Sewing machine with dust collector

A vacuum device and sewing machine technology, which is applied in the field of sewing machines, can solve problems such as the trouble of blowing air into the hand-held spray gun, the deterioration of the working environment, and cumbersome cleaning operations, etc., so as to improve the self-cleaning performance, improve the self-cleaning performance, and prevent poor sewing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

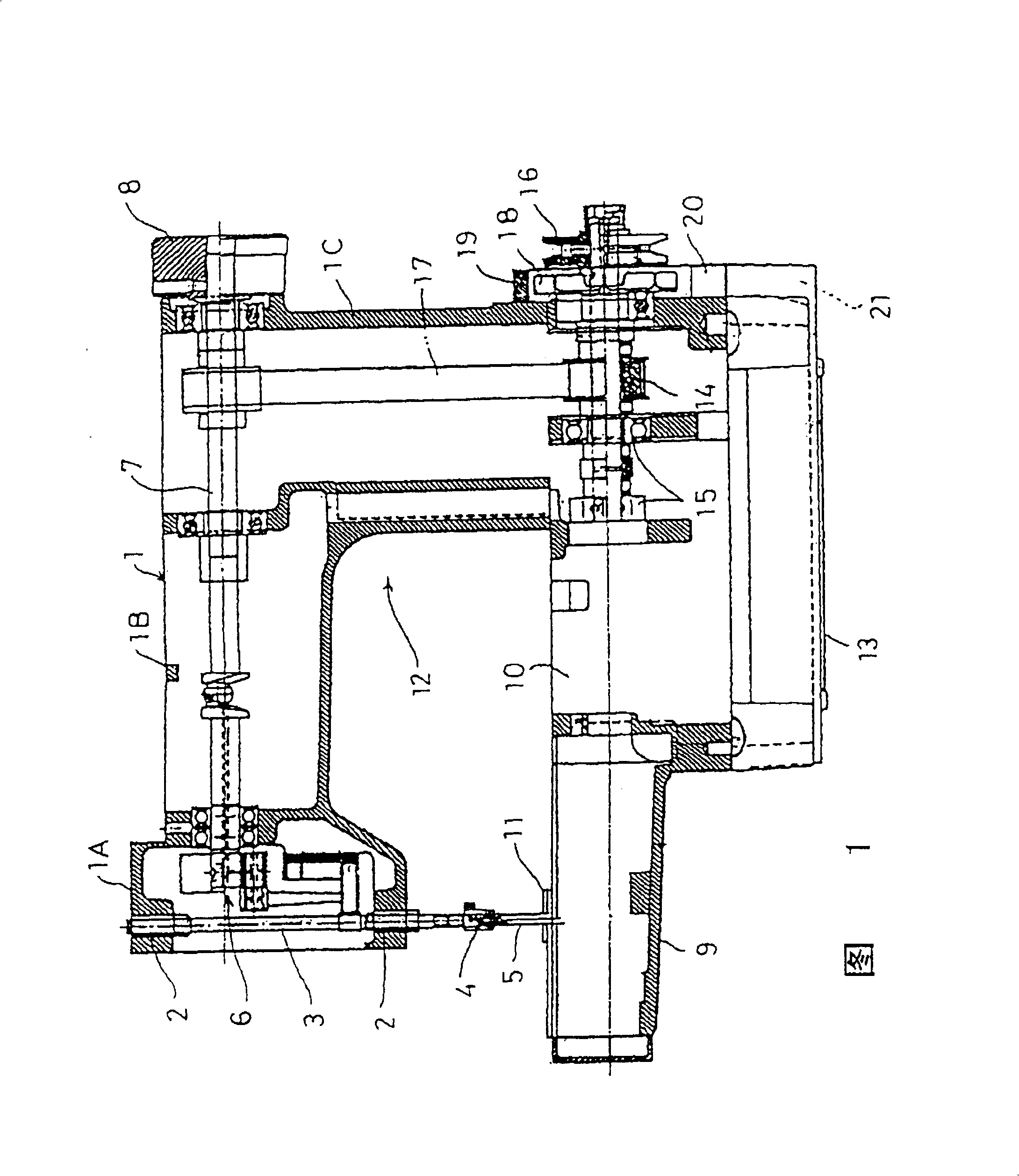

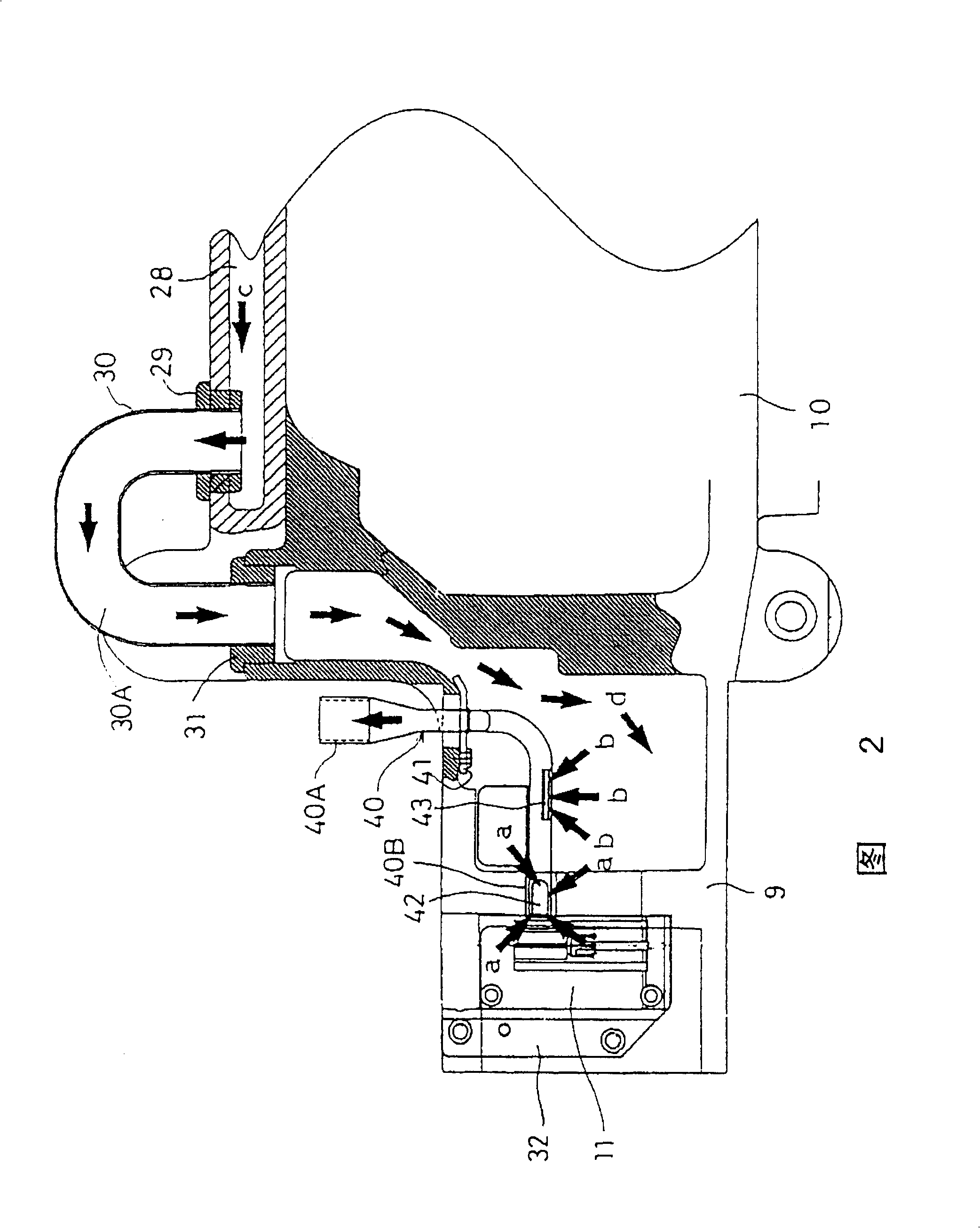

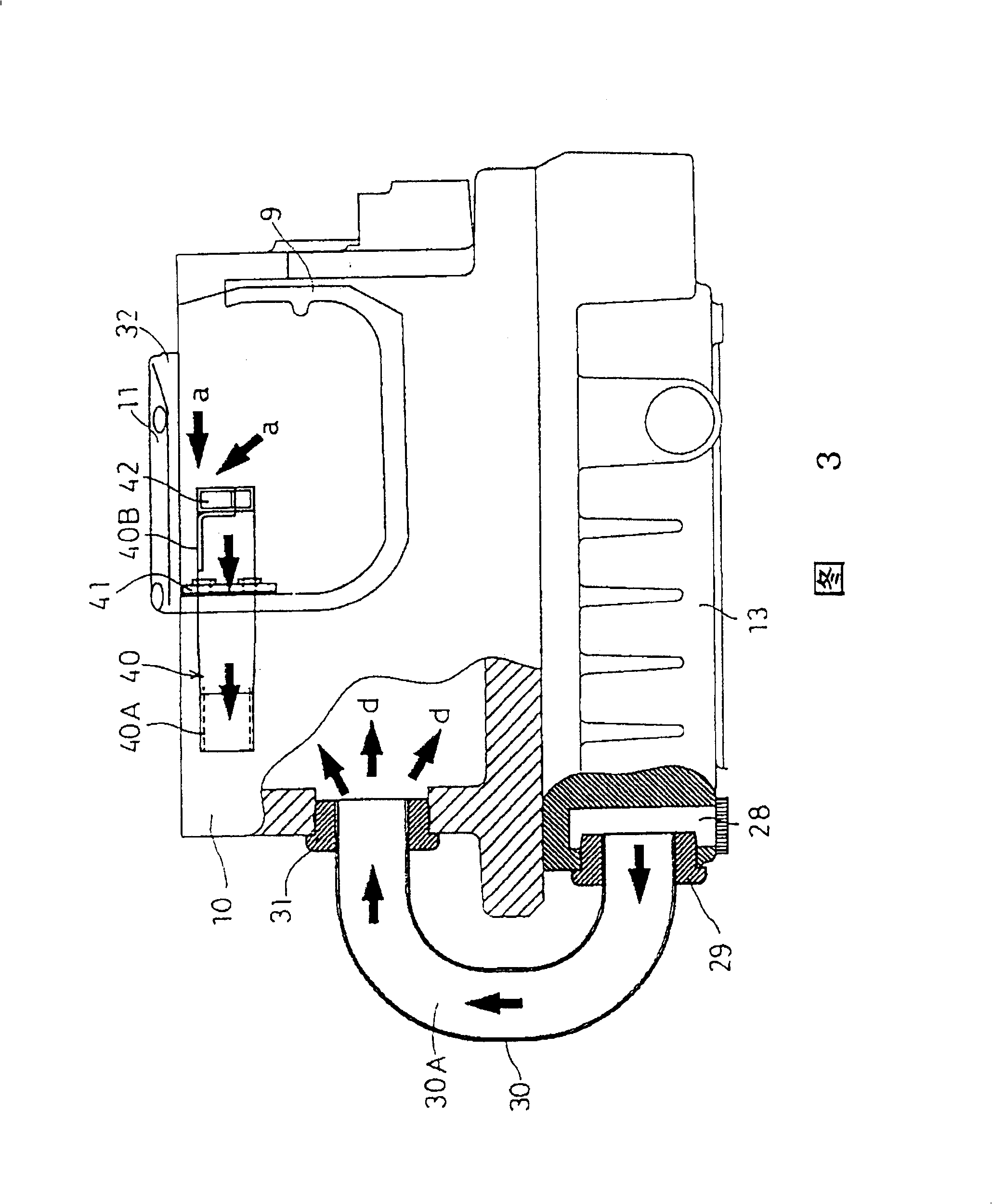

[0020] Embodiments of the present invention described in claims 1-4 are described below with reference to the accompanying drawings.

[0021] Fig. 1 is a partially cutaway front view of a cylindrical base type multi-needle flat sewing machine with a dust suction device according to the present invention. In this figure, 1 is the arm of the sewing machine, and the needle bar 3 is supported on the front end 1A of the needle bar 3 through the bearing 2 so that it can reciprocate in the up and down direction. department. In addition, the upper shaft 7 for driving is also supported through, and the upper shaft 7 for driving can make the needle bar 3 reciprocate up and down through the known needle bar driving mechanism 6 provided in the above-mentioned front end portion 1A. A handwheel 8 is fixed to the protruding end on the right side of the upper shaft 7 .

[0022] 9 is a cylindrical sewing machine base portion, which is integrally fixed to the sewing machine base base portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com