Automatic disinfecting and drying line for suspended penguin package

An automatic disinfection and packaging bag technology, applied in the direction of transportation and packaging, conveyors, etc., can solve the problems of leaving scratches, damage to the anti-theft ring, easy deformation of penguin-shaped packaging bags, etc., to achieve no deformation and scratches, improve Good work efficiency and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

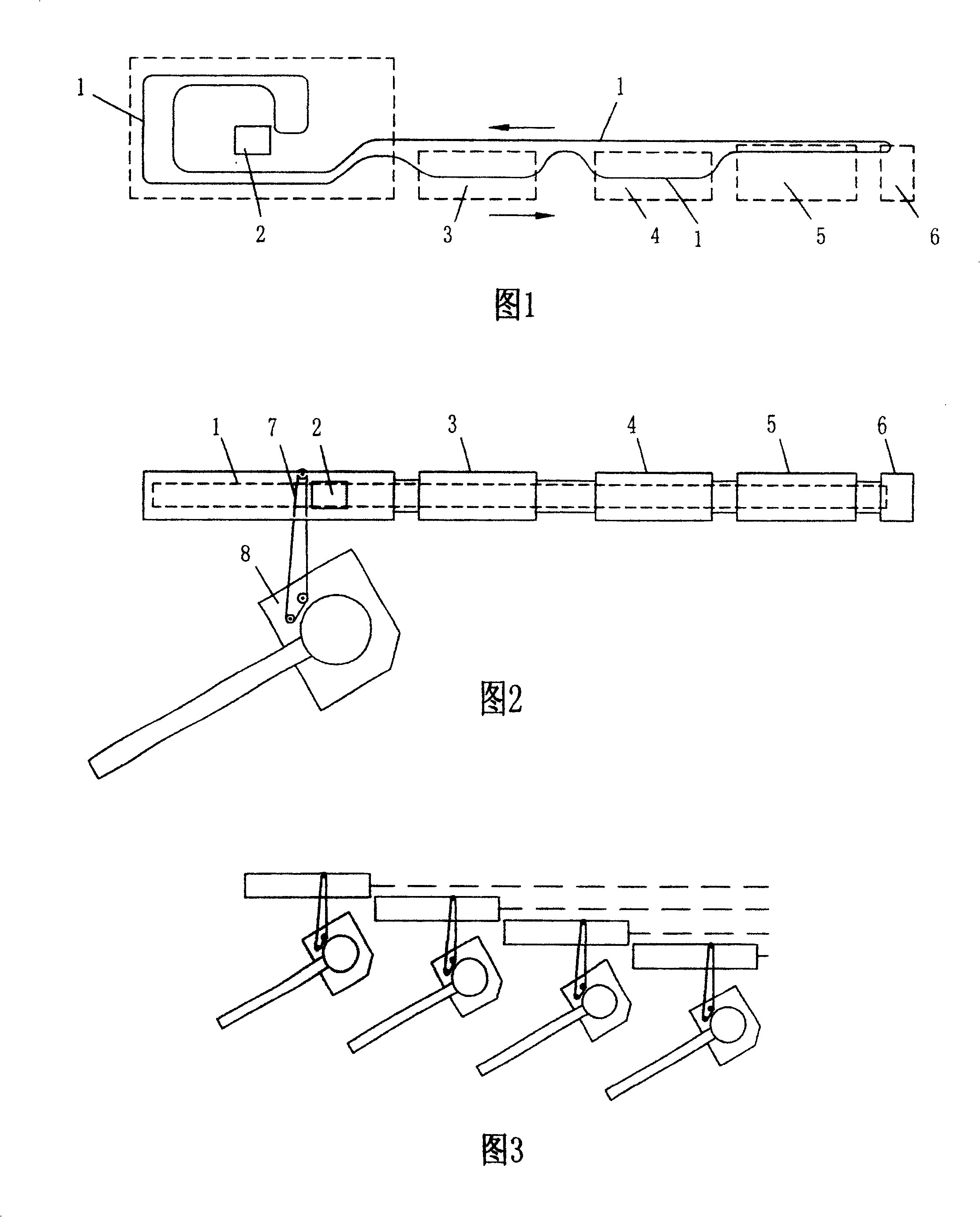

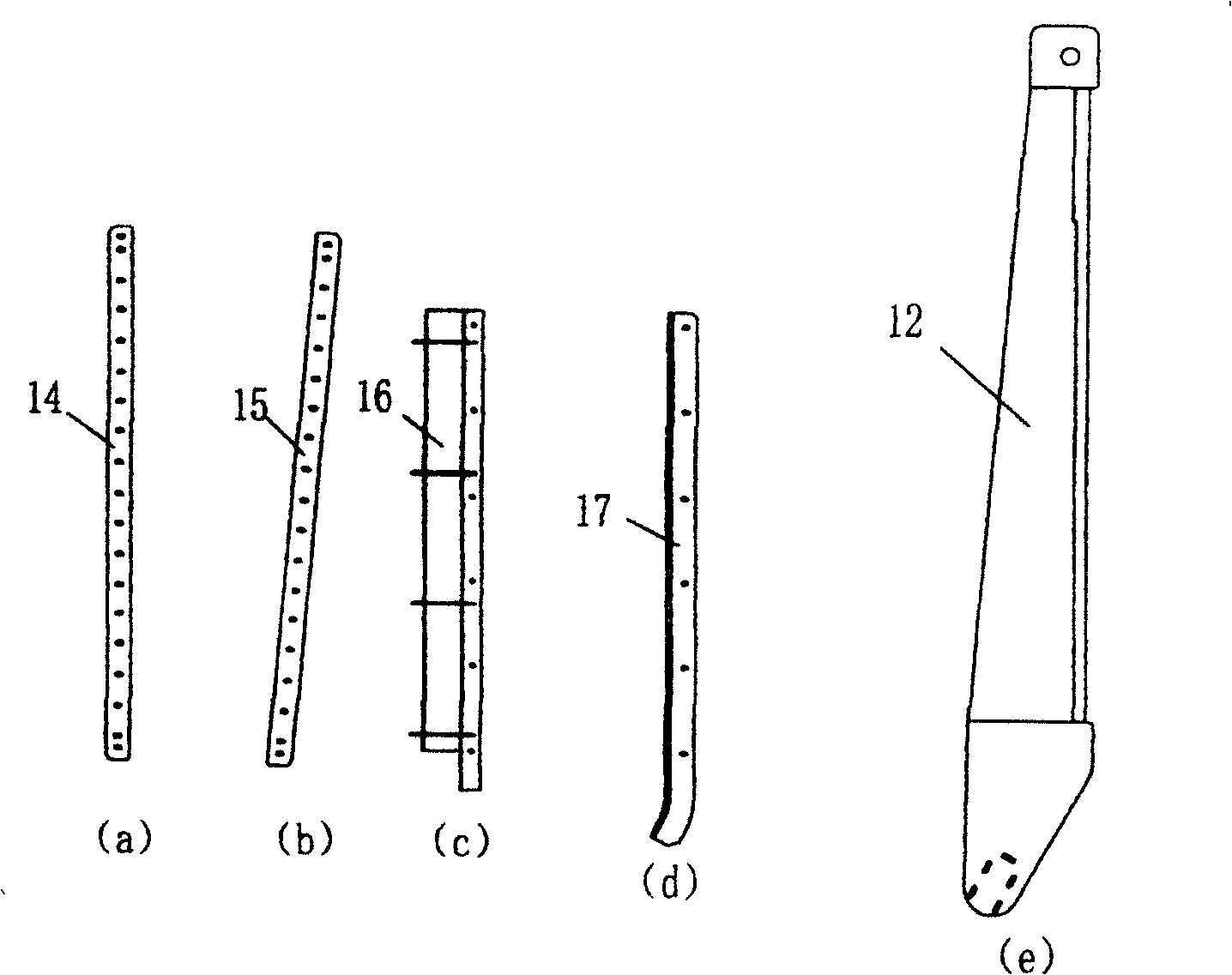

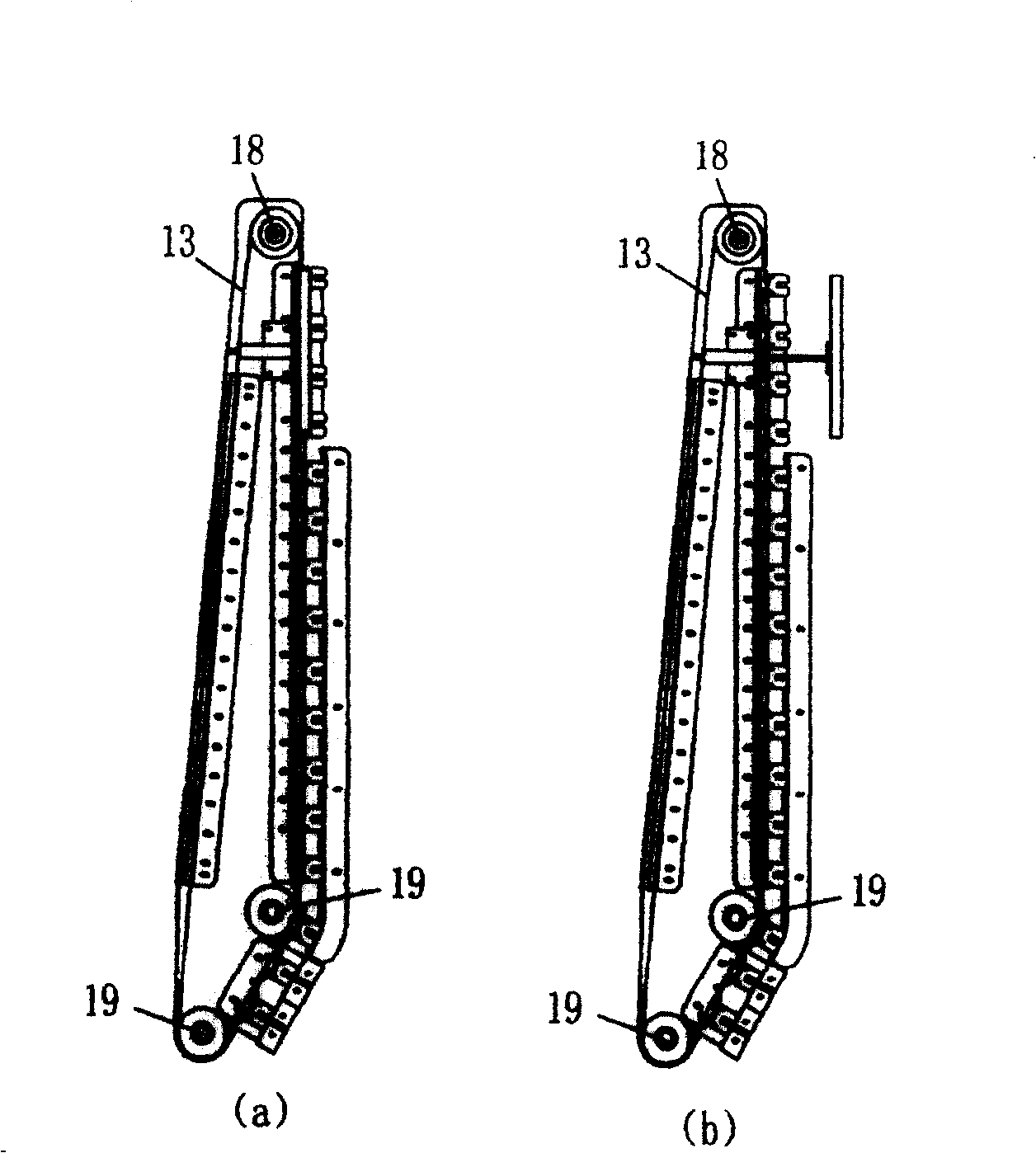

[0056] As shown in Figure 1 and Figure 2, the automatic disinfection and drying line for hanging penguin-shaped packaging bags sequentially includes a filling machine 8, a rotary conveyor chain 7, a feeding machine 2, a disinfection machine 3, a cooling machine 4 and a drying machine along the jelly conveying direction. The drying machine 5 also includes a support, a suspension conveyor chain 1, a driving device 6 and a control system, and a chain guide liner 77 is arranged between the sterilizer 3, the cooling machine 4, and the dryer 5 to support the suspension conveyor chain 1 up and down. Pass through each inlet and outlet to form a loop (such as Figure 17 shown). As shown in Figure 3, multiple hanging penguin-shaped packaging bag automatic disinfection and drying lines can be set side by side and operate at the same time. The feeding machine 2 is set at the input end of the circulation loop, and the jelly is transmitted to the hanging conveyor chain 1, and the conveyor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com