Multiple drums mechanism for eliminating ash through slight shock in dust catcher, and method of slight shock

A technology of cleaning mechanism and dust collector, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve the problems of high manufacturing cost, affecting the working environment, easy to produce deviation, etc., so as to reduce production costs and solve the The effect of complex structure and novel structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

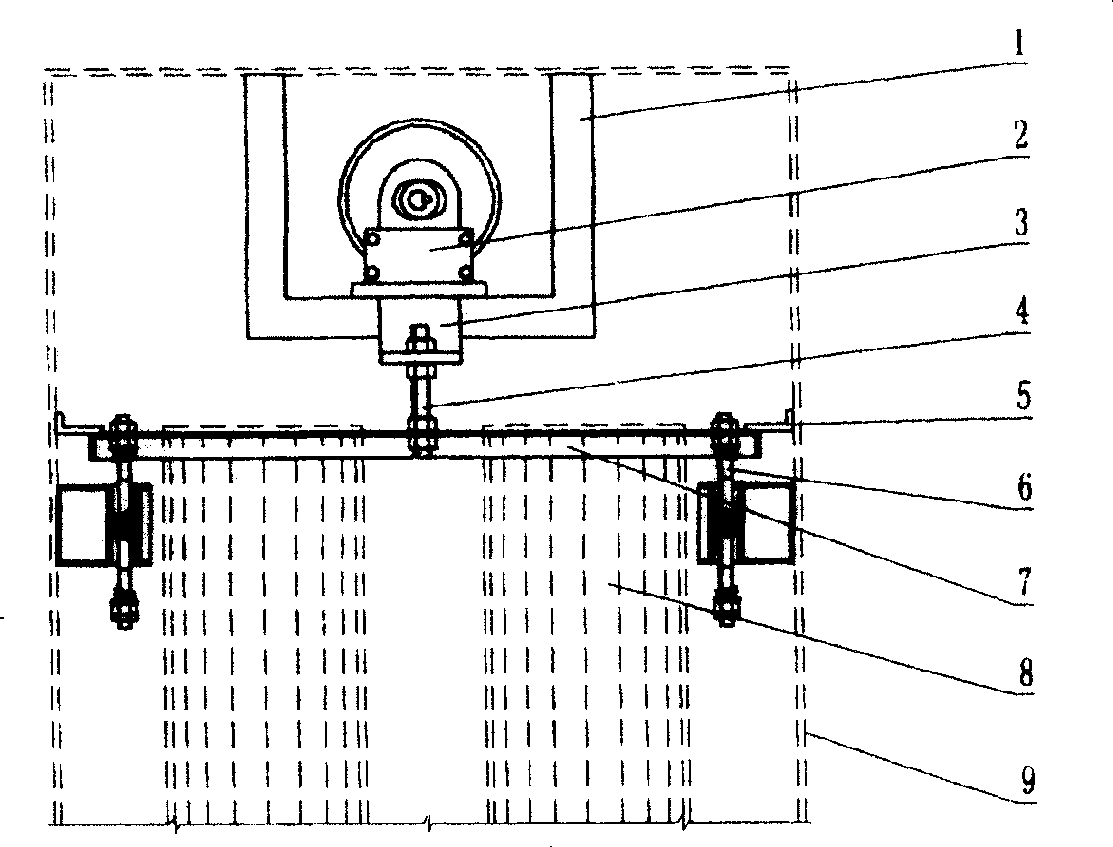

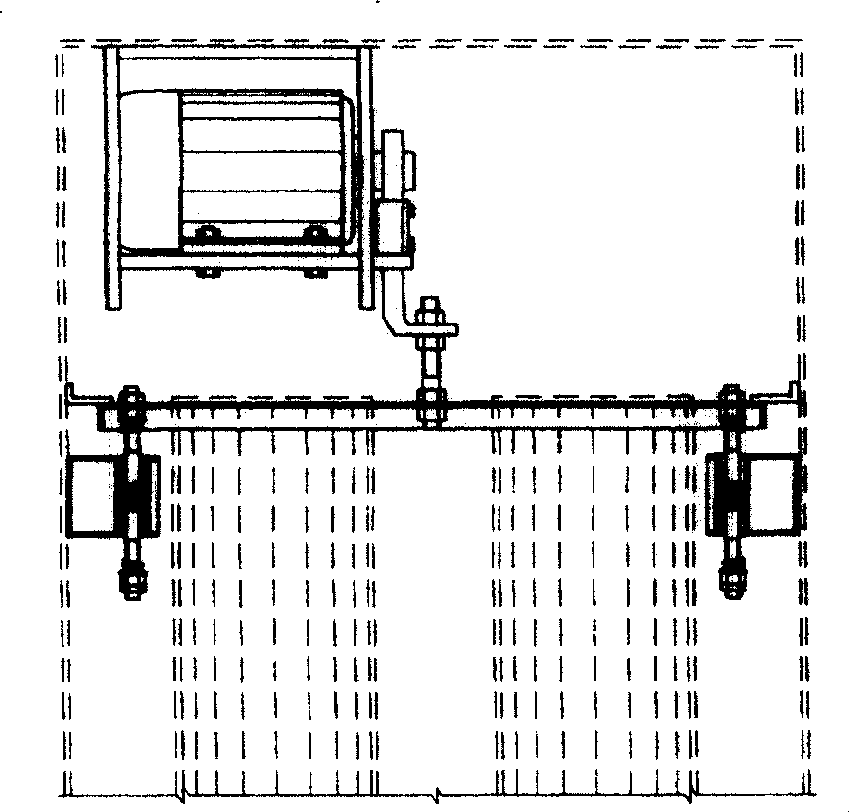

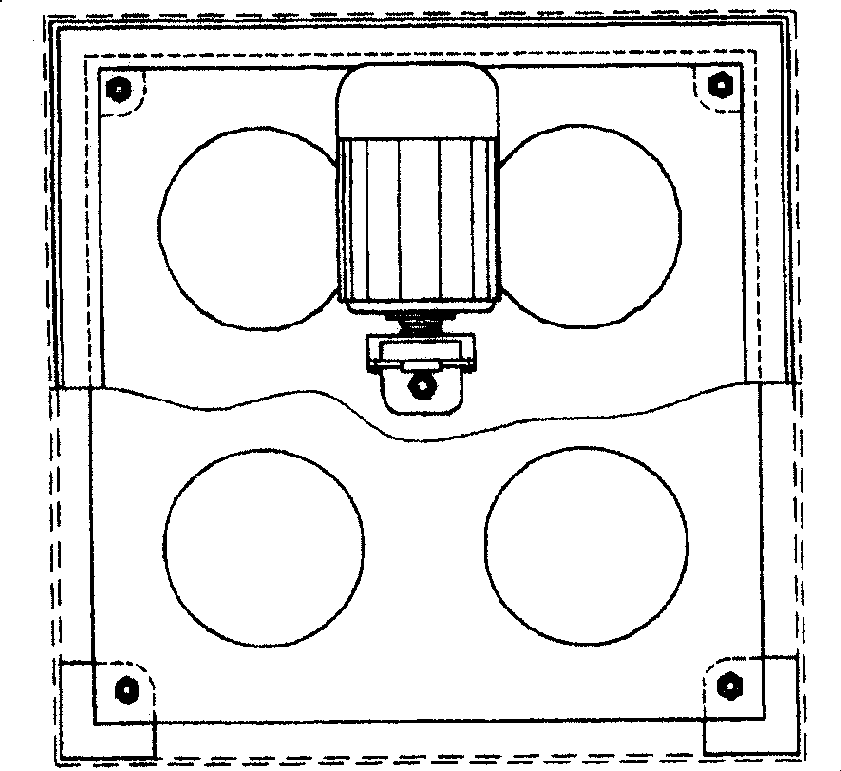

[0015] Embodiment 1: with reference to attached Figure 1~3 . Dust catcher multi-tube micro-vibration dust cleaning mechanism, it comprises filter 8, filter 8 is prior art and can be purchased out, and dust collector body 9 processing technology is prior art, does not describe here. Micro-vibration generator reference bracket 1 photo attached figure 1 Fixed (installed) on the dust collector body 9, the micro-vibration generator 2 is located (installed) in the micro-vibration generator support 1 and the micro-vibration transmission plate 3 in the micro-vibration generator refers to the attached figure 1 And connect with the center of the filter mounting plate 7 through the connecting rod 4, the four corners of the filter mounting plate 7 are located on the filter suspension positioning device 6 at the four corners inside the dust collector body and connected with the filter suspension positioning device, the surroundings of the filter mounting plate 7 It is connected with the...

Embodiment 2

[0018] Embodiment 2: On the basis of Embodiment 1, the micro-vibration method of the micro-vibration cleaning mechanism of the dust collector, the rotating power machine shaft drives the eccentric shaft to rotate, and the eccentric shaft performs rolling and rotating motion in the oblong hole on the upper part of the micro-vibration transmission plate and forces The micro-vibration transfer plate moves up and down, the micro-vibration transfer plate drives the connecting rod to move up and down, and the filter mounting plate on the filter suspension positioning device drives the filter mounting plate to vibrate up and down on the filter suspension positioning device through the connecting rod connected to it. The filter mounting plate installed inside the dust collector box (dust collector body) drives one or two or more filters to vibrate slightly, and at the same time, the filter mounting plate is connected with the flexible sealing frame in the dust collector body in a sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com