Anti-leakage earth work film reinforced with fiber knitting layer and its preparing process

A technology of fiber braided layer and geomembrane, applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of basic anti-seepage plastic film foundation leakage, time-consuming, troublesome, unreliable, etc. , to achieve the effect of improving the overall mechanical strength, increasing the bonding force and reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Geomembrane Examples

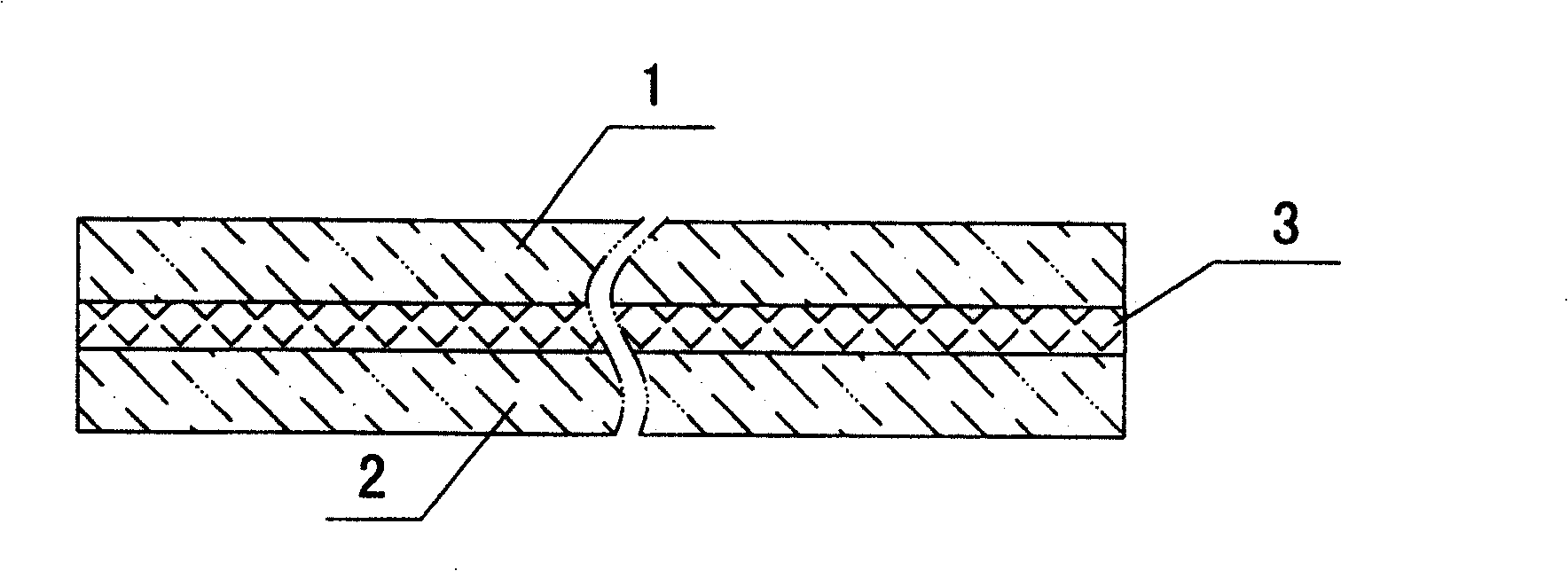

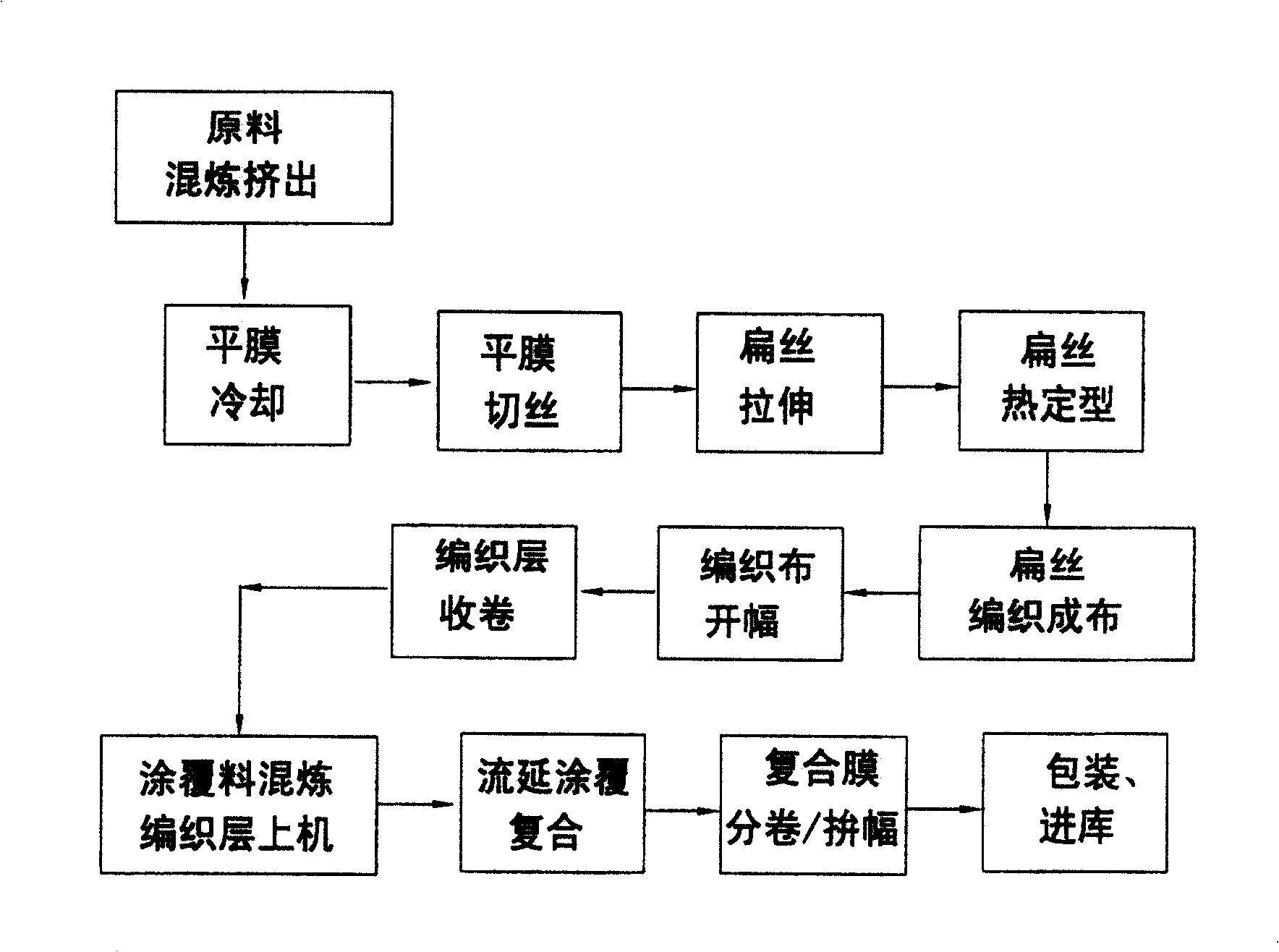

[0024] Such as figure 1 Shown: a geomembrane reinforced by a fiber braid layer of the present invention, the film comprises an upper membrane layer 1 and a lower membrane layer 2, the upper membrane layer 1 and the lower membrane layer 2 are made of the same or different materials, and the upper membrane layer 1 and the lower membrane layer 2 are made of the same or different materials. The lower membrane layer 2 has a core layer 3 of the same or different material as the upper membrane layer 1 and / or the lower membrane layer 2, and the core layer 3 of the geomembrane is a layer of flat fiber material with a width of 2.5 mm. The two sides of the braided layer 3 are bonded to the upper membrane layer 1 and the lower membrane layer 2 respectively; the geomembrane of the present invention is bonded and composited by the upper membrane layer 1, the braided layer 3 and the lower membrane layer 2 made.

[0025] The upper film layer 1 and the lower film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com