Paint spraying device for glass product decoration

A technology for glass products and components, which is applied to spray devices, paint booths, etc., can solve the problems of high cost, difficult adjustment, and large labor of the numerical control system, and achieve the effects of improving spraying efficiency, convenient operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

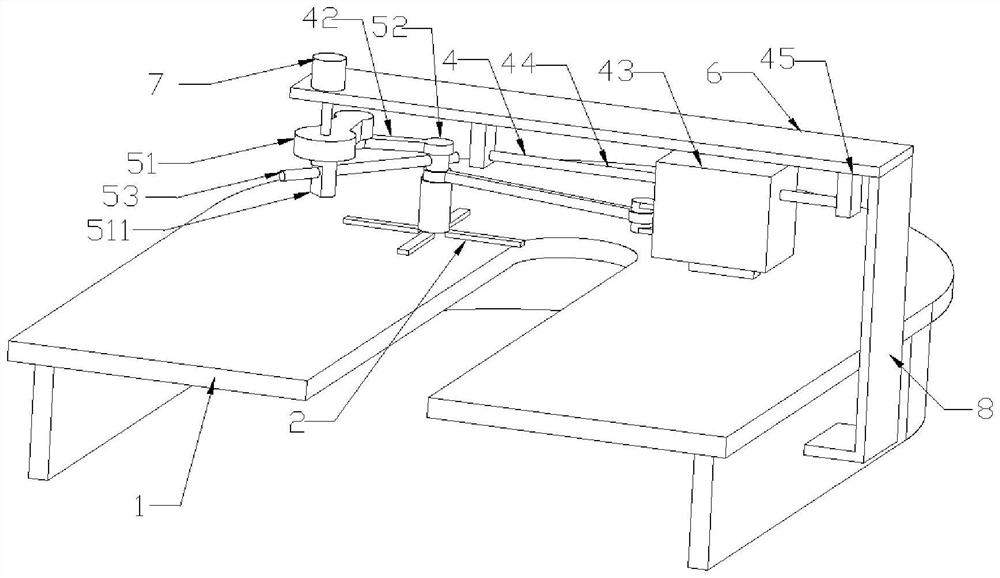

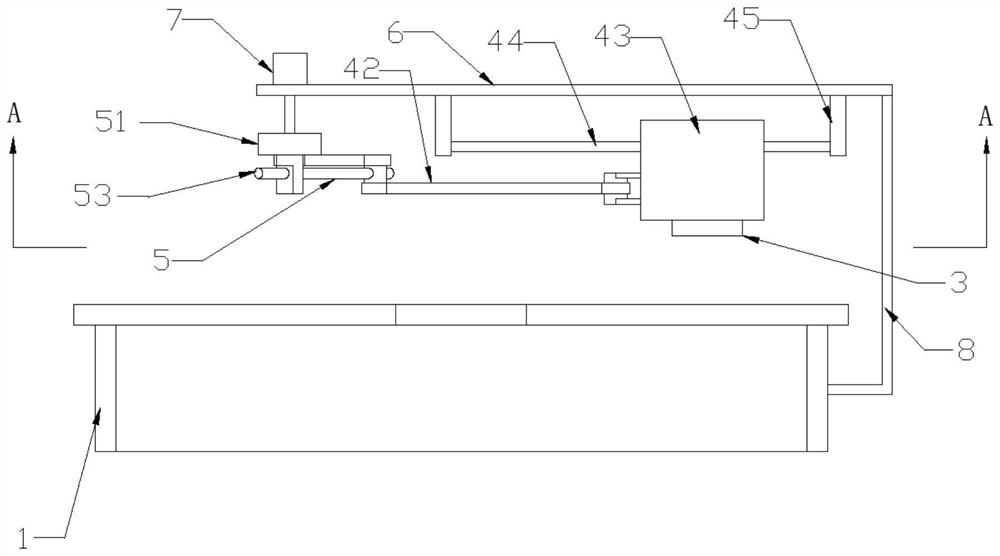

[0029] A paint spraying device for decoration of glass products, comprising a paint spraying assembly 3, a U-shaped conveyor belt mechanism 1, a fan assembly 2, a driving mechanism 4 and an adjusting mechanism 5;

[0030] The paint spraying assembly 3 can reciprocate horizontally above one end of the U-shaped conveyor belt mechanism 1 under the drive of the driving mechanism 4, and reciprocately spray the glass products on the U-shaped conveyor belt mechanism 1;

[0031] The driving mechanism 4 can change the stroke of the horizontal reciprocating movement of the paint spraying component 3 under the driving of the adjusting mechanism 5, so as to adapt to spraying glass products of different sizes.

[0032] The fan assembly 2 is driven by the drive mechanism 4 to make a circular motion above the other end of the U-shaped conveyor belt mechanism 1. The conveyor belt feeding direction in the U-shaped conveyor belt mechanism 1 is from the bottom of the paint spraying assembly 3 to ...

Embodiment 2

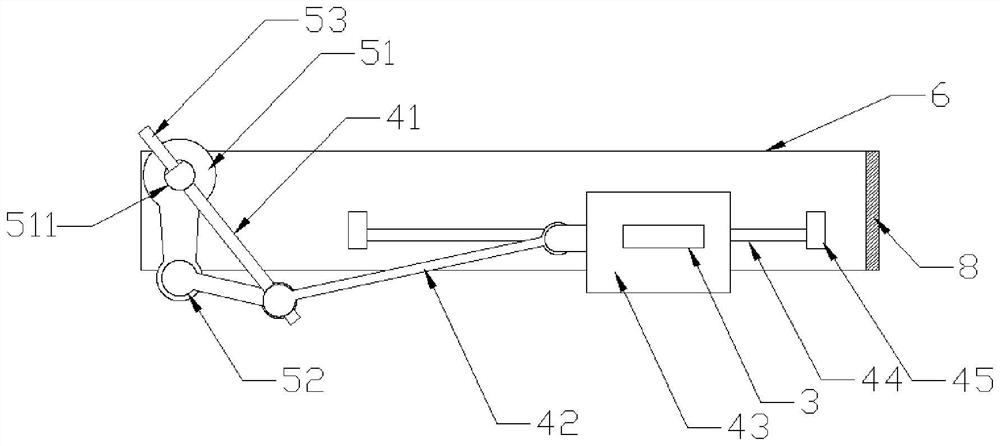

[0034] On the basis of the first embodiment, in order to realize the function of horizontal reciprocating painting, the driving mechanism 4 used in the painting device for decoration of glass products includes a driving rod 41, a driven rod 42 and a sliding block 43;

[0035] One end of the driving rod 41 is rotatably arranged above the other end of the U-shaped conveyor mechanism 1, and the other end of the driving rod 41 is hinged with one end of the driven rod 42; the other end of the driven rod 42 is hinged with the slider 43; the slider 43 can move horizontally It is arranged above one end of the U-shaped conveyor belt mechanism 1, and the paint spraying assembly 3 is installed under the slider 43. One end of the driving rod 41 rotates, and the other end drives the slider 43 to move horizontally and reciprocatingly through the driven rod 42, similar to the mechanism of the crank slider 43. , so as to realize the reciprocating movement of the paint spraying assembly 3 .

Embodiment 3

[0037] On the basis of the second embodiment, in order to realize the function of mechanically adjusting the stroke of the reciprocating movement of the paint spraying assembly 3, the paint spraying device for glass product decoration further comprises a support plate 6; the connecting plate 8 is vertically installed on the bracket under the U-shaped conveyor mechanism 1 On the upper side, the support plate 6 is installed on the connecting plate 8, the support plate 6 is horizontally arranged above the U-shaped conveyor belt mechanism 1, the bottom ends of the support plate 6 are provided with supports 45, and a guide rod is installed horizontally between the two supports 45. 44. The slider 43 is sleeved on the guide rod 44 and can move along the guide rod 44;

[0038] The adjusting mechanism 5 includes a first connecting rod 51, a second connecting rod 52 and an adjusting rod 53;

[0039] One end of the first connecting rod 51 is rotatably arranged on the lower end face of on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com