Automatic lacquer spraying system for surface of rotating body

An automatic painting and outer surface technology, applied to the surface coating liquid device, spraying device, coating, etc., can solve the difficulty of controlling the uniformity and thickness of the sprayed paint layer, the impact on production efficiency and product quality, and the inability to achieve different Problems such as fast switching of paint, etc., to achieve the effect of high degree of automation, quality improvement, and fast switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

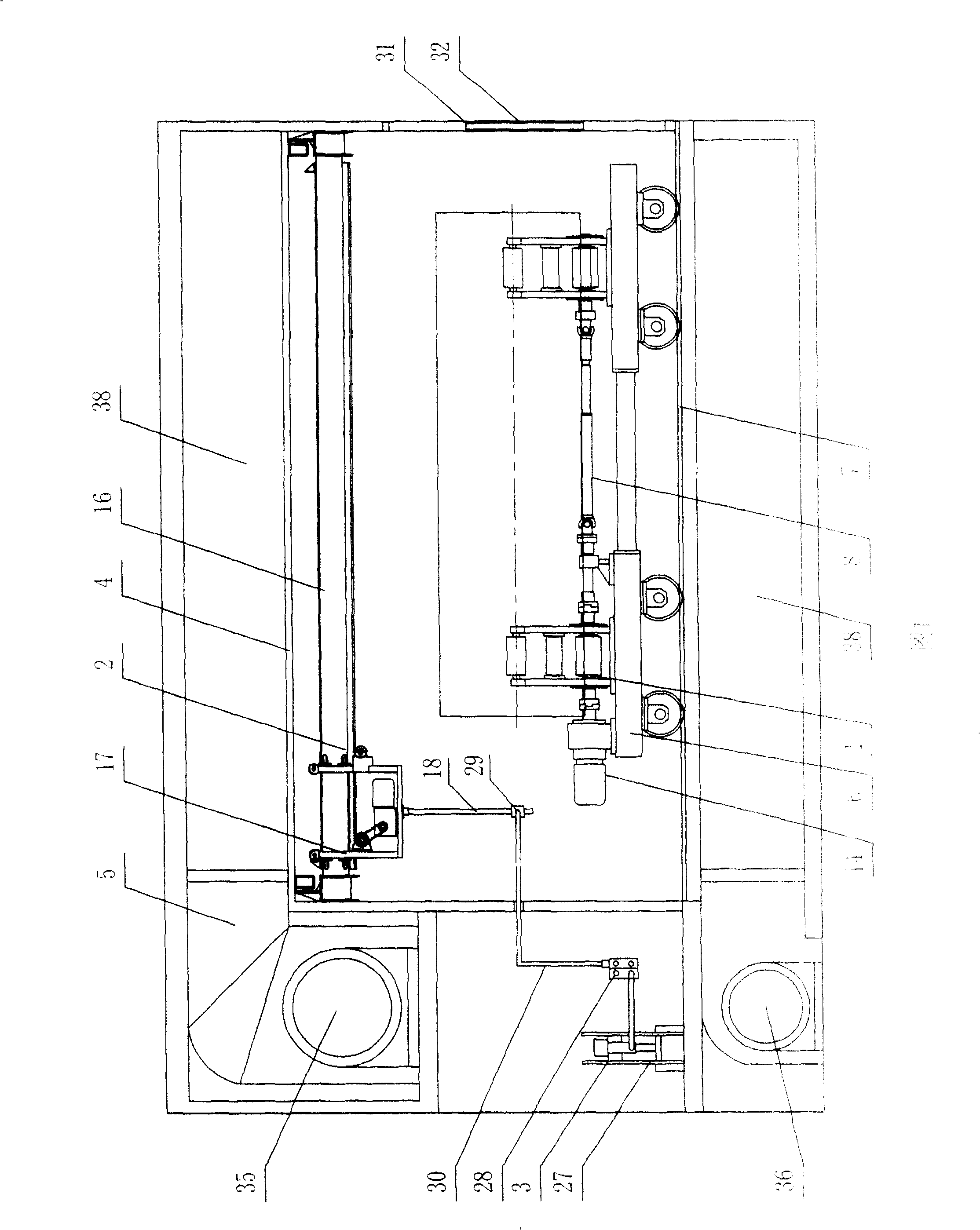

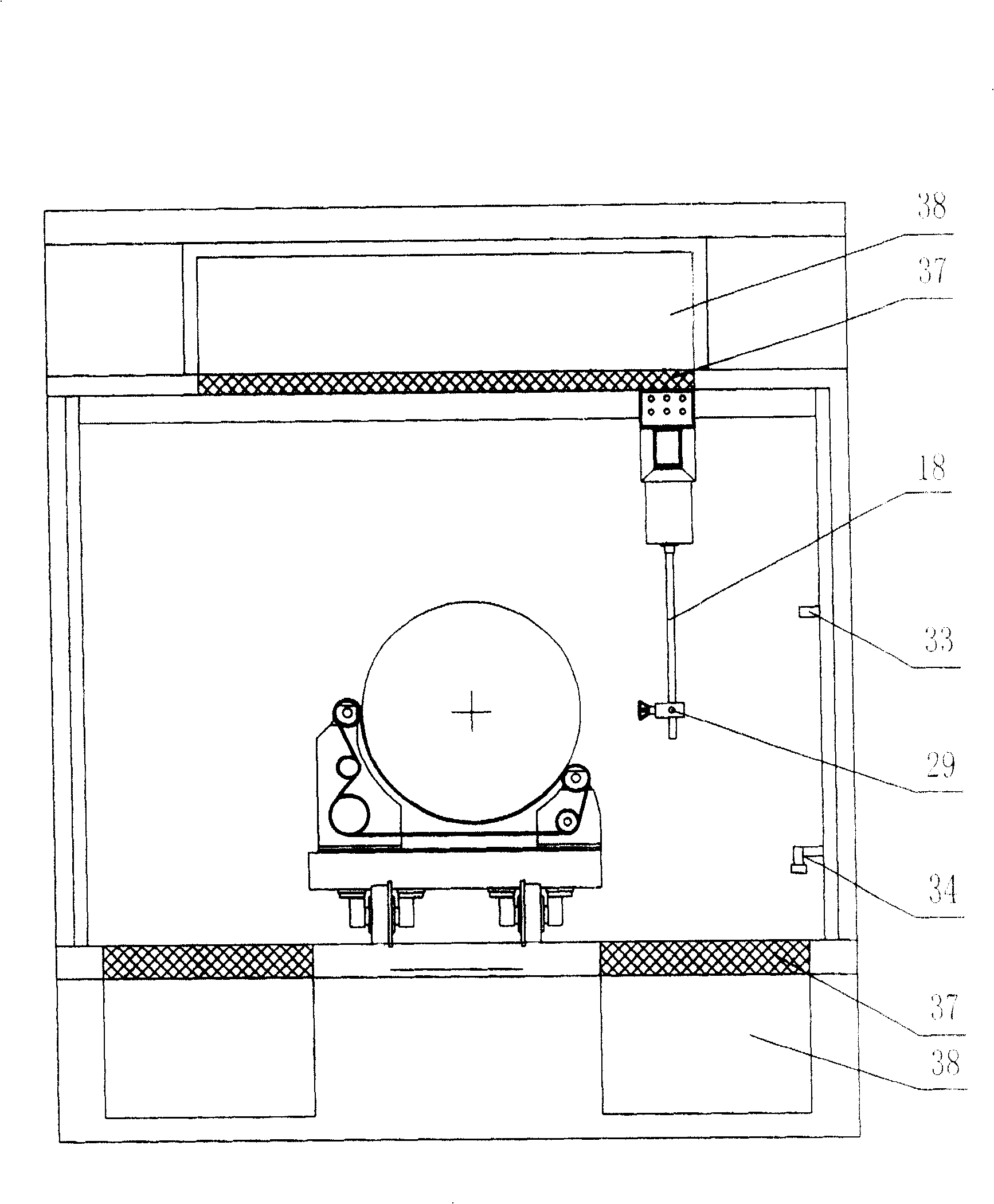

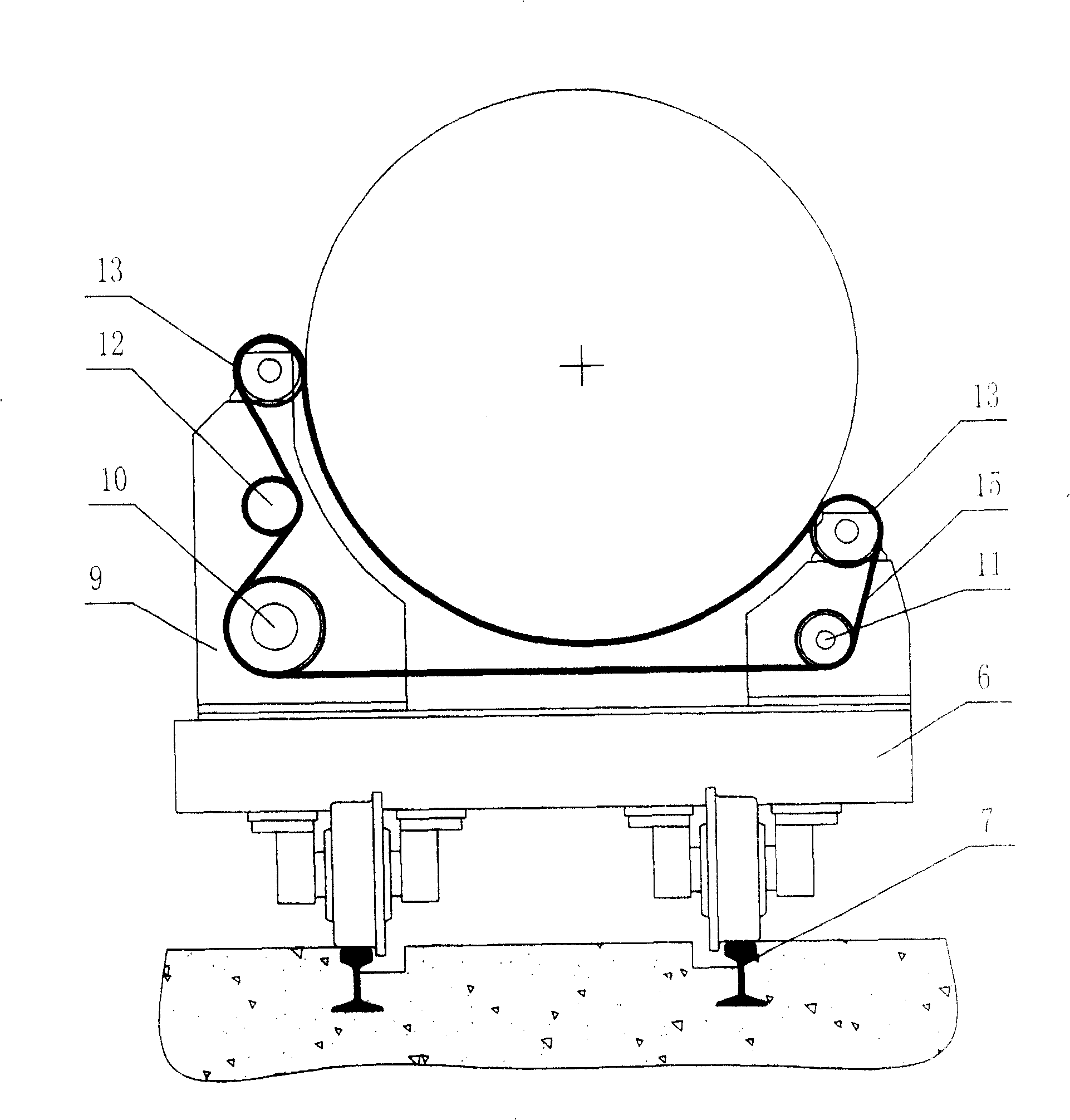

[0016] It includes a paint spraying room 4 with a rectangular ground. The paint spraying room is a closed room with a door 31 at the end and an observation window 32 on the door. A micro-pressure detector 33 and a combustible gas alarm 34 are installed in the paint spraying room 4. It is used to detect the pressure and the concentration of combustible gas in the spray booth. The ground of the spray booth is equipped with a load-carrying vehicle 6, which is placed on a horizontal track 7, and a supporting and rotating device 1 is arranged on the supporting vehicle, and the supporting and rotating device includes roller frames 9 installed at both ends of the supporting vehicle frame. , two spaced rollers 13 are installed on the roller frame, and the rollers are connected with the driving device through the synchronous toothed belt 15, and the driving devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com