Bamboo splint braider

A braiding machine and bamboo sheet technology, applied in mechanical equipment, sugarcane machining and other directions, can solve problems such as affecting wiring, complicated wiring methods, disconnection, etc., so as to improve the speed of on-line wiring, facilitate on-line wiring, save time, and reduce The troublesome effect of disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

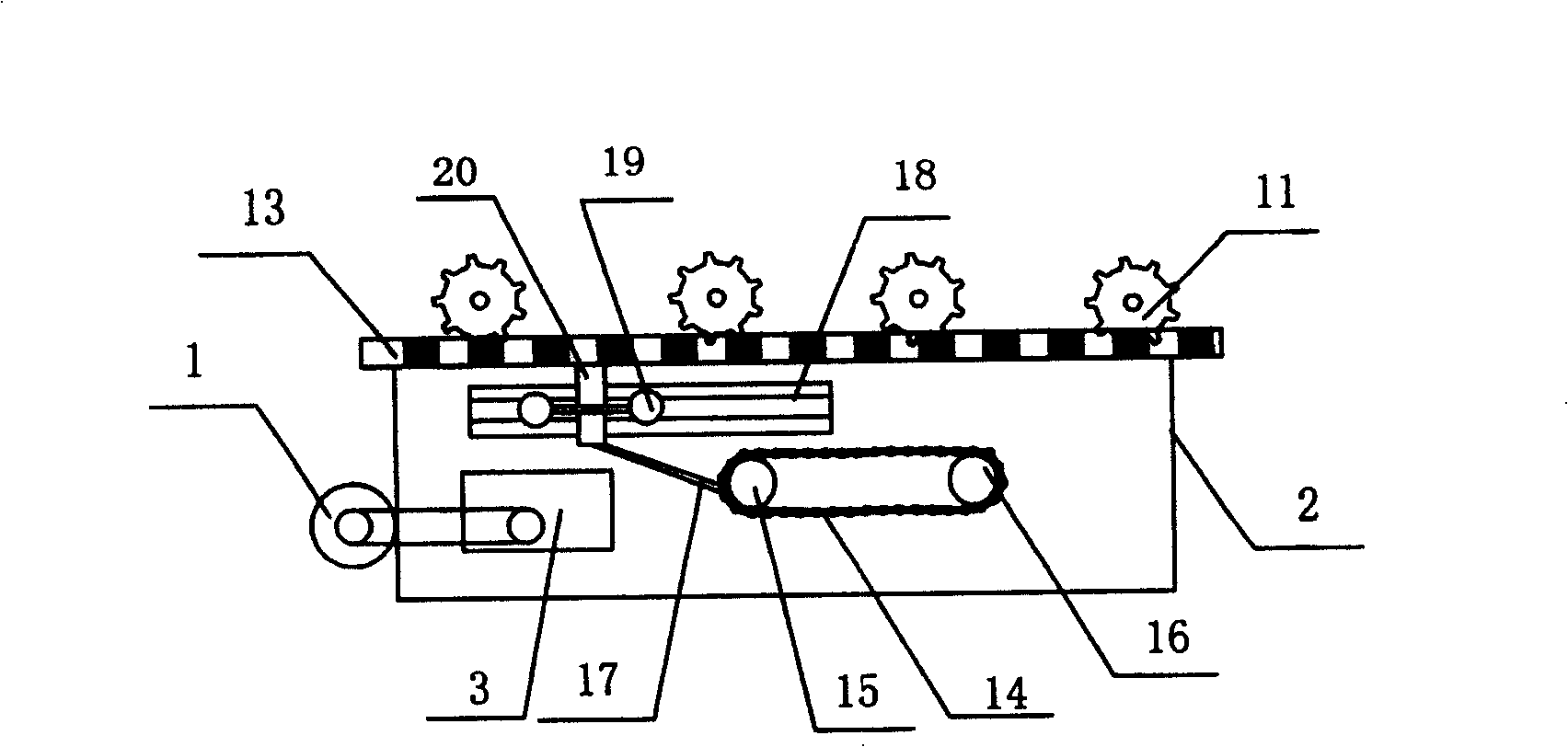

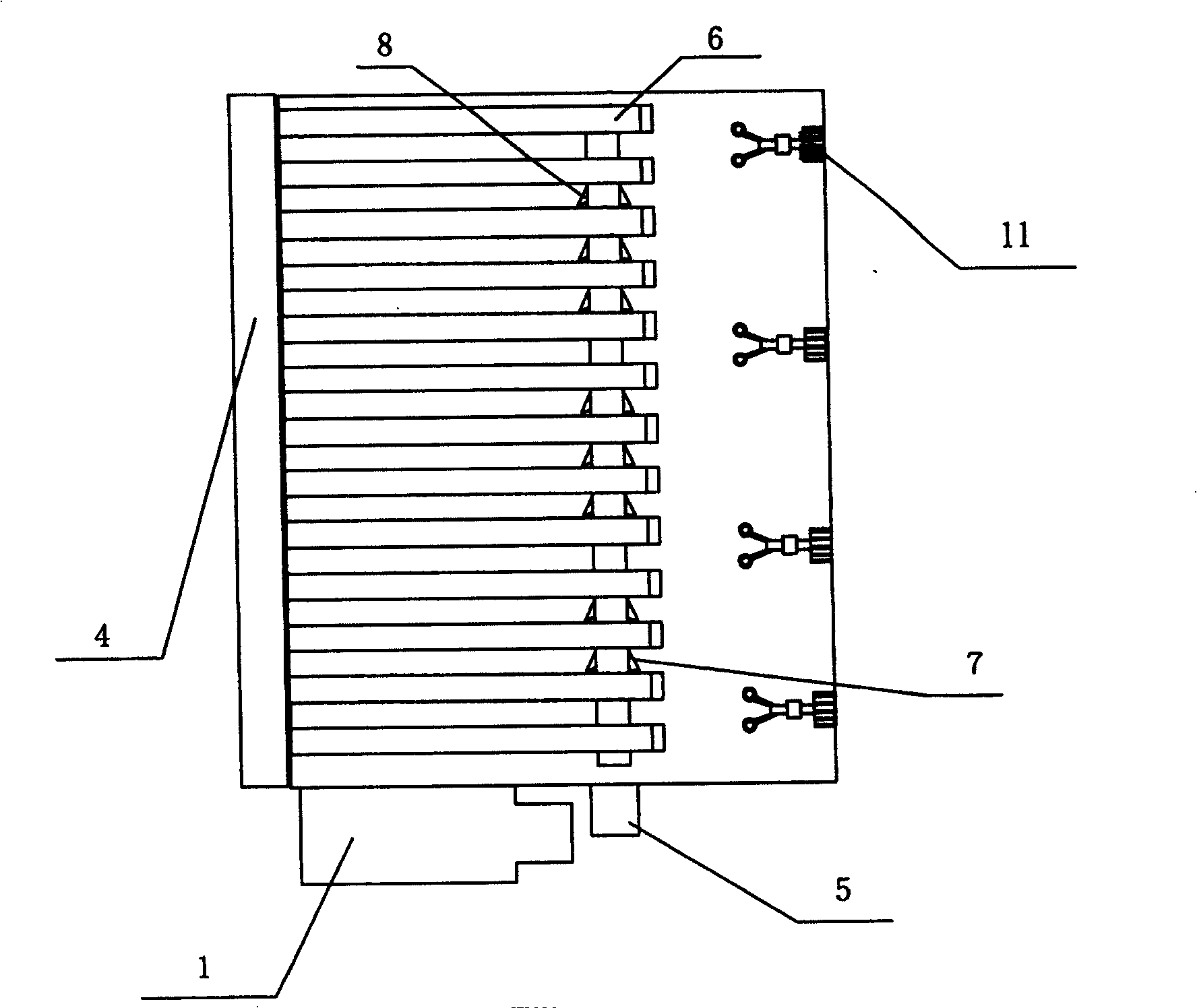

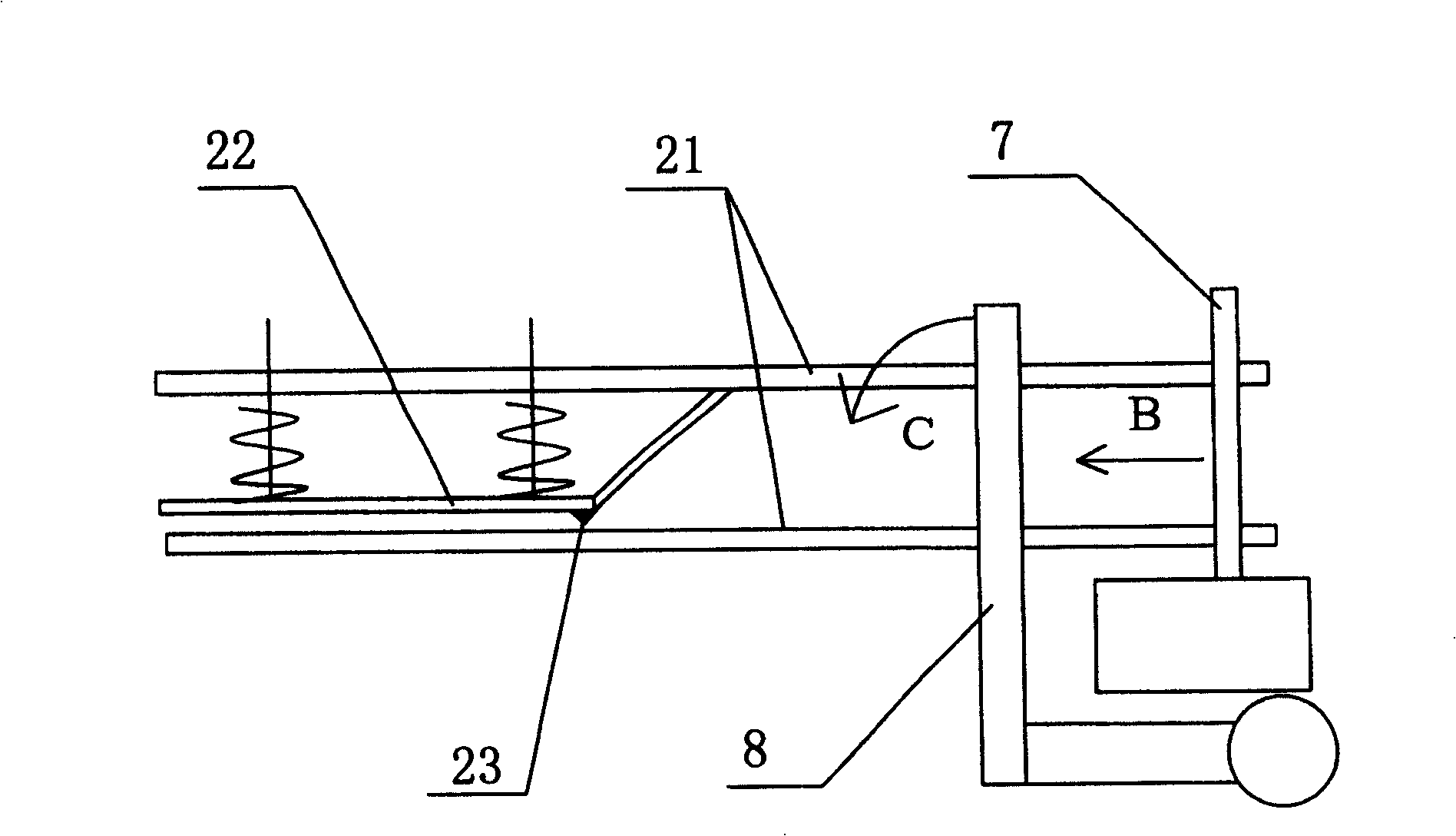

[0022] refer to figure 1 , figure 2 , image 3 , Figure 5 , a bamboo weaving machine, comprising a motor 1, a frame 2, a reduction box 3 installed on the frame 2, a transmission mechanism, a feeding mechanism, a bamboo mechanism, a weaving mechanism, and a discharge roller mechanism 4, and the motor 1 is connected The reduction box 3, the reduction box 3 respectively drives the described feeding mechanism, the raft leaning mechanism, the weaving mechanism and the discharging roller mechanism 4 through the transmission mechanism;

[0023] Described feeding mechanism comprises feeder 5 and feeding platform 6;

[0024] The strip leaning mechanism includes a strip leaning board 7 and a strip blocking board 8, the strip leaning board 7 is located on a side away from the discharge drum mechanism 4, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com