Motor centrally axle coupling structure

A center shaft and pivot joint technology, applied in the field of motor center shaft pivot joint structure, can solve problems such as loosening and falling, motor rotation noise, rotor deflection, etc., to achieve the effect of avoiding loosening and falling, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

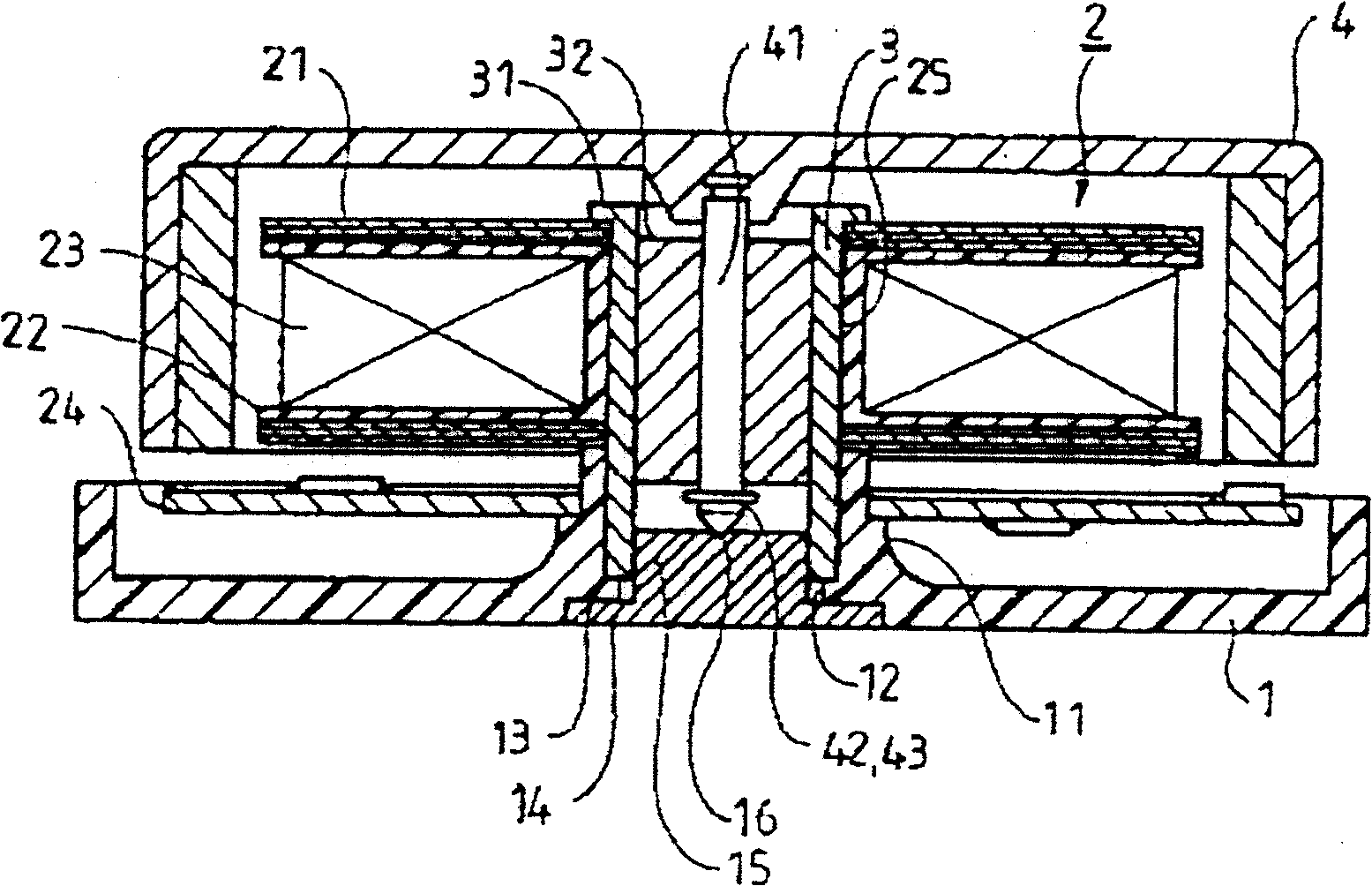

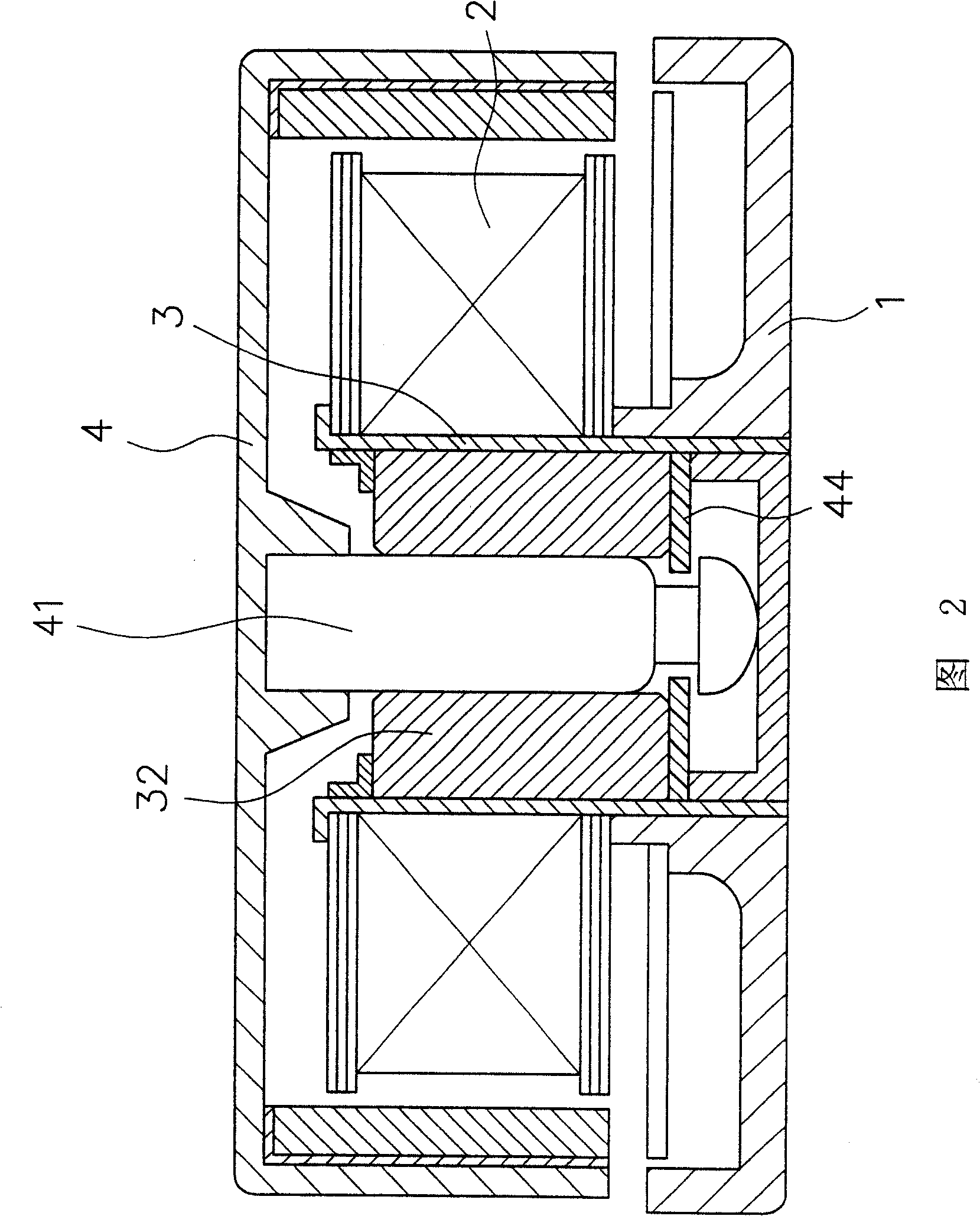

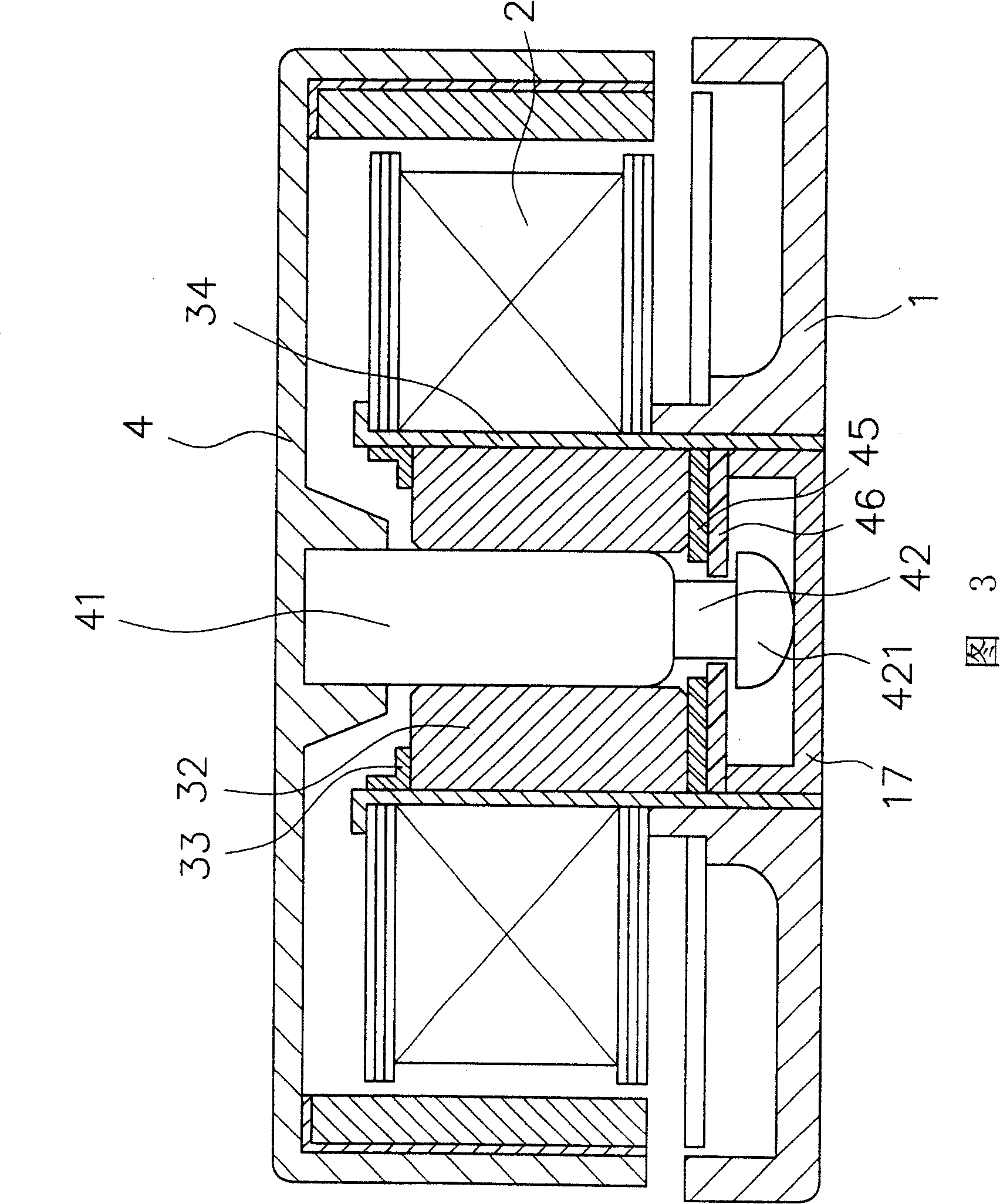

[0026] In order to describe the structure and characteristics of the present invention in detail, several preferred embodiments are listed below and the relative positions of the various components of the present invention are illustrated with reference to the accompanying drawings.

[0027] As shown in Figure 3, the motor is equipped with a shaft tube 34 on a shell base 1. The shaft tube 34 can be integrally formed by the shell base 1, or can be combined and fixed on the shell base 1, and the outer circumference of the shaft tube 34 is sleeved with the stator base. 2. There is a bearing 32 inside, the central shaft 41 of the rotor 4 can be rotated in the center of the bearing 32, and one end of the central shaft 41 is the top 421, and the end side near the top 421 has a ring groove 42 with a smaller outer diameter .

[0028] The bearing 32 is fixed at a predetermined position by the positioning ring 33 above it and the center cover 17 below it, and at least two snap rings are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com