Gas-containing active lactic acid bacteria beverage without adding stabilizer and preparation method thereof

A technology of active lactic acid bacteria and stabilizers, which is applied in the direction of lactobacillus, dairy products, bacteria used in food preparation, etc., can solve problems such as insufficient air content, foam overflow, complex stabilizer components, etc., and achieve refreshing taste, good taste, unique flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

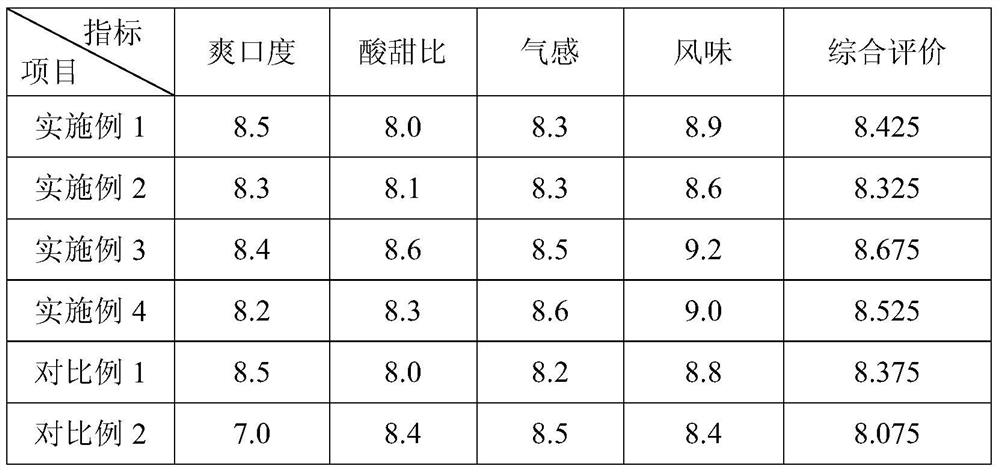

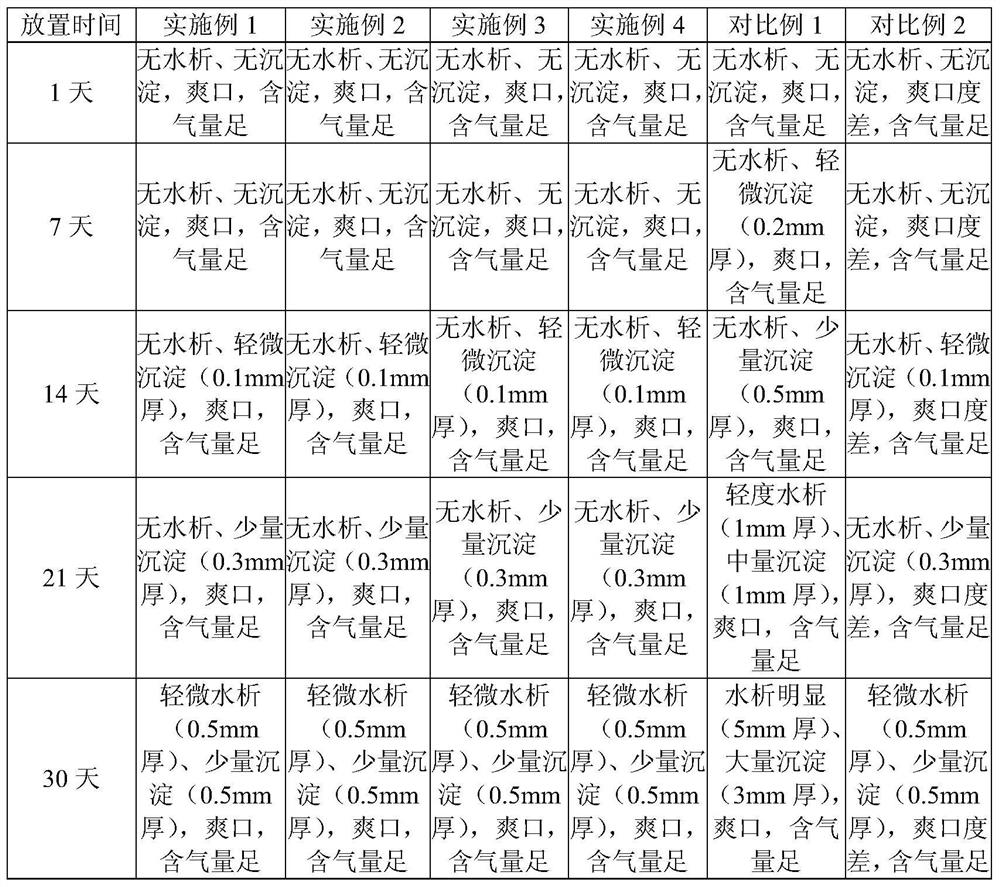

Examples

Embodiment 1

[0032] 1. Raw material formula

[0033]Fermentation substrate: 25g of skim milk powder, 5g of anhydrous glucose, supplemented with water to 100g;

[0034] Strains: Lactobacillus paracasei 0.01g;

[0035] Sugar solution: steviol glycoside 0.7g, 100% water;

[0036] Edible dry ice 0.6g;

[0037] Other raw materials: essence 0.1g.

[0038] 2. Production method:

[0039] (a) Add skim milk powder into water to make the material, wherein the hydration temperature is 55°C, and the hydration time is 40 minutes. During the batching process, anhydrous glucose is added to obtain the fermentation substrate; the fermentation substrate is under the pressure of 30-150bar After homogenization, carry out the Maillard reaction at 120°C for 30 minutes, cool the material to 37°C, add the bacteria by aseptic operation, fully shake and mix, and ferment for 72 hours. When the acidity of the final material reaches 200°T, stop the fermentation and break down. After milking, cool to below 10°C to ...

Embodiment 2

[0043] 1. Raw material formula

[0044] Fermentation substrate: 30g of skim milk powder, 5g of anhydrous glucose, supplemented with water to 100g;

[0045] Strains: 0.005g of Lactobacillus casei, 0.01g of Lactobacillus paracasei;

[0046] Sugar liquid: aspartame 0.7g, 100% water;

[0047] Edible dry ice 0.6g;

[0048] Other raw materials: essence 0.1g.

[0049] 2. Production method:

[0050] (a) Add skim milk powder into water to make the material, wherein the hydration temperature is 55°C, and the hydration time is 40 minutes. During the batching process, anhydrous glucose is added to obtain the fermentation substrate; the fermentation substrate is under the pressure of 30-150bar After homogenization, carry out the Maillard reaction at 100°C for 2 hours, cool the material to 37°C, add the bacteria by aseptic operation, fully shake and mix, and ferment for 72 hours. When the acidity of the final material reaches 200°T, stop the fermentation and break down. After milking, ...

Embodiment 3

[0054] 1. Raw material formula

[0055] Fermentation substrate: 35g of skim milk powder, 10g of anhydrous glucose, supplemented with water to 100g;

[0056] Strains: 0.01g of Lactobacillus paracasei, 0.005g of Lactobacillus plantarum;

[0057] Sugar liquid: white granulated sugar 140g, water 100g;

[0058] Edible dry ice 0.6g;

[0059] Other raw materials: essence 0.1g.

[0060] 2. Production method:

[0061] (a) Add skim milk powder into water to make the material, wherein the hydration temperature is 55°C, and the hydration time is 40 minutes. During the batching process, anhydrous glucose is added to obtain the fermentation substrate; the fermentation substrate is under the pressure of 30-150bar After homogenization, carry out the Maillard reaction at 100°C for 2 hours, cool the material to 37°C, add the bacteria by aseptic operation, fully shake and mix, and ferment for 72 hours. When the acidity of the final material reaches 200°T, stop the fermentation and break down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com