A polarity testing device of electronic elements of automatic braiding machines and a testing method thereof

An automatic braiding machine and polarity detection technology, which is applied in the direction of measuring devices, instruments, packaging, etc., to achieve the effects of cost reduction, simple and compact devices, and scientific and reasonable detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0024] Taking the SOT automatic taping machine as an example below, the technical composition and detection method of the present invention are described in detail.

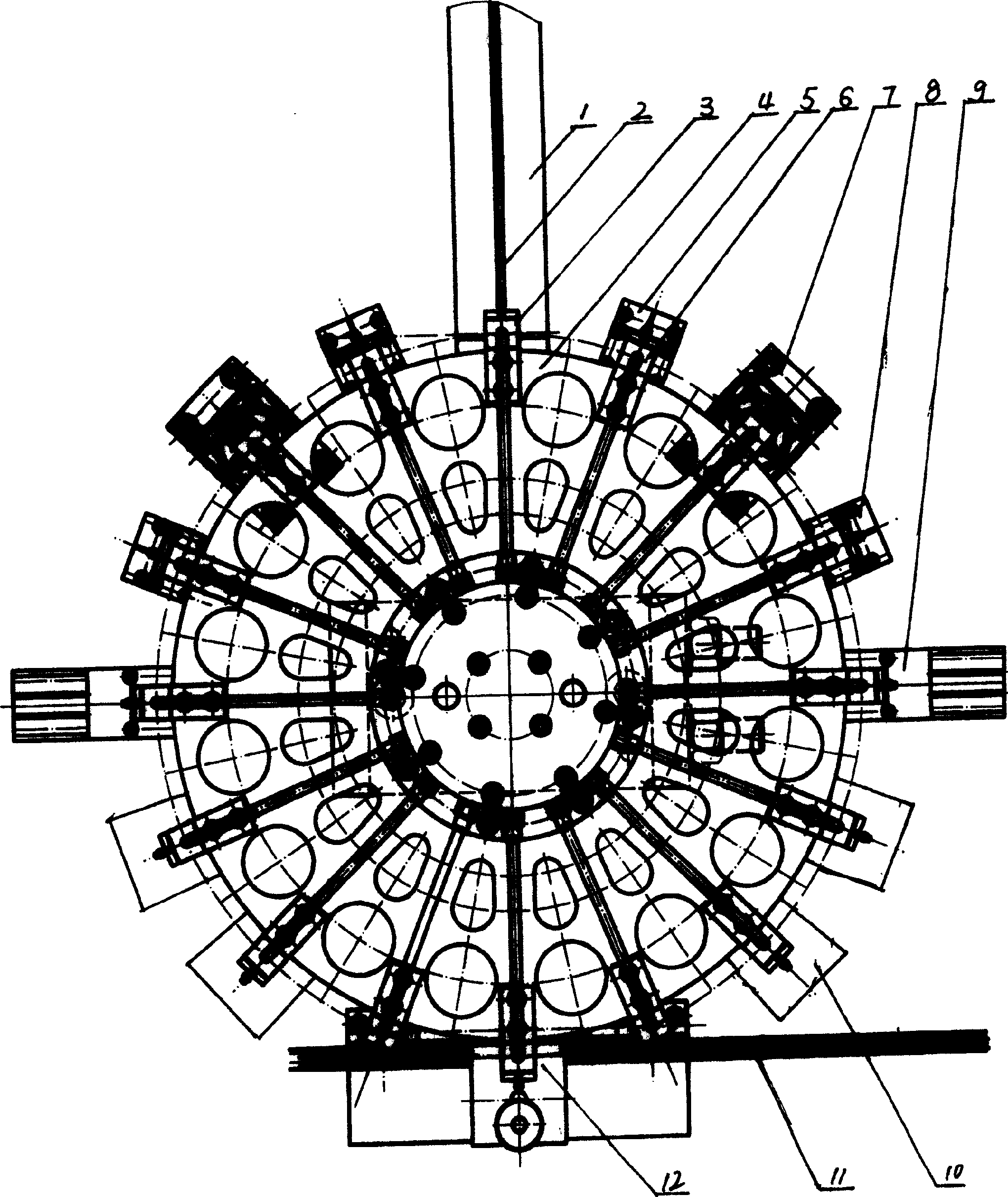

[0025] The SOT automatic tape braiding machine uses the linear feeder 1 to transport the device to the main pick-up station 3 installed at its end through the material guide groove 2, and the device is transferred to the braiding station through the suction head 6 on the swing plate. There are 12 main unloading stations in 11 places, and the finished products are finished after braiding.

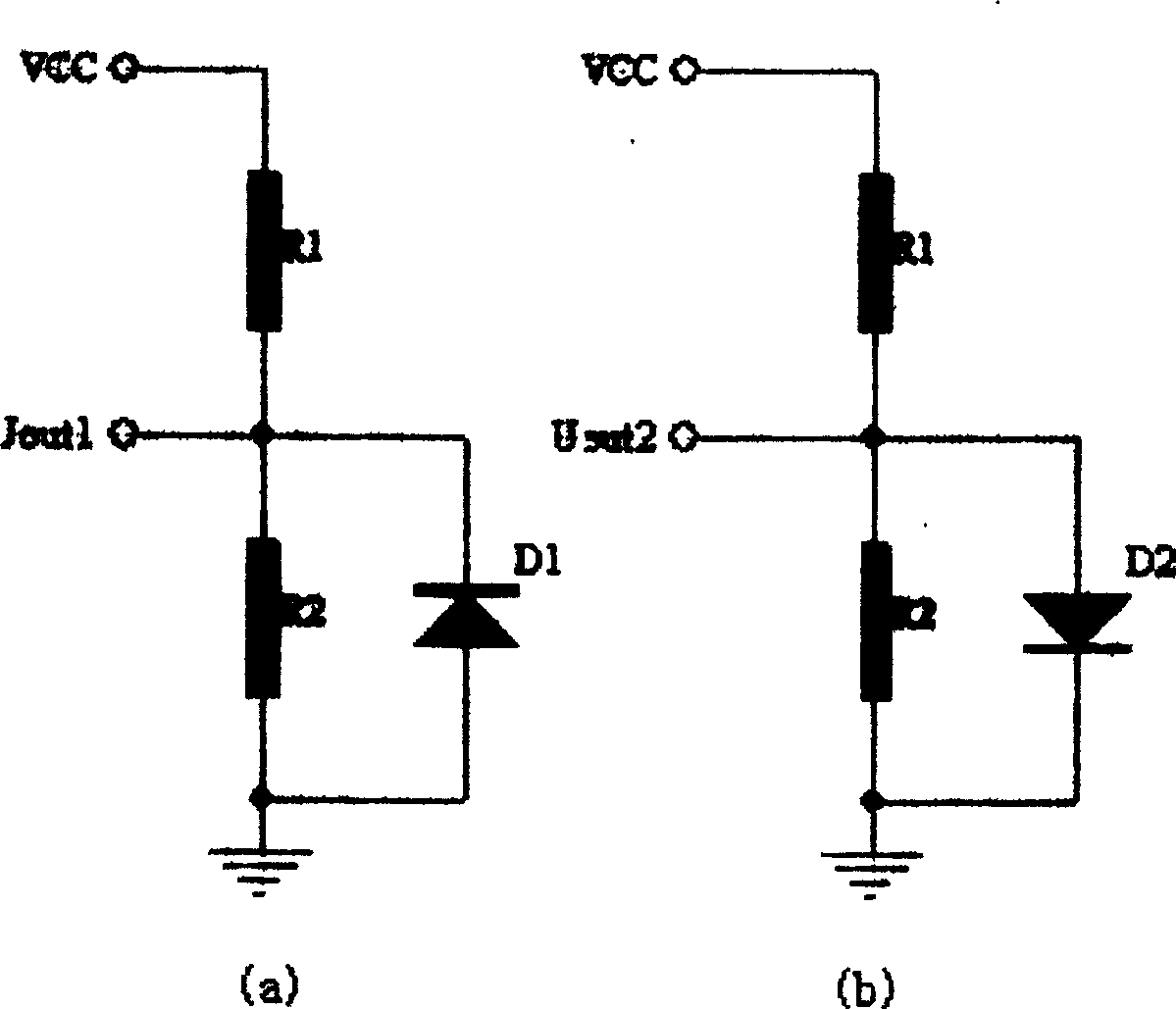

[0026] The following will first describe the polarity detection device of the automatic tape machine:

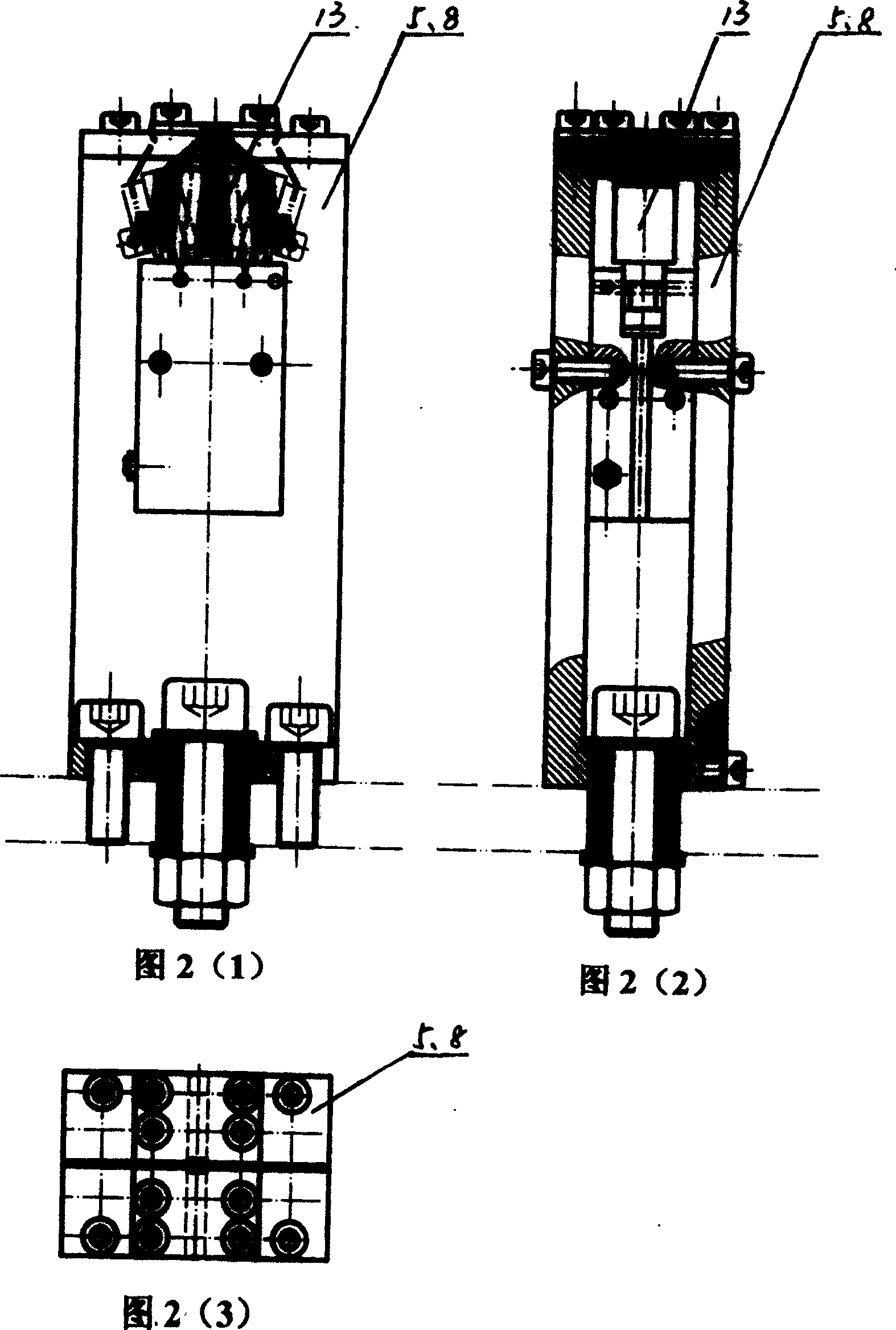

[0027] There are several vacuum suction heads evenly distributed on the outer edge of the circumference of the braiding machine's swing plate, and the suction heads of the swing plate are symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com