Printing circuit board

A technology for printed circuit boards and circuit layers, which is applied to printed circuit components, secondary processing of printed circuits, and printed electrical components, etc. It can solve problems such as electrical defects and achieve the effect of maintaining electrical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

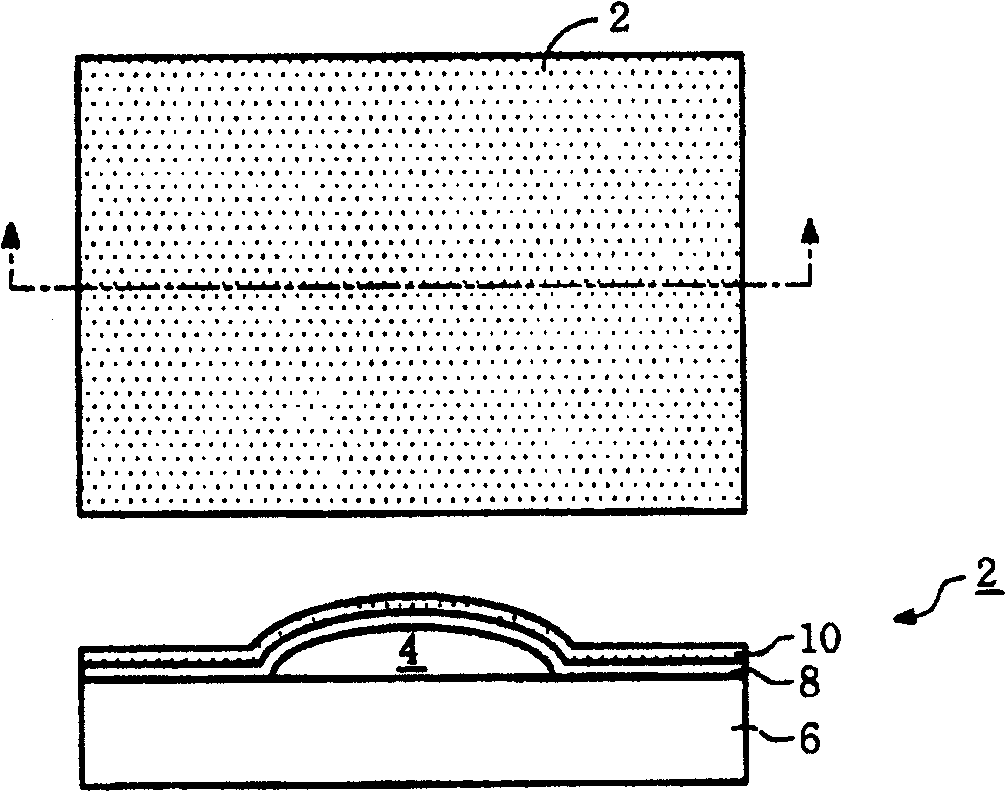

[0019] The invention relates to a printed circuit board (PCB). The source of the idea is that it can avoid air bubbles in the copper foil layer when the lead-free solder paste is used for surface mounting (SMT) in the manufacture of the board of the optical drive. , this printed circuit board is the substrate required for the board in the optical drive.

[0020] At present, the printed circuit board of the machine board used in the optical drive is provided with a layer of substrate and a circuit layer on the upper and lower surfaces respectively. The circuit layer is a conductive material, and copper foil is commonly used as the circuit layer, and the substrate is mostly FR1 substrate, CEM1 substrate, or CEM3 substrate. In this embodiment, copper foil will be used as the circuit layer, that is, the copper foil layer described below, to illustrate the relevant technical features of the present invention.

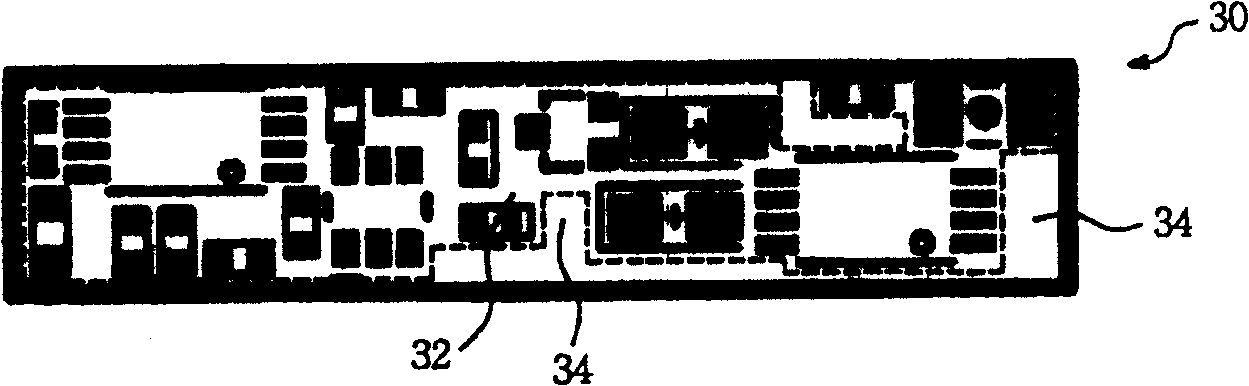

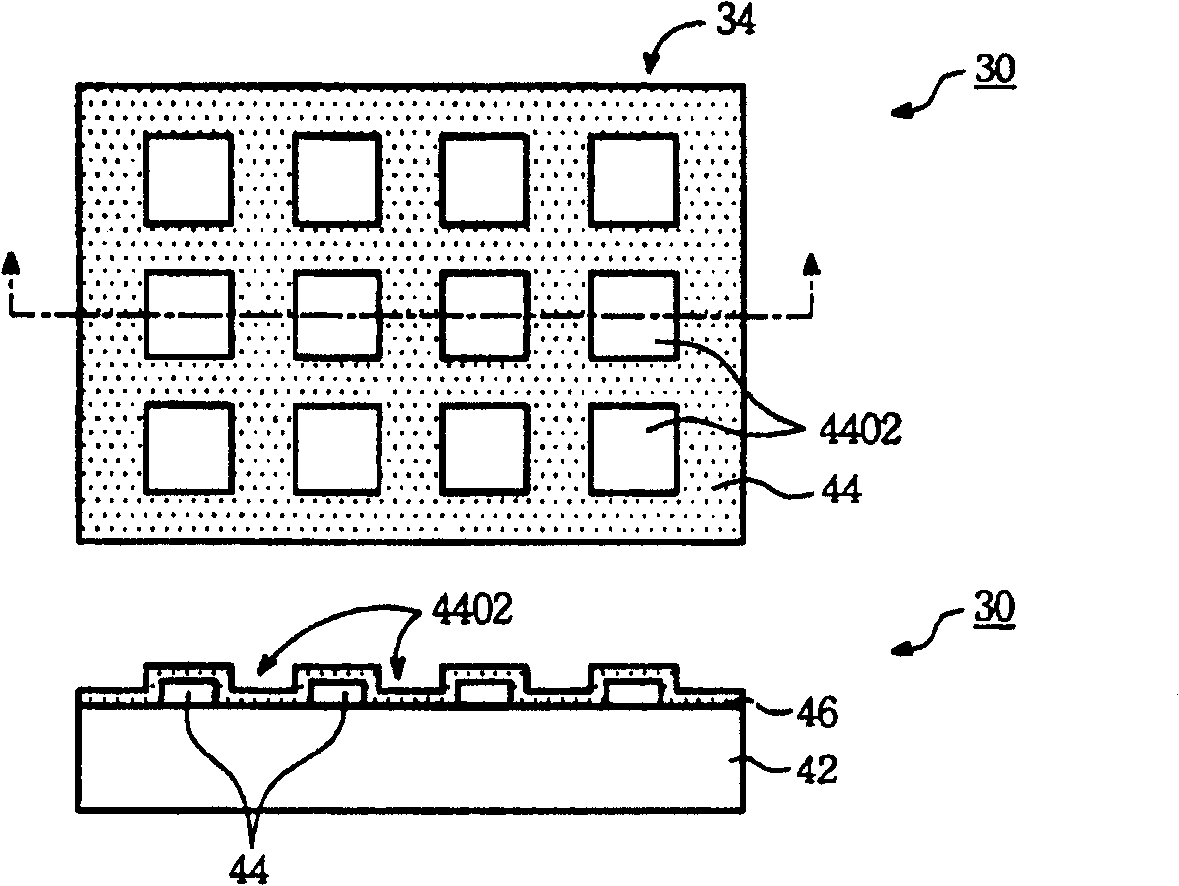

[0021] Such as figure 2 , figure 2 is a schematic diagram of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com