Manufacturing method of iron-nickel alloy bag oxygen-free copper low-resistance packaging lead wire

A technology of iron-nickel alloy and manufacturing method, which is applied in the field of manufacturing iron-nickel alloy-coated oxygen-free copper low-resistance packaging leads, and can solve problems such as poor thermal conductivity, inability to achieve hermetic sealing, and high air leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

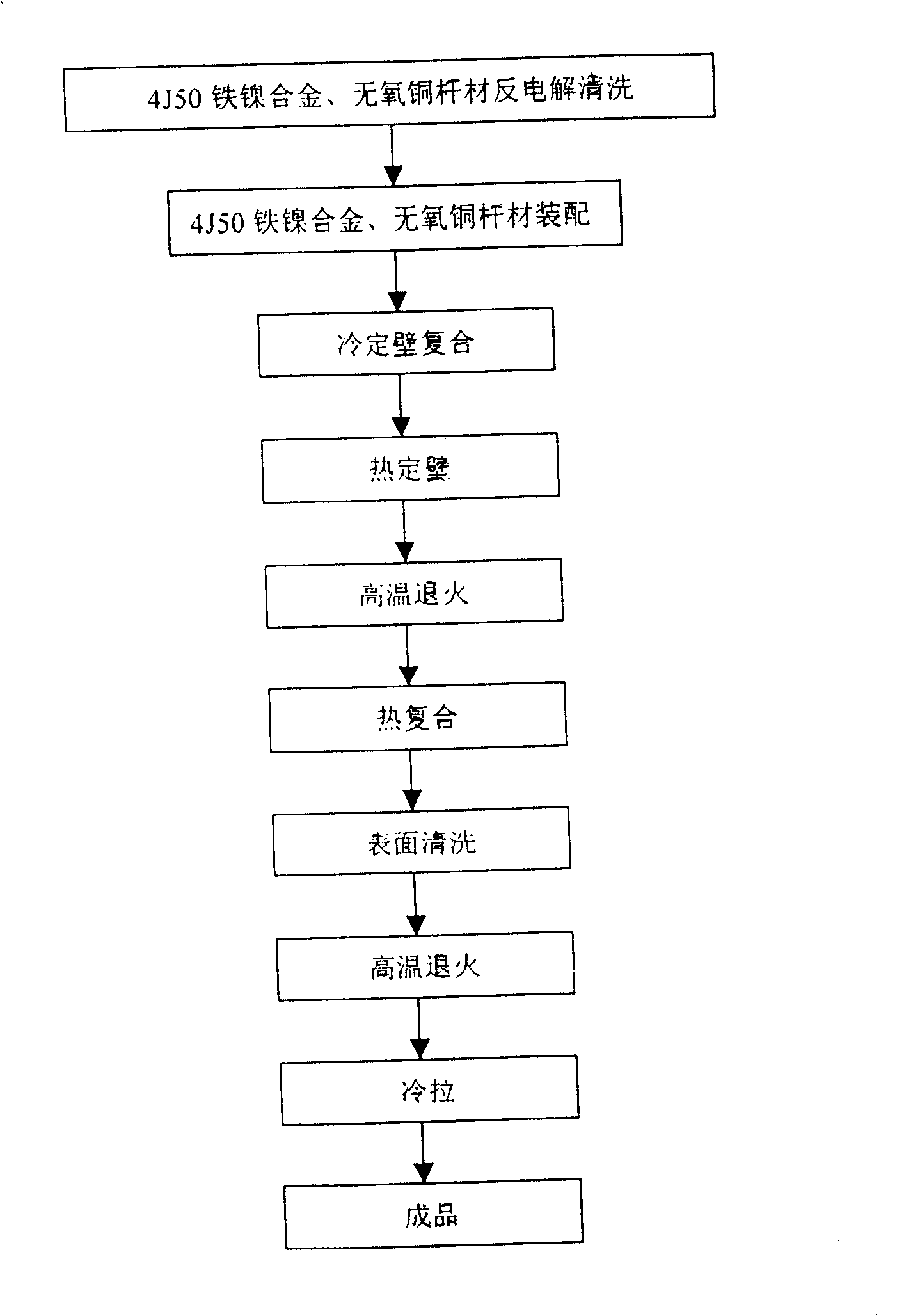

[0013] according to figure 1 As shown, the selected mass ratio is Fe 50 Ni 50 The 4J50 iron-nickel alloy round tube with a diameter of 12mm and a wall thickness of 3mm, and an oxygen-free copper rod with a diameter of 5mm are reversely electrolytically cleaned to get a fresh surface and then dried, and the oxygen-free copper rod is nested into the A coaxial cladding structure is formed in the iron-nickel alloy round tube to obtain a composite billet. Since the diameter of the oxygen-free copper rod embedded is smaller than that of the iron-nickel alloy round tube, a certain gap is left between the two. The physical properties of the selected iron-nickel alloy round tube and oxygen-free copper rod are shown in Table 1.

[0014] Table I:

[0015] Density (g / cm 3 )

Melting point (W / m.K)

Thermal conductivity

(Ω.mm 2 / m)

Resistivity

(Ω.mm 2 / m)

Thermal expansion coefficient

(10 -6 °C)

Elastic Modulus

(Gpa) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com