Pressure control valve

A pressure regulating valve and pressure regulating chamber technology, applied in the field of pressure regulating valves, can solve the problems of reducing the capacity of the pot, increasing the structural volume of the pressure reducing valve, etc., and achieve the effect of reducing the installation space and large space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

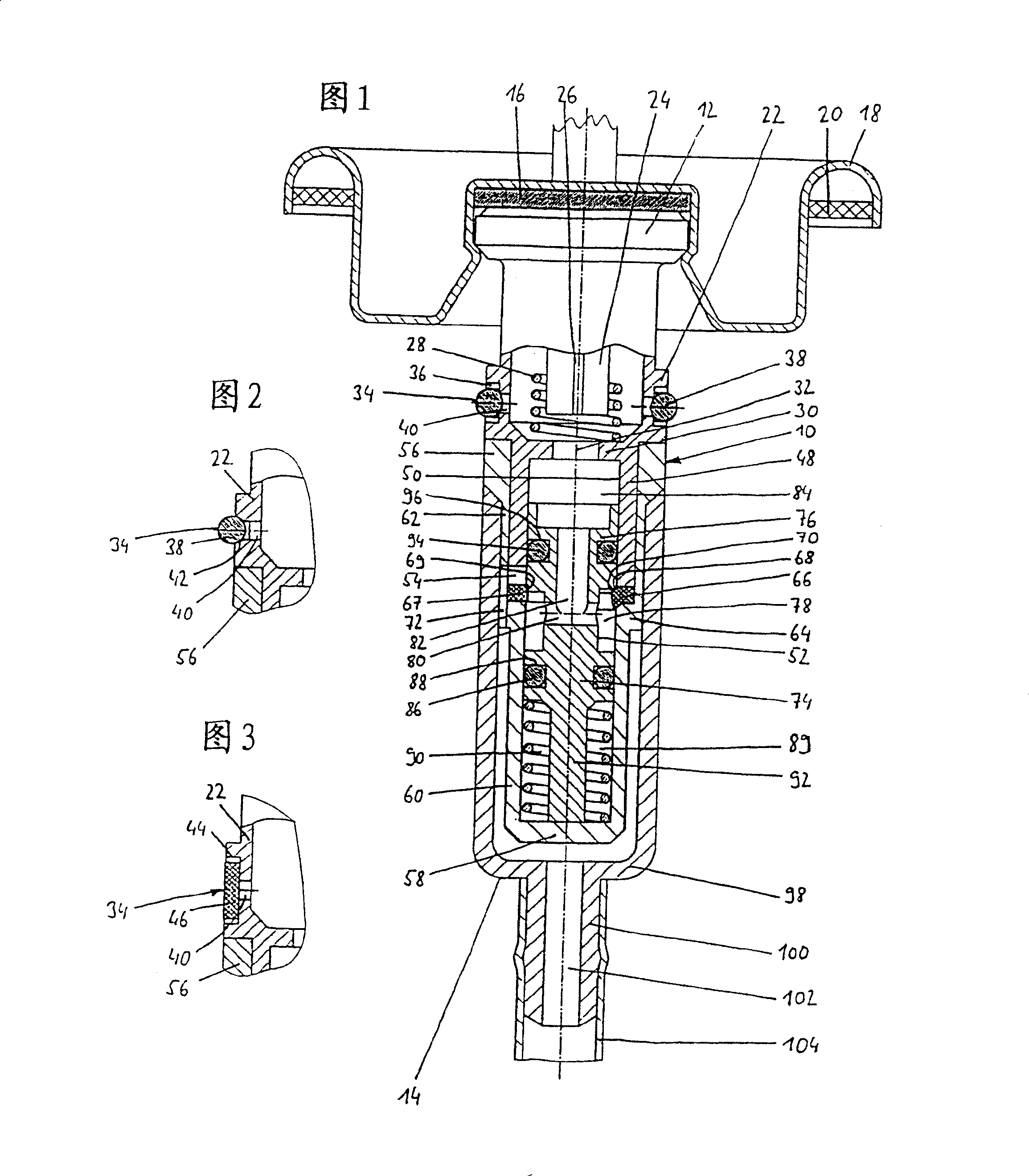

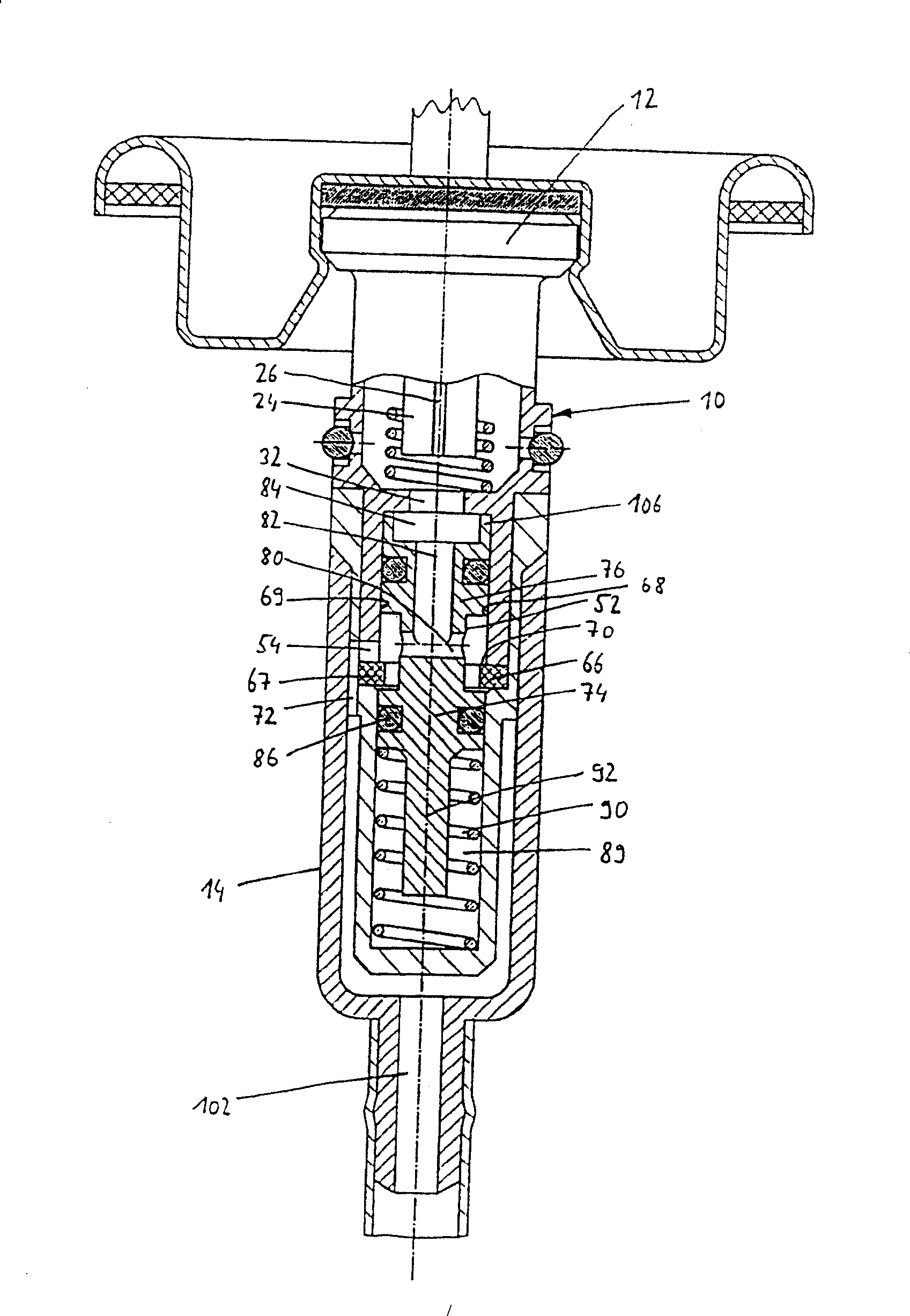

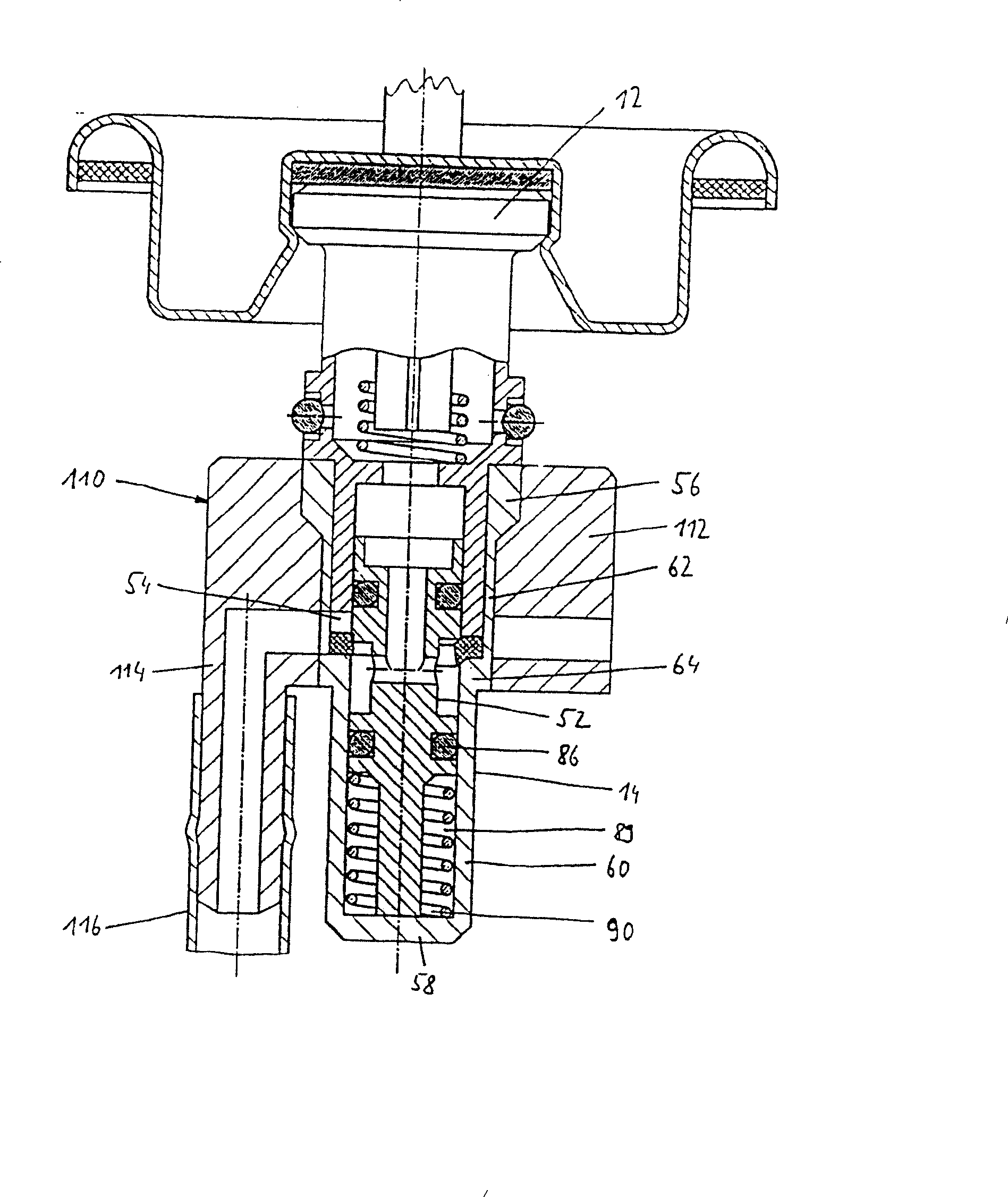

[0027] FIG. 1 shows a combined unit 10 comprising a spray valve 12 and a pressure regulating valve 14 . In its internal structure, the spray valve 12 corresponds to a conventional spray valve and its details are therefore not shown. This unit with the spray valve 12 is pre-assembled on a valve disc 18 and is sealed in a known manner with a sealing plate 16; the valve disc is then hermetically fixed to a watering can body with a sealing ring 20 on (not shown in the figure).

[0028]The spray valve has a spray valve housing 22 in which a stem 24 has an end 26 and a through hole and is movable against the load of a compression spring 28 . The spray valve housing 22 has an intermediate wall 30 with a through hole 32 , which separates the spray valve 12 from the pressure regulating valve 14 . In the wall of the spray valve housing 22 is provided an overpressure charging valve 34, which basically comprises an annular sealing element 38, which is arranged in a pretensioned manner i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com