Novel asphalt mixture for pavement construction

A kind of asphalt and mixture technology, applied in the field of new asphalt mixture, can solve the problems of poor low-temperature cracking resistance, low anti-aging performance, and easy rutting on the road surface, so as to improve the ability to resist rutting deformation, reduce the heat absorption capacity of the road surface, Improve the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

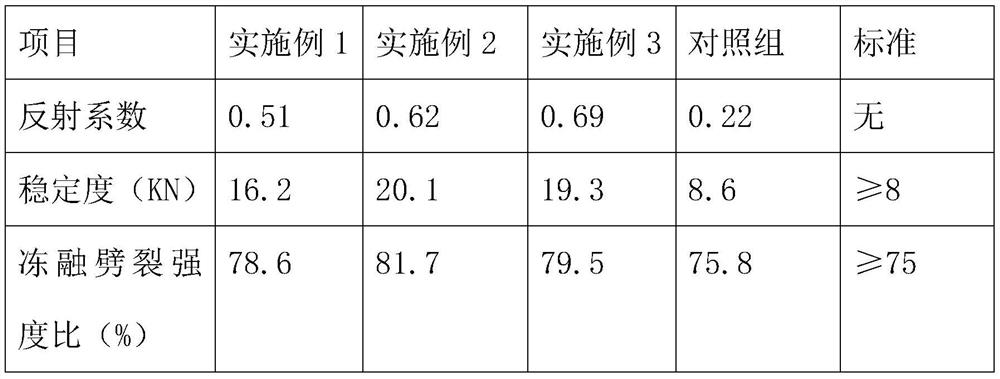

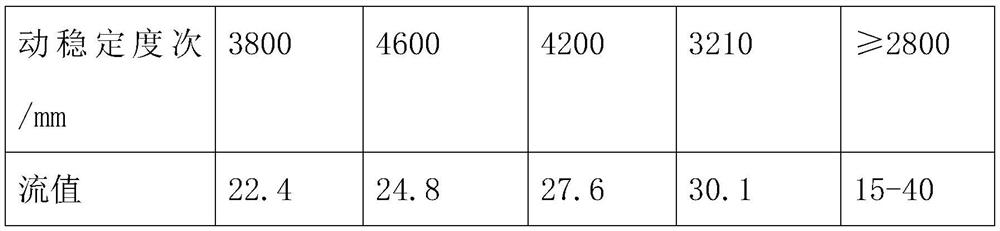

Embodiment 1

[0023] A new type of asphalt mixture for pavement construction, characterized in that it includes the following raw materials and percentages: rock asphalt modified asphalt 3%, mineral aggregate 4%, aggregate 90.7%, coupling agent 0.3%, filler 2 %; Wherein, the rock asphalt modified asphalt comprises rock asphalt, base asphalt, stabilizer, nano vitrified microbeads, and the rock asphalt is 3% in the rock asphalt modified asphalt, and the base asphalt is in The rock bituminous modified asphalt percentage is 92.8%, the stabilizer is 0.2% in the rock bituminous modified asphalt, and the nano vitrified microbeads are 4% in the rock bituminous modified asphalt; The aggregate is one or a combination of limestone, volcanic rock, andesite; the filler is silica; the coupling agent is a titanate coupling agent, a silane coupling agent, or a zirconium coupling agent at least one or a combination thereof.

[0024] In addition, the preparation method of the rock asphalt modified asphalt: ...

Embodiment 2

[0031] A new type of asphalt mixture for pavement construction, characterized in that it includes the following raw materials and percentages: rock asphalt modified asphalt 5%, mineral aggregate 5%, aggregate 86%, coupling agent 0.6%, filler 2.5% %; wherein, the rock asphalt modified asphalt comprises rock asphalt, base asphalt, stabilizer, nano-vitrified microbeads, and the rock asphalt is 4% in the rock asphalt modified asphalt percentage, and the base asphalt is in The rock bitumen modified bitumen percentage is 90.3%, the stabilizer is 0.5% in the rock bitumen modified bitumen, and the nano vitrified microbead is 5% in the rock bitumen modified bitumen; The aggregate is one or a combination of limestone, volcanic rock, andesite; the filler is silica; the coupling agent is a titanate coupling agent, a silane coupling agent, or a zirconium coupling agent at least one or a combination thereof.

[0032] In addition, the preparation method of the rock asphalt modified asphalt:...

Embodiment 3

[0039]A new type of asphalt mixture for road construction, characterized in that it includes the following raw materials and percentages: rock asphalt modified asphalt 8%, mineral aggregate 6%, aggregate 90.7%, coupling agent 1%, filler 3 %; wherein, the rock asphalt modified asphalt comprises rock asphalt, base asphalt, stabilizer, nano vitrified microbeads, and the rock asphalt is 5% in the rock asphalt modified asphalt percentage, and the base asphalt is in The rock bitumen modified asphalt percentage is 92.8%, the stabilizer is 0.8% in the rock bituminous modified asphalt, and the nano vitrified microbead is 7% in the rock bituminous modified asphalt; The aggregate is one or a combination of limestone, volcanic rock, andesite; the filler is silica; the coupling agent is a titanate coupling agent, a silane coupling agent, or a zirconium coupling agent at least one or a combination thereof.

[0040] In addition, the preparation method of the rock asphalt modified asphalt: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com