A cylinder cleaning apparatus

A technology of equipment and cylinders, applied in office printing equipment, printing, printing presses, etc., can solve problems such as laborious and time-consuming cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

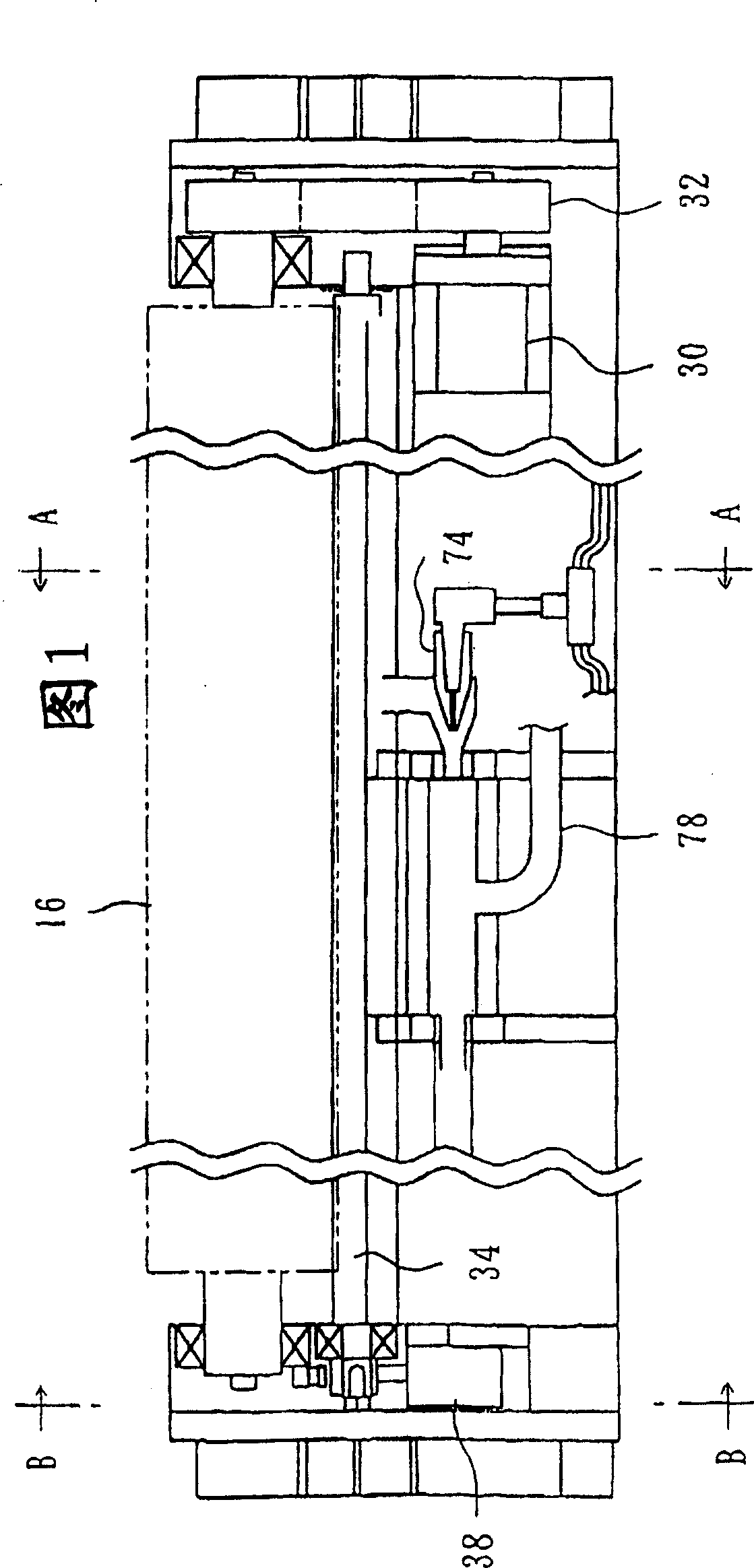

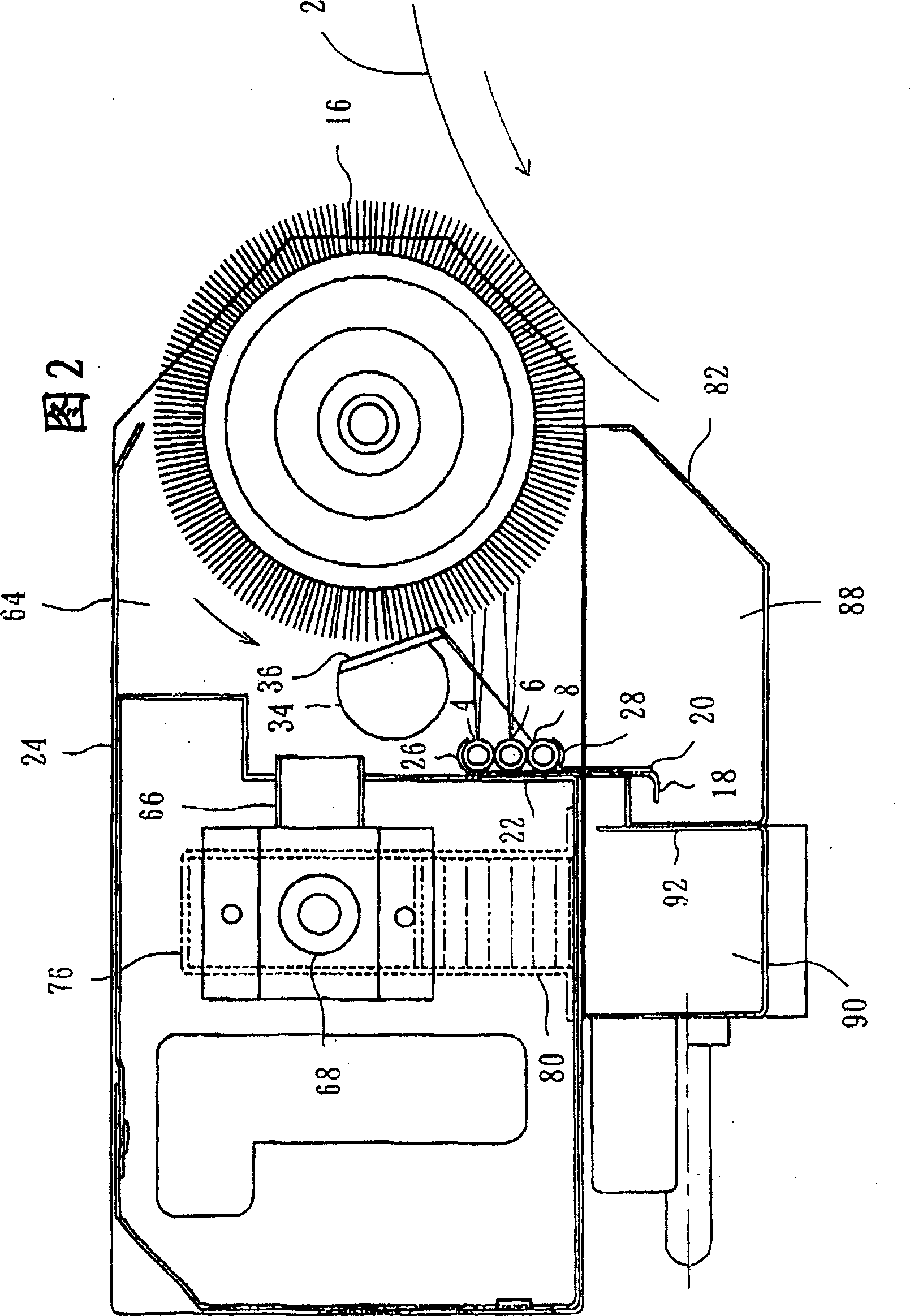

[0050] Referring now to the drawings, Figure 1 shows an apparatus according to the invention for cleaning a cylinder 2 in an offset or other printing press as shown in Figure 2, by means of a supply of cleaning fluid. The drum 2 includes an outer surface to which impurities such as dry ink, lint, and the like adhere. Impurities are removed from the outer surface during cleaning.

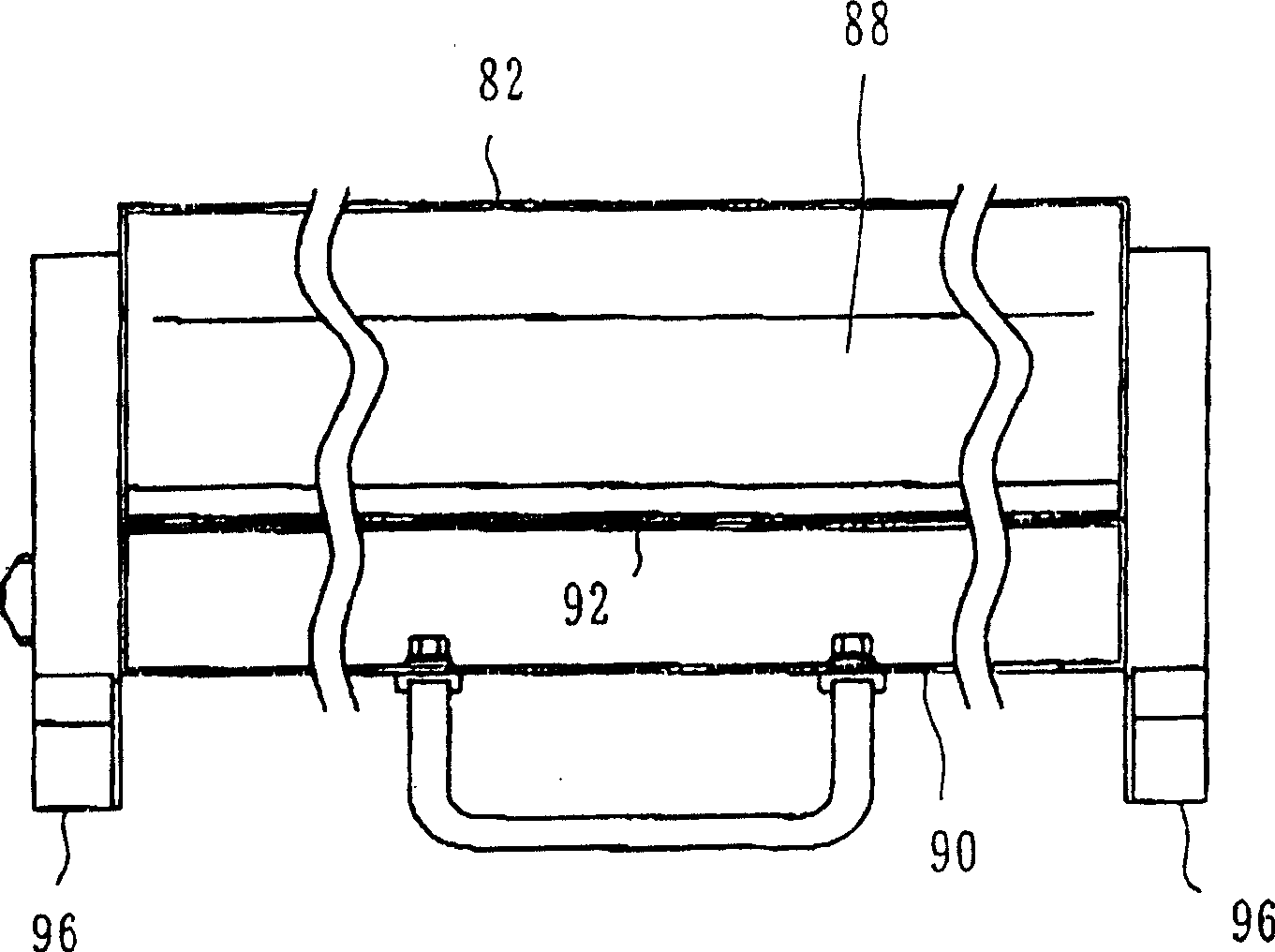

[0051] The device consists of a boom into which cleaning fluid is introduced under pressure. The spray bar comprises a pipe arrangement comprising a plurality of pipes 4, 6 and 8, said pipe arrangement comprising spray holes 10 formed thereon for spraying cleaning fluid, such as Figure 8 shown. Tubes 4, 6 and 8 are made of elastic and flexible material such as polyurethane, nylon, fluororesin (Teflon), silicone rubber, polyethylene or other high polymer. The orifices 10 include pinholes each formed in the tubes 4, 6 and 8 by penetrating the tubes 4, 6 and 8 with a needle 12, as shown in FIG. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com