Dump Truck Screw Lifting System

A technology of dump trucks and lead screws, which is applied to the arrangement of loading and unloading vehicles, motor vehicles, and vehicles used for freight transportation. It can solve the problems of high risk and complicated production of hydraulic lifting systems, and avoid uneven distribution of shaft cores. , Guarantee the effect of safety and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

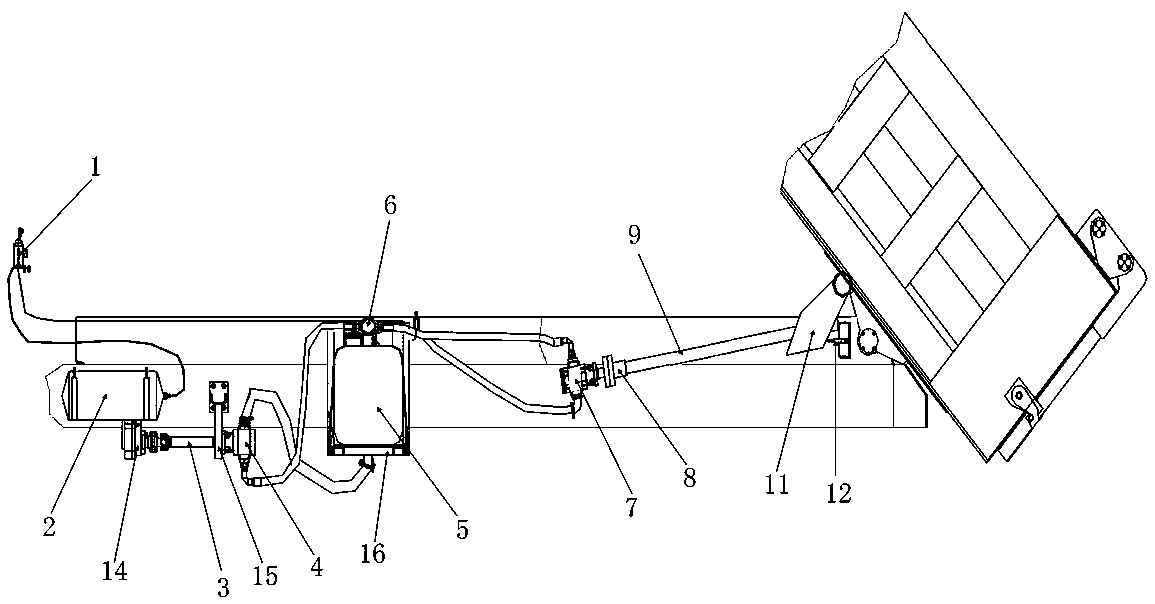

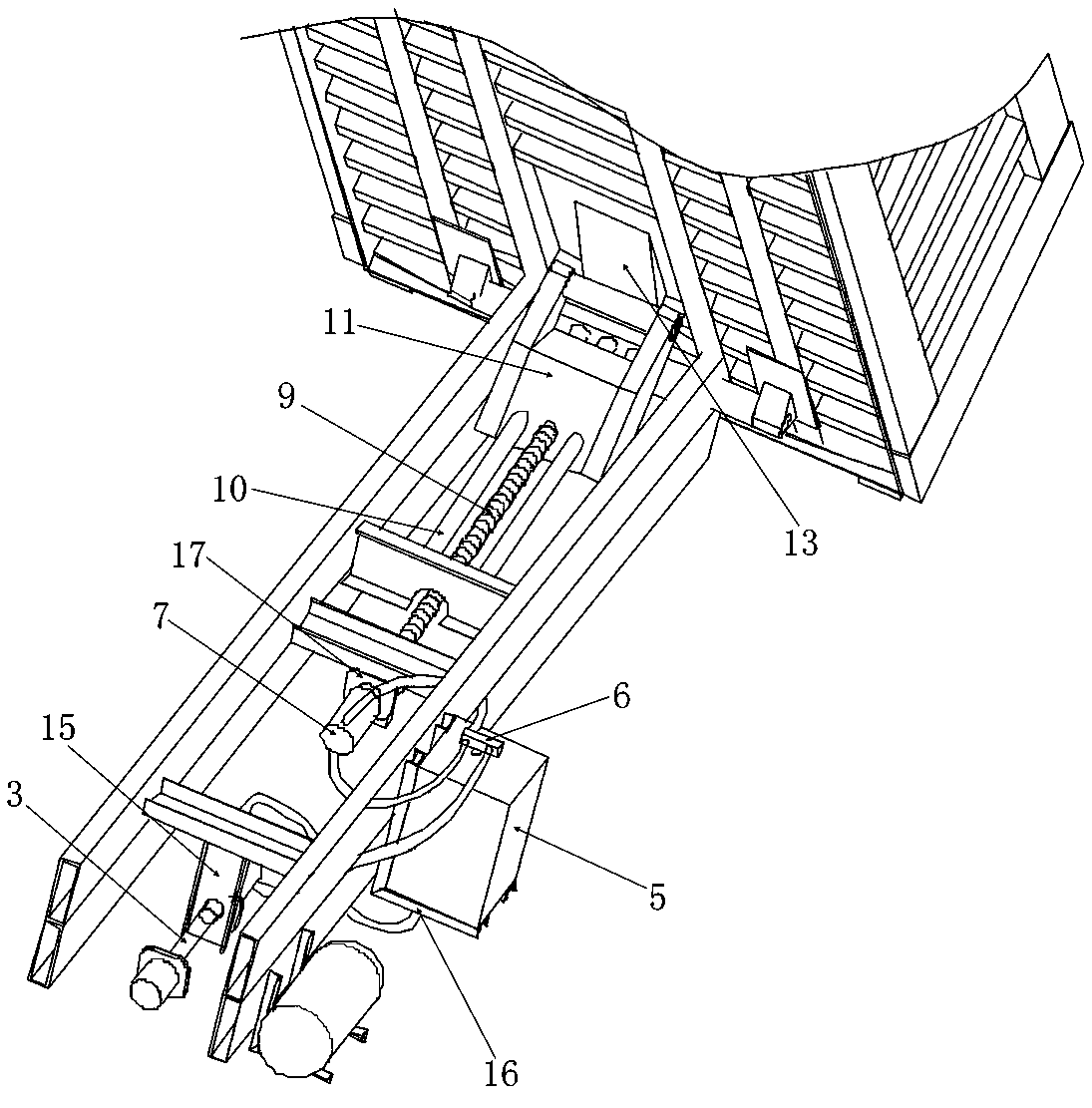

[0018] This lifting system is mainly used for light-weight front roof and 6*4 light-duty dump vehicles. The lifting system is composed of a hydraulic system assembly and a power transmission assembly.

[0019] Such as figure 1 , figure 2 As shown, the hydraulic system assembly is composed of a control valve 1, an air tank 2, an oil pump 4, a transmission shaft 3, a chassis power take-off 14, a fuel tank 5, a three-position four-way distribution valve 6 and a limit valve 12. The control valve 1 (two-position three-way directional control valve, normally open type) is arranged in the cab, the gas tank 2 is the gas tank that comes with the chassis of the car, and is arranged on the chassis beam, and the air inlet of the control valve 1 passes through the air pipeline Connect the gas tank 2, and the control valve 1 is connected to the three-position four-way distribution valve 6. Specifically, the first air outlet of the control valve 1 is connected to the limit valve 12 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com