Method for detecting hexavalent chrome in dyed leather and product

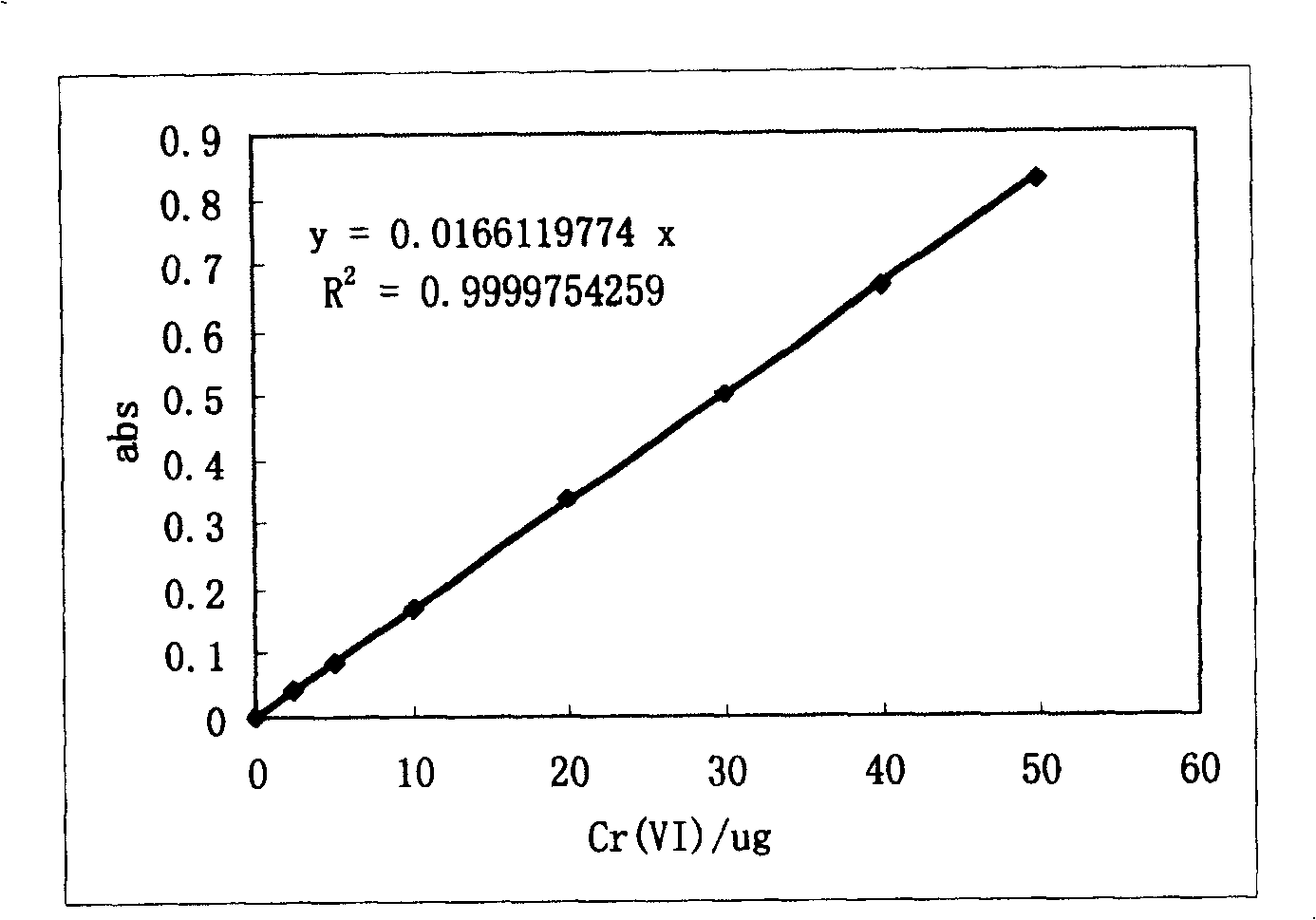

A detection method and technology of hexavalent chromium, which is used in the measurement of color/spectral properties, preparation of samples for testing, etc. problem, to achieve the effect of low cost, high sensitivity and preventing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1.1 Extraction of samples

[0024] Accurately weigh 10 g (accurate to 0.01 g) of the shredded leather sample into a conical flask, add 1 mL of phosphate buffer (pH=9.63, 2 mol / L dipotassium hydrogen phosphate aqueous solution) and 99 mL of water, mix well, After shaking at room temperature for 2 hours, filter with a 0.45 μm filter membrane.

[0025] 1.2 SPE column pretreatment

[0026] Add 4mL sodium citrate saturated solution (chemical modifier) into the graphitized carbon black solid-phase extraction column (abbreviated as SPE), vacuum filter, the vacuum degree does not exceed 20340Pa, when the liquid surface of the remaining sodium citrate saturated solution in the column leaves the When the upper sieve plate is 2-3mm, stop the suction filtration and wait for use.

[0027] 1.3 Decolorization of extract

[0028] Accurately pipette 10 mL of the filtered extract into a 25 mL beaker, add 2 mL of saturated sodium citrate solution, mix well, pour into a solid phase ex...

Embodiment 2

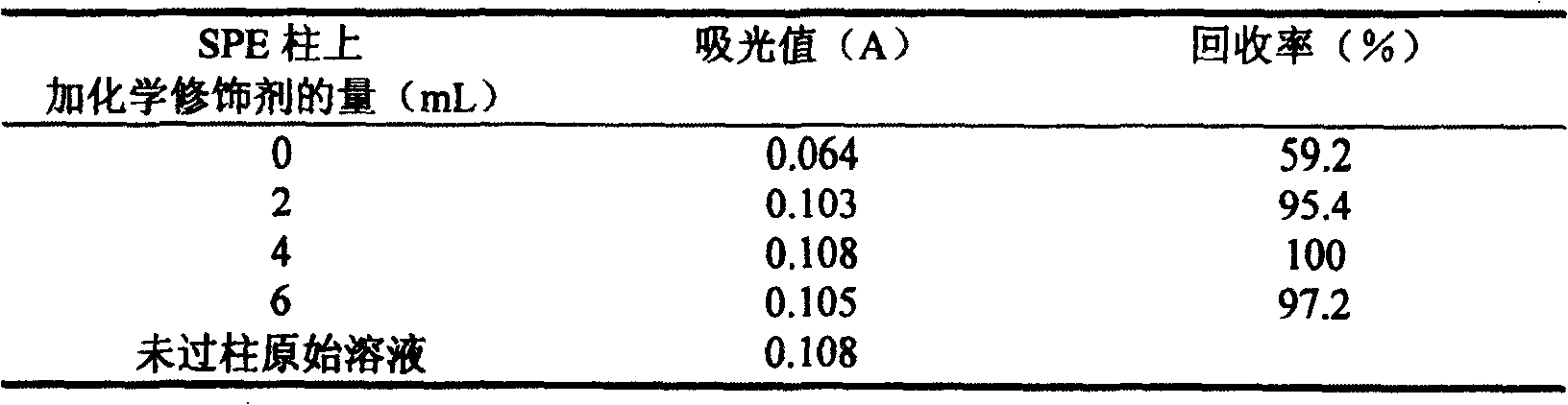

[0047] According to the steps described in Example 1, a detection test was carried out on the extract of an actual leather sample 1# (gray leather). The results are shown in Table 1.

[0048] Using 4mL and 6mL of chemical modifiers to pretreat the graphitized carbon black SPE column, the recoveries can reach 100% and 97.2%, respectively. However, the recovery rate of the graphitized carbon black column pretreated with only 2 mL of chemical modifier is about 95%. It can be seen that no matter for the aqueous solution or the actual leather extract, the graphitized carbon black column is pretreated with 4mL chemical modifier, and the ideal recovery rate can be achieved.

[0049] Table 1 Actual Sample 1# Results

[0050]

Embodiment 3

[0052] Take another actual leather sample 2# (beige leather), according to the steps described in Example 1, add Cr (VI) standard (equivalent to 3mg / kg) in the extract. The graphitized carbon black solid phase extraction column was pretreated with 4mL sodium citrate saturated solution, one part of the extract was directly passed through the column, and the other part was added with 2mL sodium citrate saturated solution and then passed through the column. The recovery results are shown in Table 2.

[0053] Table 2 actual leather sample 2# results

[0054]

[0055] For the actual leather sample 2#, only adding chemical modifier pretreatment on the graphitized carbon black solid phase extraction column can not prevent the adsorption loss of Cr(VI) well during the filtration process, and at the same time add 2mL chemical modification to the extract The recovery rate can be increased from the original 86.4% to 95.1%, and a good recovery result has been obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com