Motor

A technology of motors and armatures, applied in the field of motors, can solve problems such as poor connection and weakened contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, an embodiment embodying the present invention will be described with reference to the drawings.

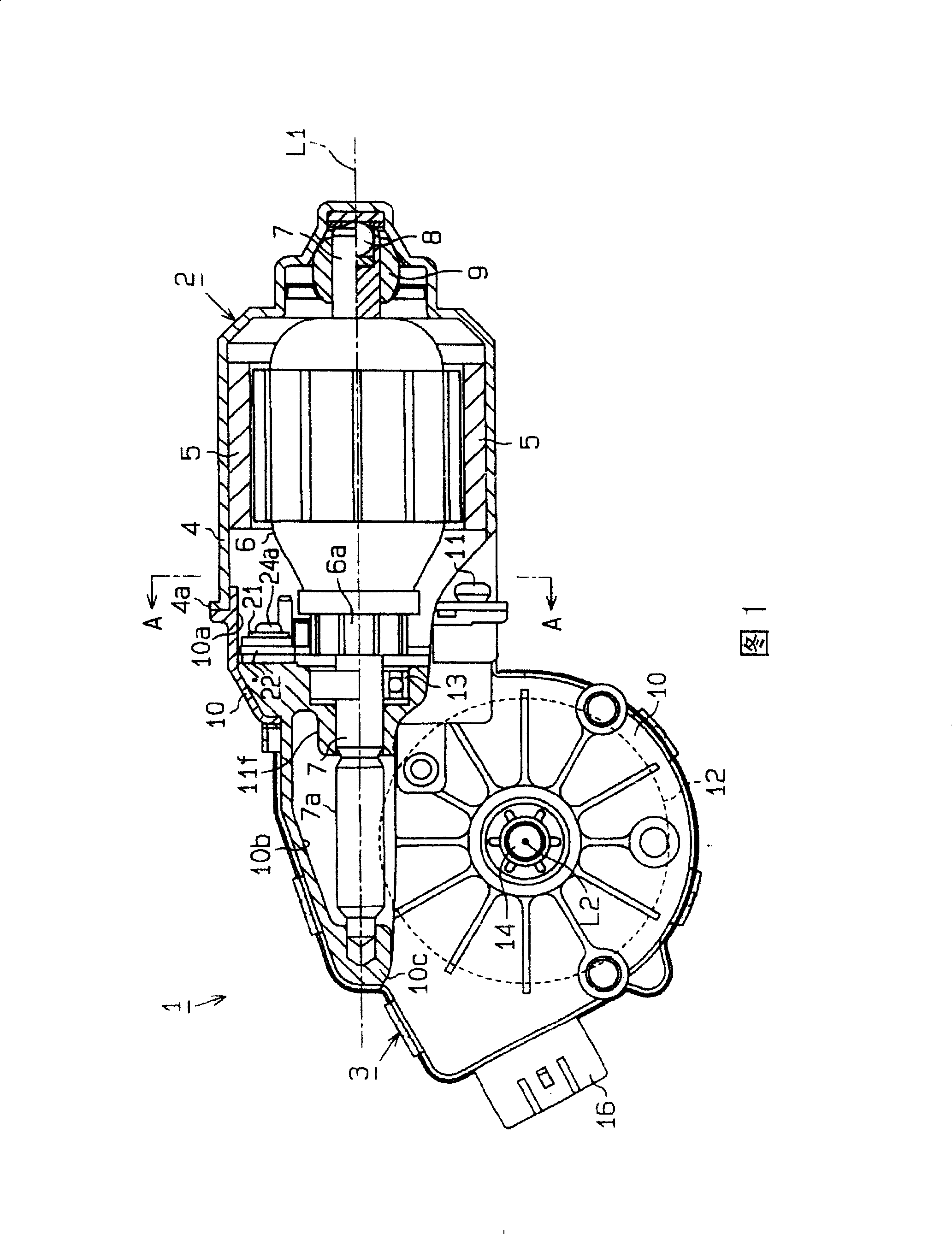

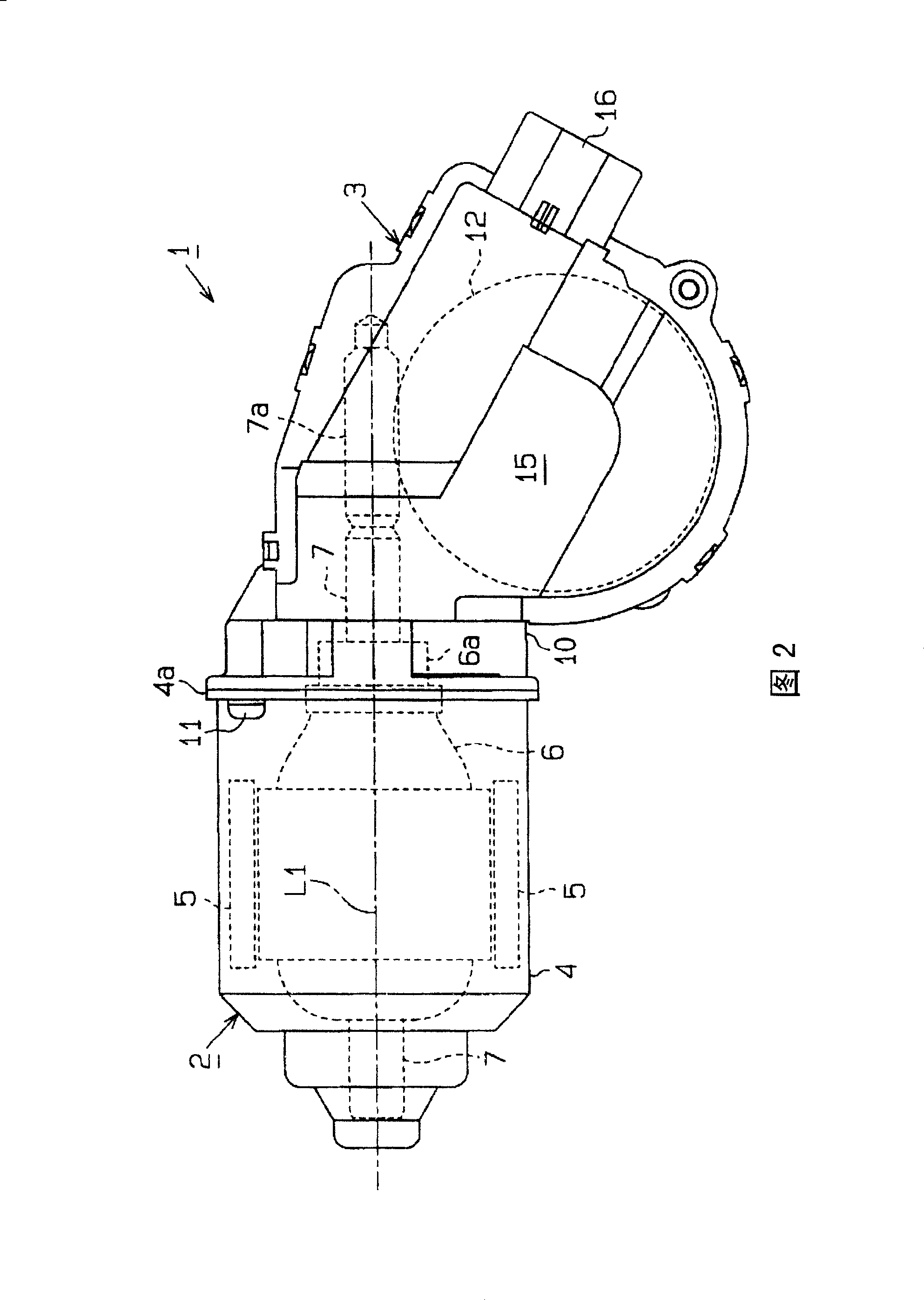

[0027] The wiper motor 1 shown in FIGS. 1 and 2 is used as a drive source of a vehicle wiper device for wiping off raindrops and the like adhering to a windshield (windshield) of a vehicle. This wiper motor 1 is composed of a motor main body 2 and a speed reduction unit 3 .

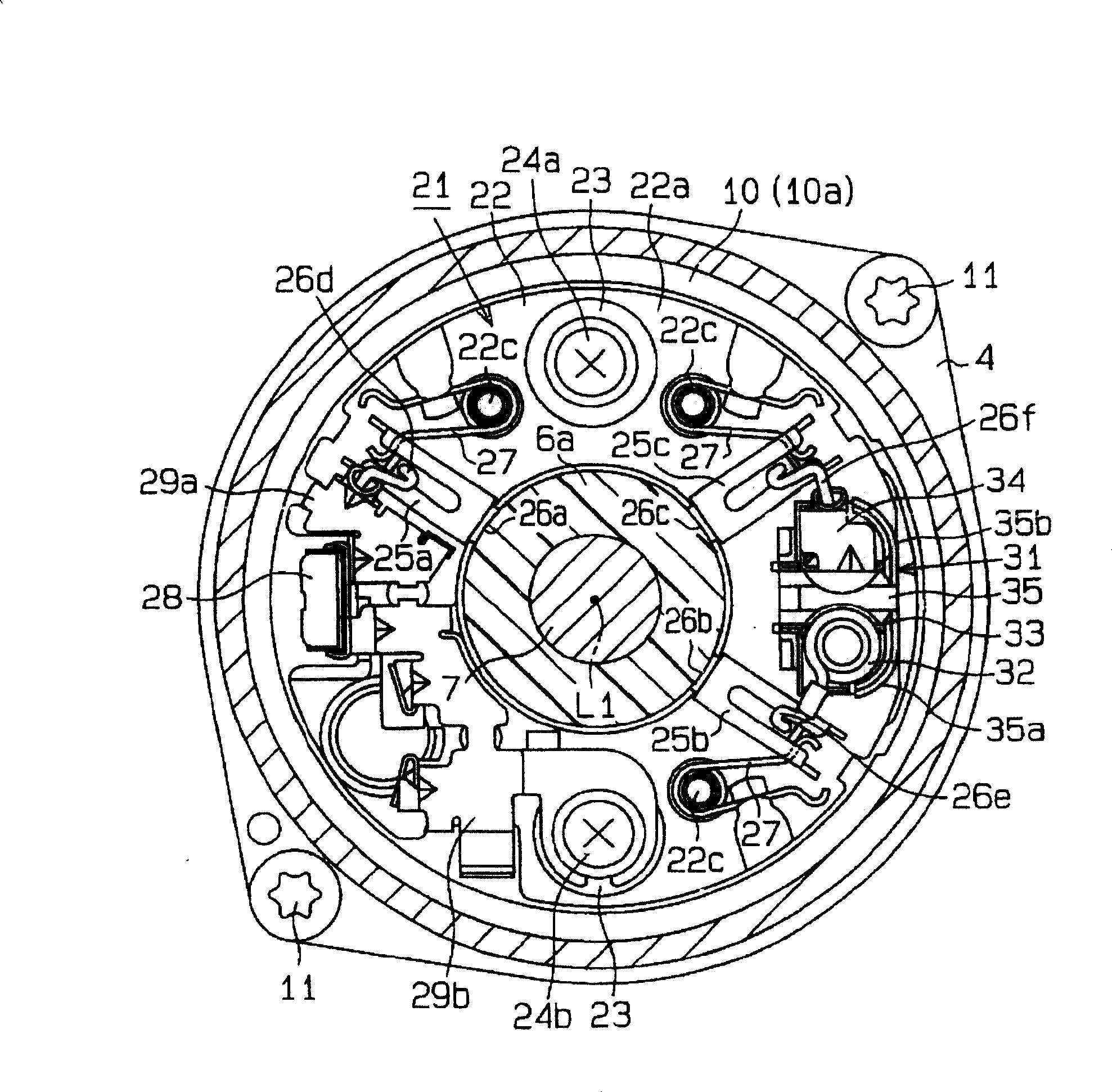

[0028] The yoke case 4 constituting the motor main body 2 is made of a conductive metal material and has a substantially cylindrical shape with a bottom. A plurality of magnets 5 are fixed to the inner peripheral surface of the yoke case 4 , and an armature 6 is rotatably accommodated inside each magnet 5 . At the bottom of the yoke case 4, a thrust bearing 8 and a radial bearing 9 that rotatably support the base end portion of the rotating shaft 7 of the armature 6 are provided. The gear case 10 of the deceleration unit 3 covering the head end side of the rotating shaft 7 forming the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com