Vacuum control system

A vacuum control and high vacuum technology, applied in the control/regulation system, fluid pressure control, non-electric variable control and other directions, can solve the problems of vacuum exhaust system 1 failure, oil seal medium splashing, vacuum degree limitation, etc. Ineffective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

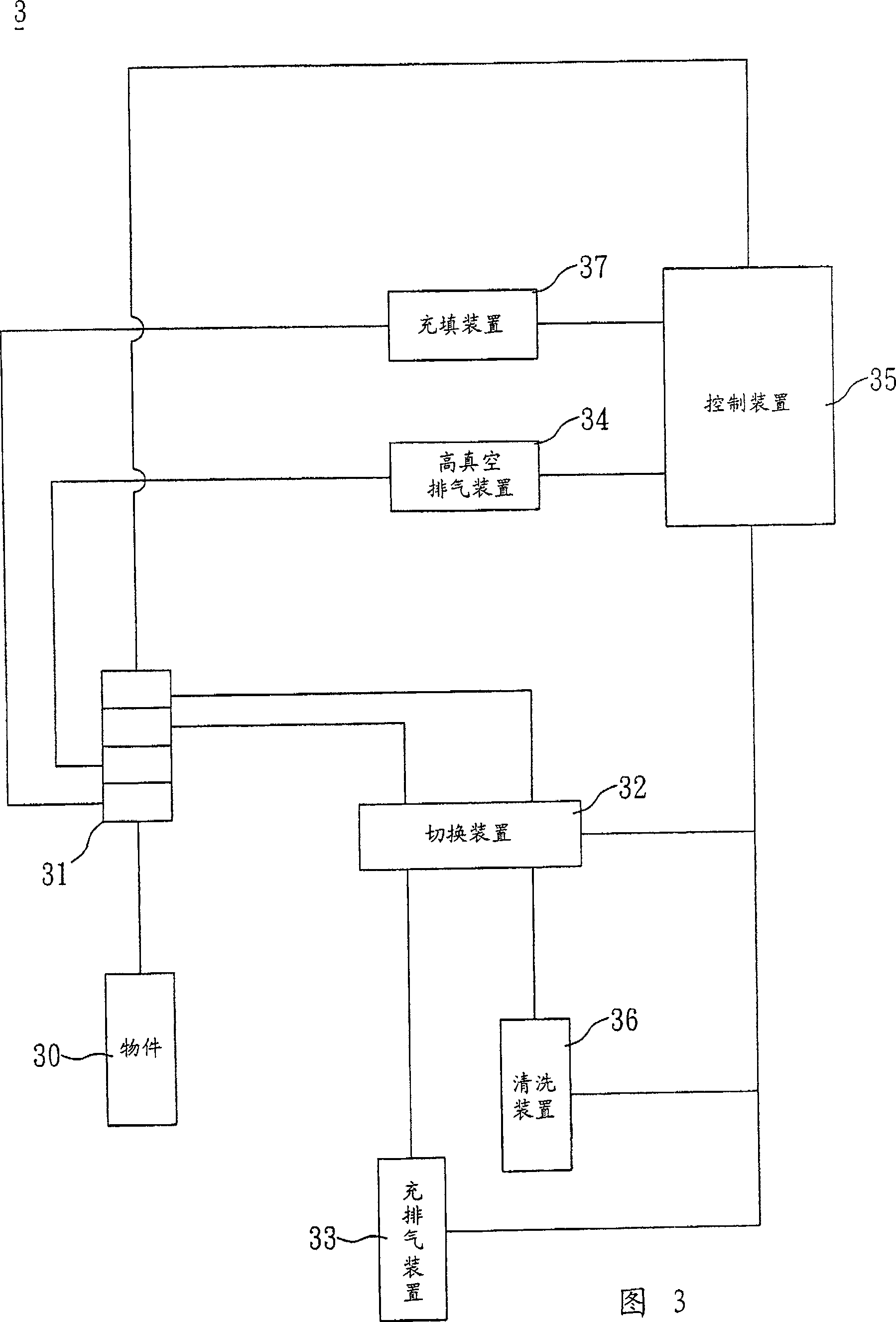

[0040] Hereinafter, a vacuum control system according to a preferred embodiment of the present invention will be described with reference to the related drawings, wherein the same components will be described with the same reference numerals.

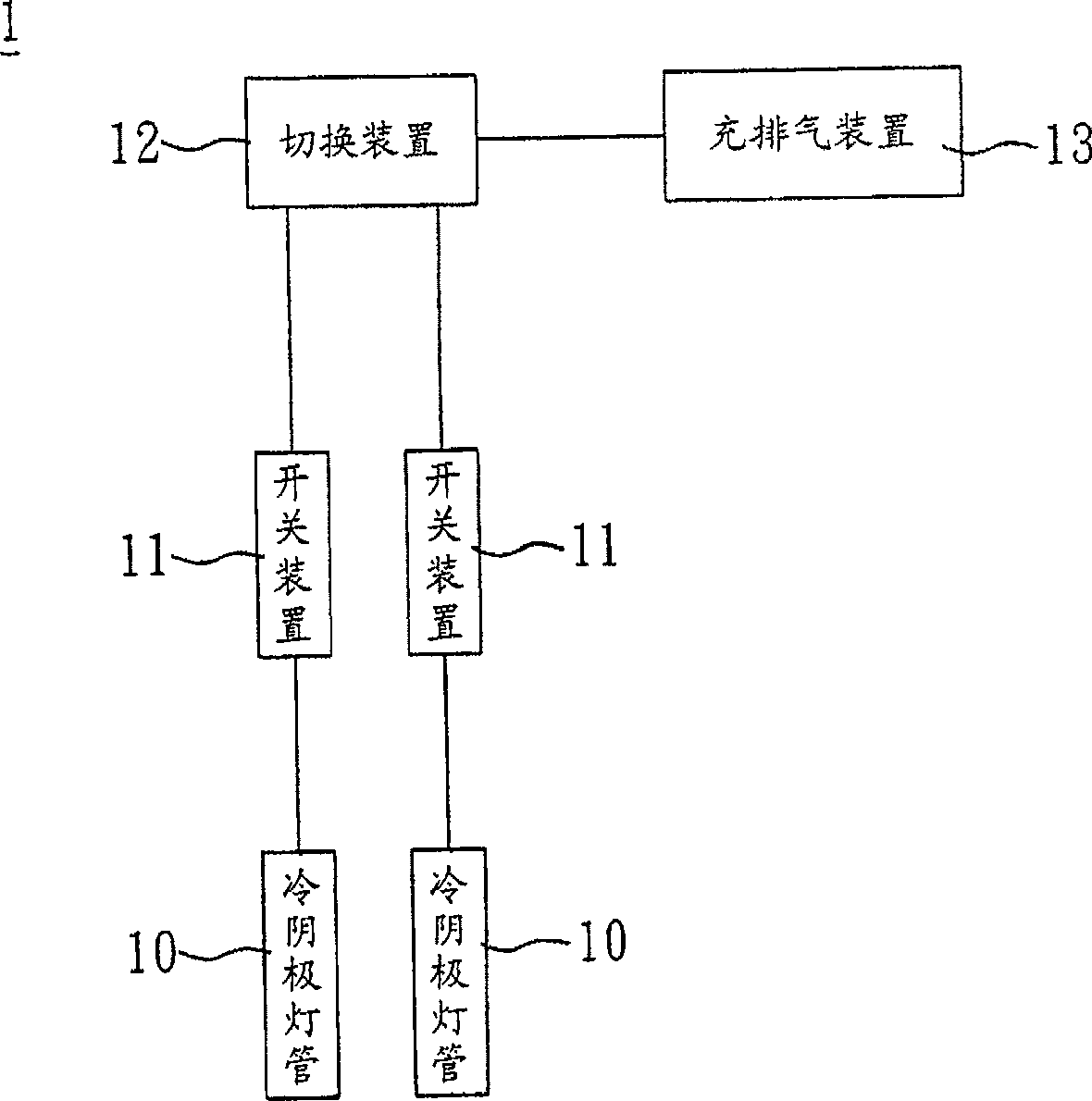

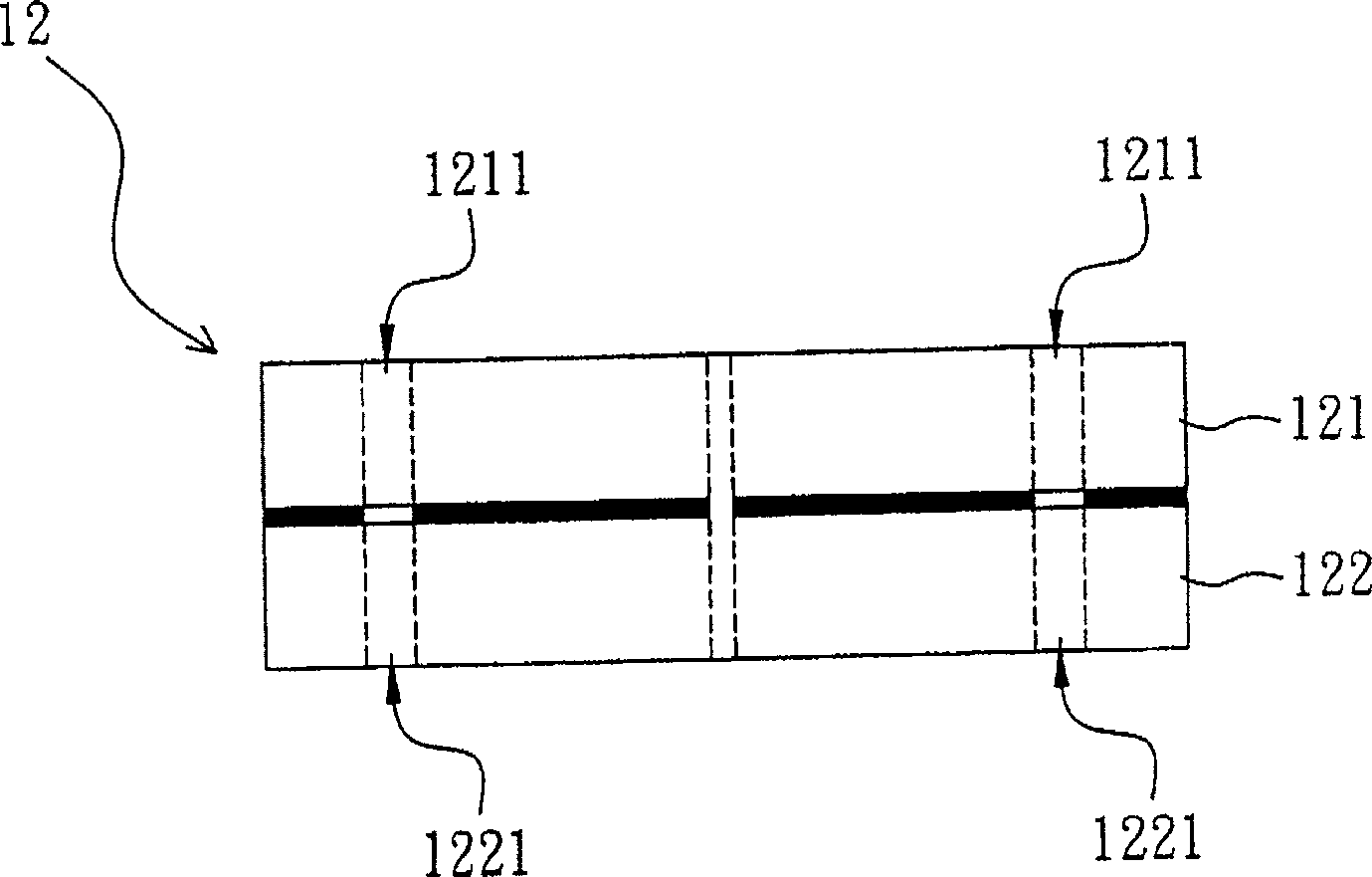

[0041] Referring to Fig. 3, a vacuum control system 3 according to a preferred embodiment of the present invention includes a switching device 31, a switching device 32, a charging and exhausting device 33, a high vacuum exhausting device 34 and a control device 35 .

[0042] The switch device 31 corresponds to an object 30 to be evacuated. In this embodiment, the object 30 may be a cold cathode lamp.

[0043] The switch device 32 is connected with the switch device 31, the inflation and exhaust device 33 is connected with the switch device 32, and the high vacuum exhaust device 34 is directly connected with the switch device 31. In this embodiment, the device 31 , 32 , 33 , and 34 can be connected by at least one pipeline respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com