Food processing equipment based on rotary cutting

A processing equipment and food processing technology, which is applied in food processing, metal processing, food science, etc., can solve the problems of manual scraping of coconut pulp, such as large differences in shape, time-consuming, labor-intensive, and high risk of coconut pulp, and increase scraping efficiency. , uniform shape, and the effect of reducing dangerous situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

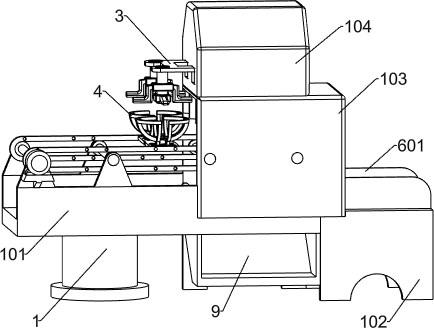

[0034] A food processing equipment based on rotary cutting, such as figure 1 and figure 2 As shown, it includes a round table base 1, a connecting frame 101, a square base 102, a support frame 103, a protective frame 104, a support seat 105, a multifunctional tool 2, a straightening device 3 and a conveying clamping device 4; the round table base 1 is placed on In the lower left part of the device, the upper surface of the round platform base 1 is fixedly connected with the connecting frame 101, the upper part of the left side of the square base 102 is fixedly connected with the right side of the connecting frame 101, and the lower surface of the support frame 103 is fixedly connected with the right upper surface of the connecting frame 101. There are two square holes on the left side of the protective frame 104, the lower surface of the protective frame 104 is aligned and fixedly connected to the left side of the upper surface of the support frame 103, and there are four sup...

Embodiment 2

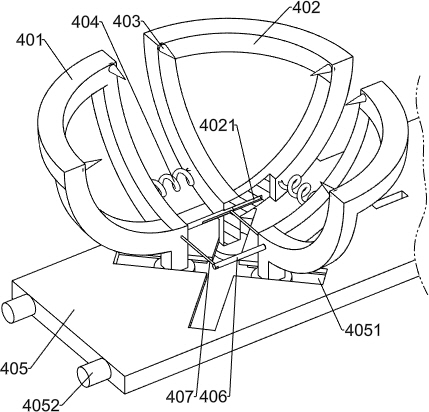

[0037] On the basis of Example 1, such as Figure 3-Figure 6 As shown, the multifunctional tool 2 includes a first support rod 201, a first protective shell 202, a first spring 2021, a special-shaped rack block 2022, a tool bearing seat 203, a U-shaped soft knife 204, a scraper 205, and a limit base 2051, second spring 2052, probe rod 206, third spring 2061, support sleeve rod 2062, crush assembly 207, auxiliary reset assembly 208, first motor 408, first gear 210 and second gear 211; first support rod 201 is provided with two, the first support rod 201 is arranged inside the protection frame 104, the first support rod 201 is connected with the straightening device 3 through the bearing rotation, the first support rod 201 bottom has a square through hole that runs through front and back, the first The lower part of the support rod 201 has two holding grooves, the square through hole on the first support rod 201 communicates with the two holding grooves, the lower surface of the...

Embodiment 3

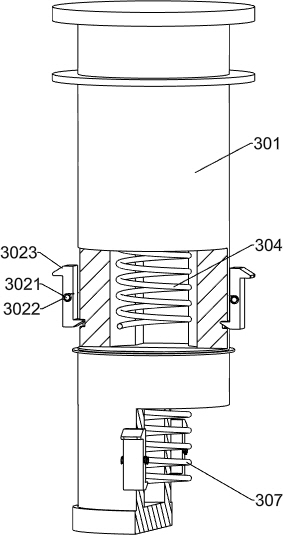

[0044] On the basis of Example 2, such as Figure 7 and Figure 8 As shown, the straightening device 3 includes a short-range cylinder 308 and a connecting support plate 309; the short-range cylinder 308 is arranged on the left part of the inner upper surface of the protection frame 104, and the lower end of the short-range cylinder 308 is fixedly connected with a connecting support plate 309, and the connecting support plate 309 is connected to the protection frame. The left side of the frame 104 is slidingly connected, and the right part of the connecting support plate 309 is connected with the upper part of the first support rod 201 through bearing rotation. The left wall square hole of the first motor 408 is fixedly connected to the right part of the upper surface of the connection support plate 309, and the output shaft of the first motor 408 passes through the connection support plate 309 and is rotatably connected with it.

[0045] Such as Figure 8-Figure 10 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com