Processing equipment assembly

A process equipment and equipment technology, applied in semiconductor/solid-state device manufacturing, conveyor objects, electrical components, etc., can solve the problems of incomplete protection of the copper metal layer, etc., and achieve the effect of flexible process, shortened process time, and more efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above-mentioned purpose, features and advantages of the present invention more comprehensible, a preferred embodiment is exemplified below and described in detail in conjunction with the accompanying drawings.

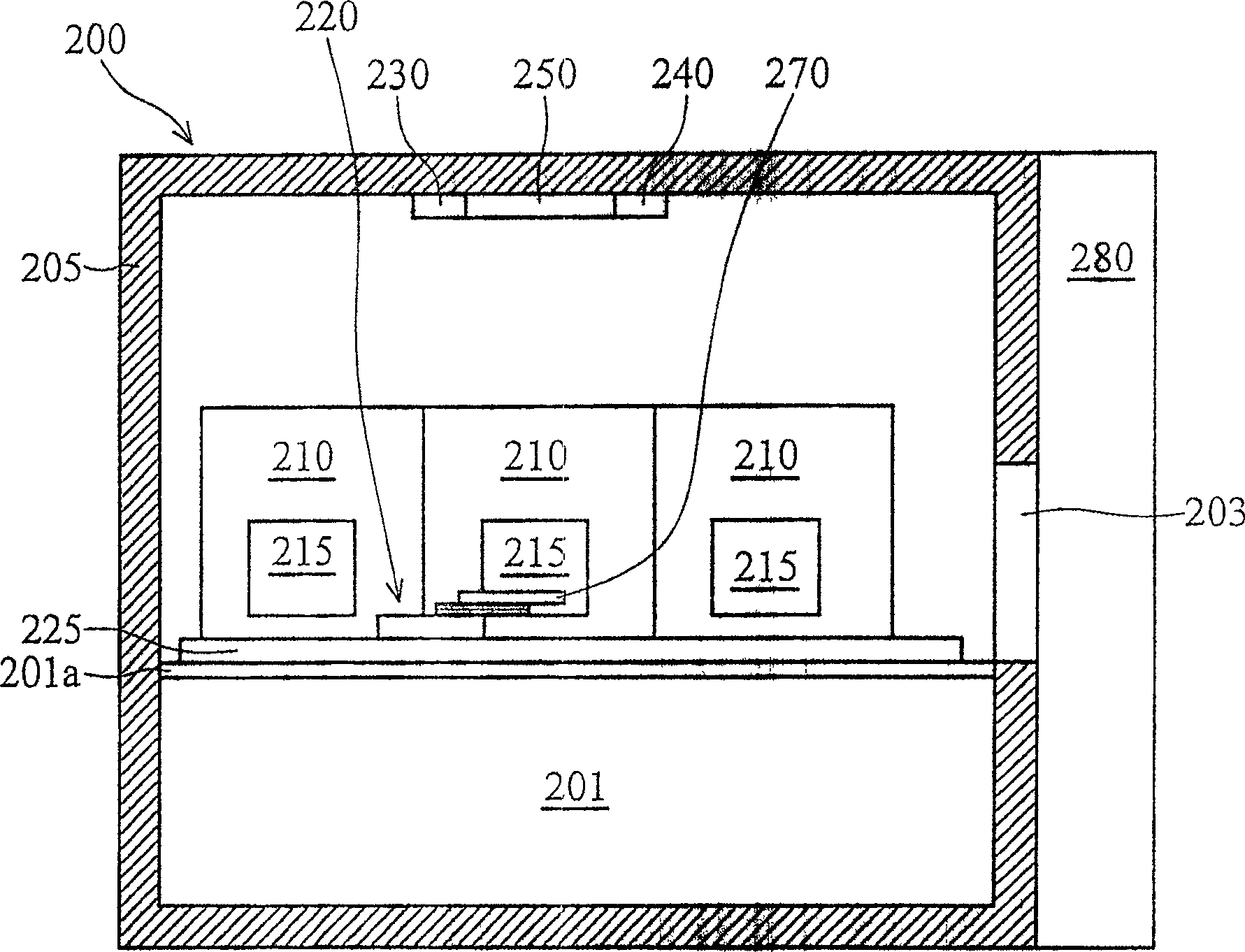

[0030] figure 2It is a schematic cross-sectional view of a process equipment group according to an embodiment of the present invention. The process equipment group includes a closed cavity 200 , at least one process chamber 210 (preferably a plurality of them), at least one transport device 220 and one or more valves, such as valves 230 and 240 . A platform 201 , table top or other supporting devices are disposed in the airtight cavity 200 to support the transfer device 220 carrying a substrate 270 and the process chamber 210 . In one embodiment, the transport device 220 moves along a track or guide path 225 provided on the platform 201 .

[0031] The sealed cavity 200 includes a closed space filled with gas. In the embodiment, the close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com