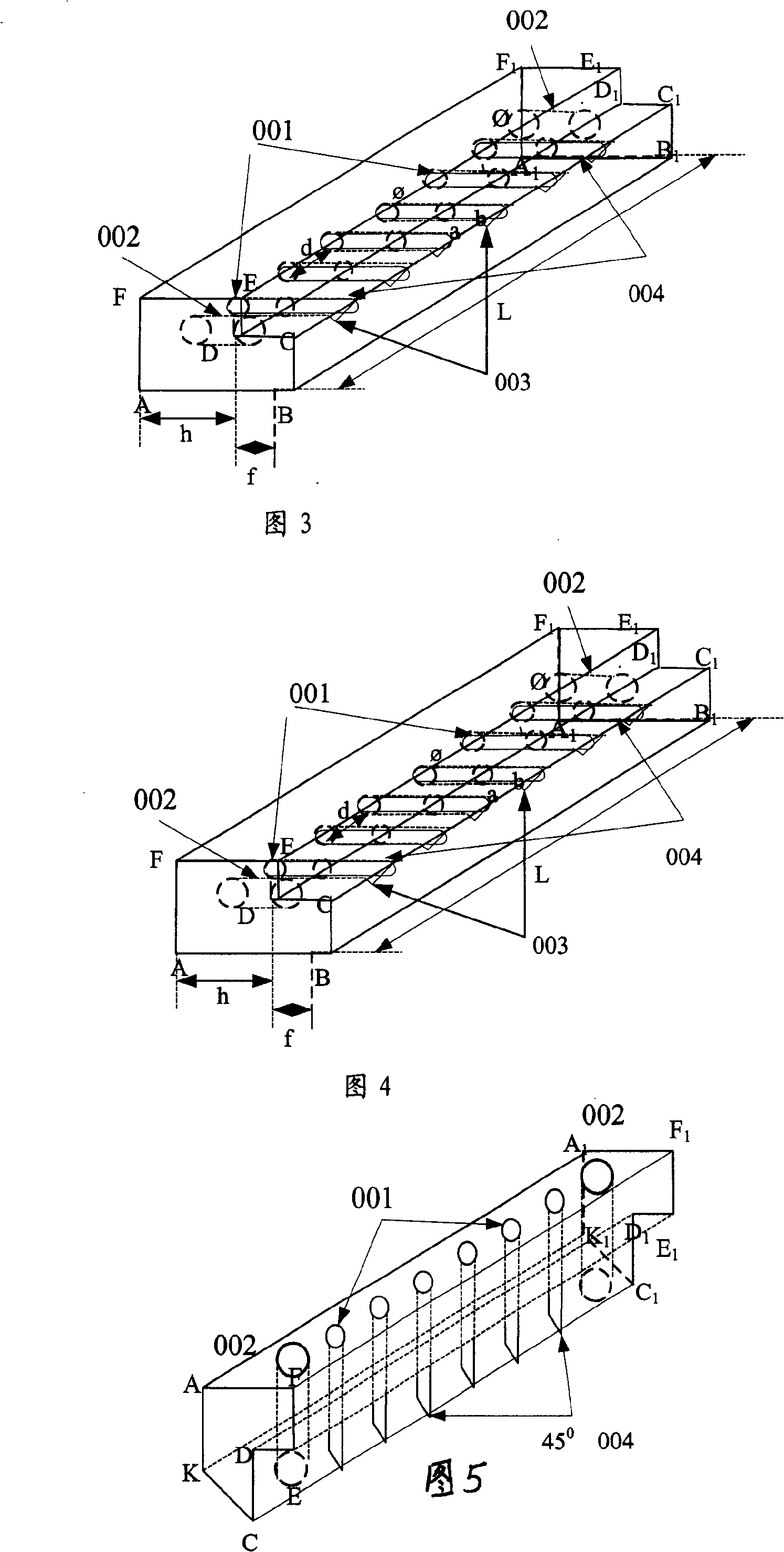

[0028] The optical waveguide layer input and output optical coupling interface assembly in the EO-PCB board of the present invention is an integrated module structure, such as figure 2shown. First design the mold, the plastic module produced by the mold has the following characteristics: the plastic module is a two-step ladder module, the side view is ABCDEF, and A1B1C1D1E1F1, divided into upper and lower steps, upper and lower steps The interface of the step surface is the central plane, and there are two types of through holes. The n through holes in the middle are optical fiber positioning holes 001, and the aperture diameter φ is about 126 μm. The two holes distributed on both sides are positioning pin holes 002, and the hole diameter Φ is about 0.7mm. These vias are centered at the interface DD of the second step 1 On the top, the upper and lower halves of the through hole are respectively in the upper and lower steps. On the surface of the lower step, along the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com