Selective micro processing method and system for near field optic virtual light probe

A near-field optics and virtual light technology, applied in the fields of laser micromachining and near-field optics, can solve the problems of difficult spacing control, complex system, weak selectivity, etc. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

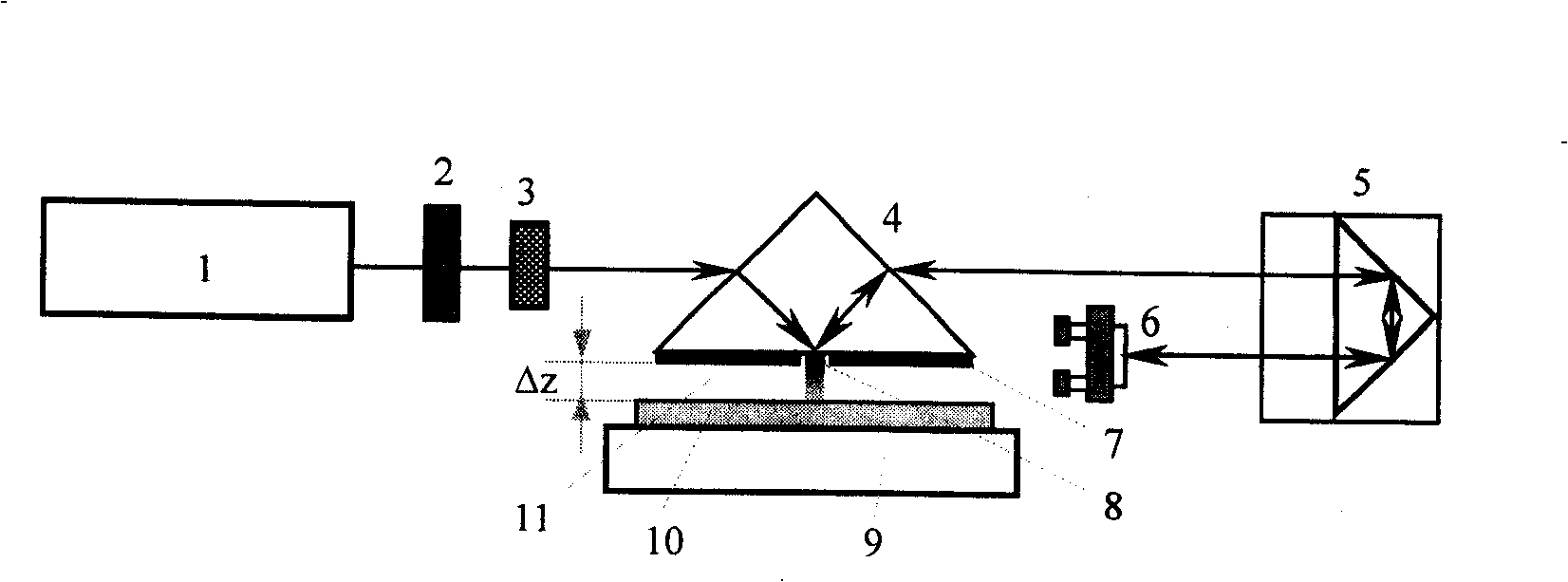

[0015] to combine figure 1 The schematic diagram of the near-field optical virtual light probe selective micromachining system of the example is described as follows for the details and implementation of the specific device of the present invention:

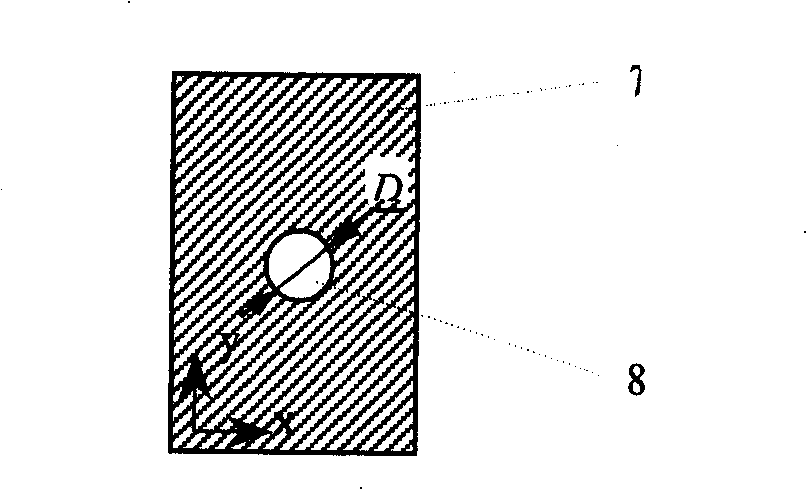

[0016] The basic device for selective micromachining of near-field optical virtual optical probes is composed of a laser 1, an external optical system, and a micromachining system. Composed of polarizer 3, optical retarder 5, and mirror 6; the micromachining system includes near-field optical virtual light probe formation and adjustment system, processing material control system, and the main components include triangular prism 4, metal film layer 7, micro-movement Stage 9 and processing material 10.

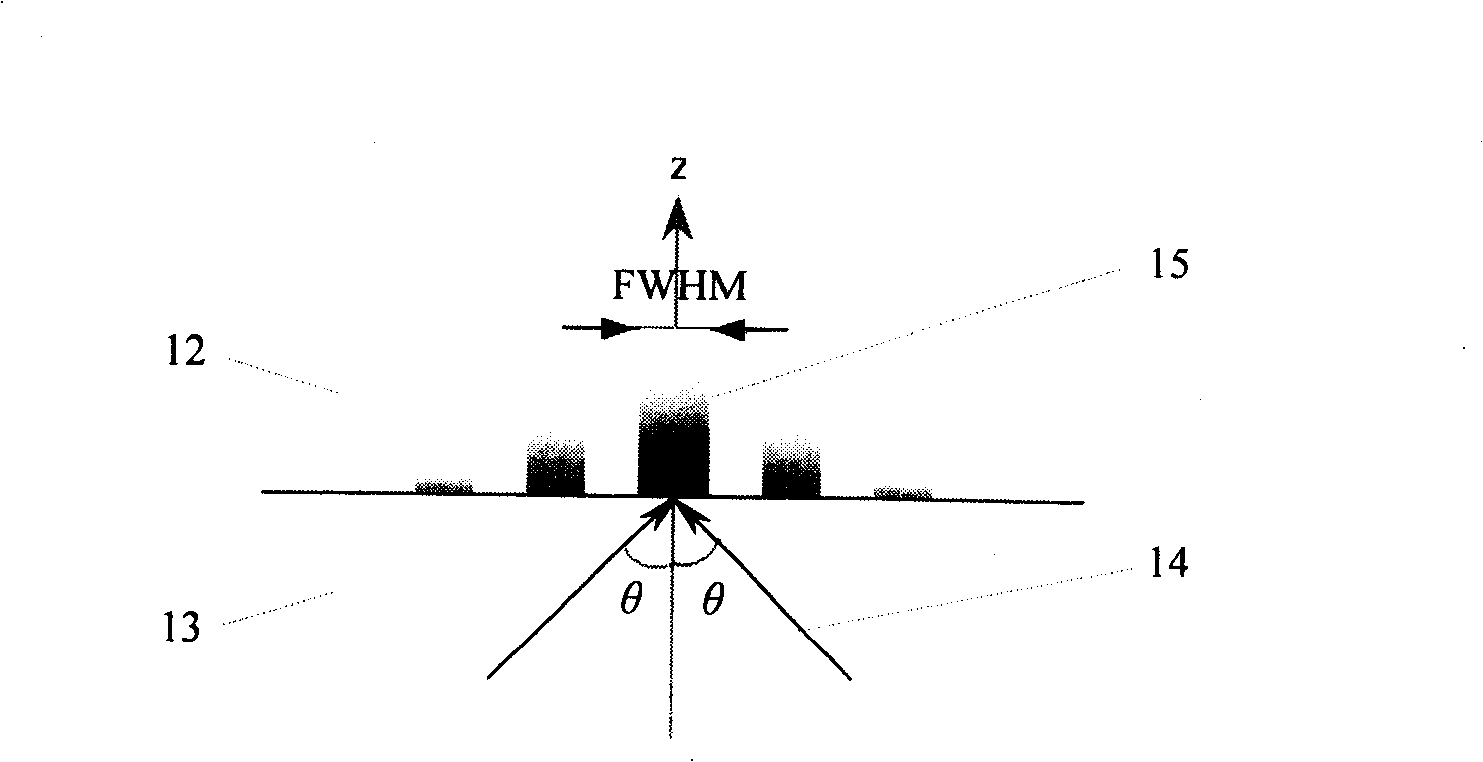

[0017] The core part of the system proposed by the present invention is a near-field optical virtual light probe forming and adjusting system. In order to generate the evanescent wave field at the interface between the triangular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com