Turpentine liquid purifying pan and its technical process

The technology of rosin resin and purification pot is applied in the field of rosin processing, which can solve the problems of ineffective washing of equipment, large and complicated equipment, etc., and achieve the effect of simple structure and good decolorization and purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

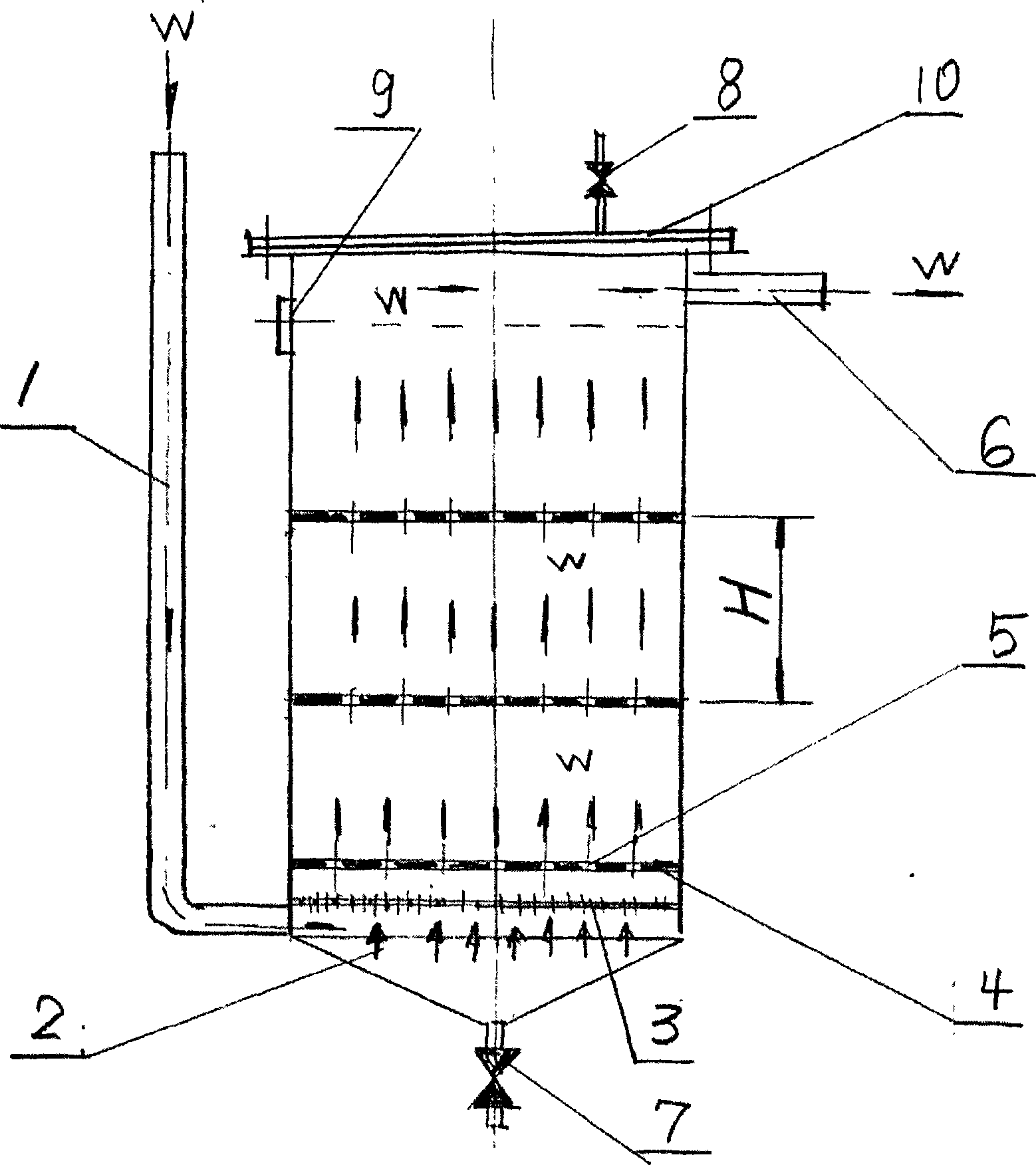

[0018] Referring to the accompanying drawings, the turpentine fat liquid purification pot of the present invention comprises a pot body 2, a slagging valve 7 is arranged at the bottom of the pot body 2, and a fat liquid input pipe 1 is connected to the bottom side of the pot body 2, and the fat liquid input pipe 1 is connected to the bottom of the pot body 2. 1 Install a scum filter 3 in the pot body 2 above the connection port, and install 2 diverter plates 4 in the pot body above the scum filter 3. The distance H between each diverter plate is 500 mm-1000 mm. Distributor holes 5 with a diameter of 3 mm to 8 mm are evenly distributed in the plate 4, and the distance between the holes is 5-6 times the diameter of the hole; The fat liquid output pipe 6 has a pot cover 10 on the top of the pot body 2, and on the pot cover 10, there is a water inlet pipe leading into the pot body, and the water inlet pipe is connected with the water inlet control valve 8.

[0019] Carry out the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com