Wire cutting device, wire transport system, and method for partitioning a wire electrode in an EDM machine

A conveying system and wire cutting technology, which is applied in the field of cutting such wire electrodes and wire cutting devices, can solve problems such as high shear strength wear, and achieve the effects of simple wear, reduced quantity, and low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

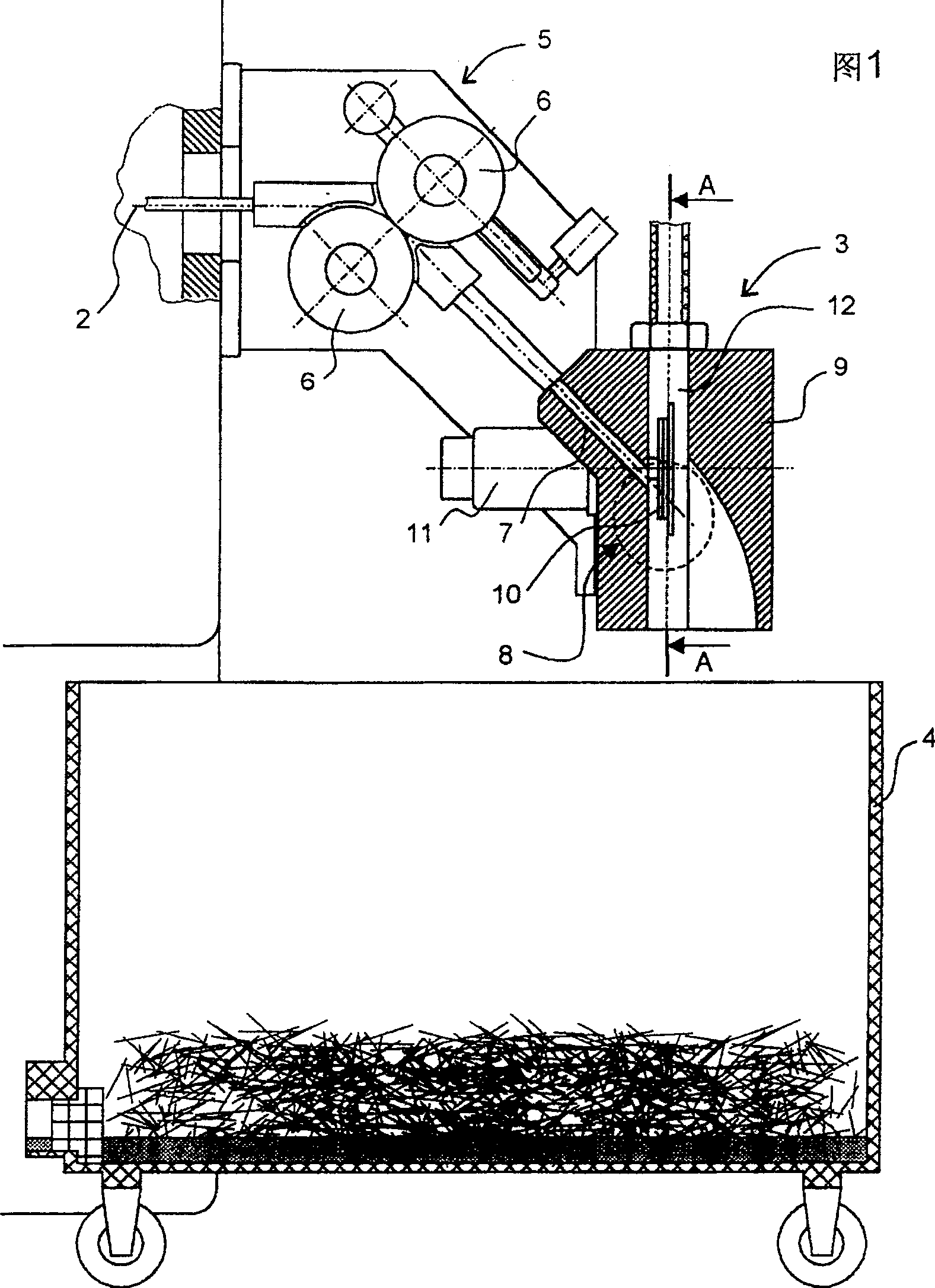

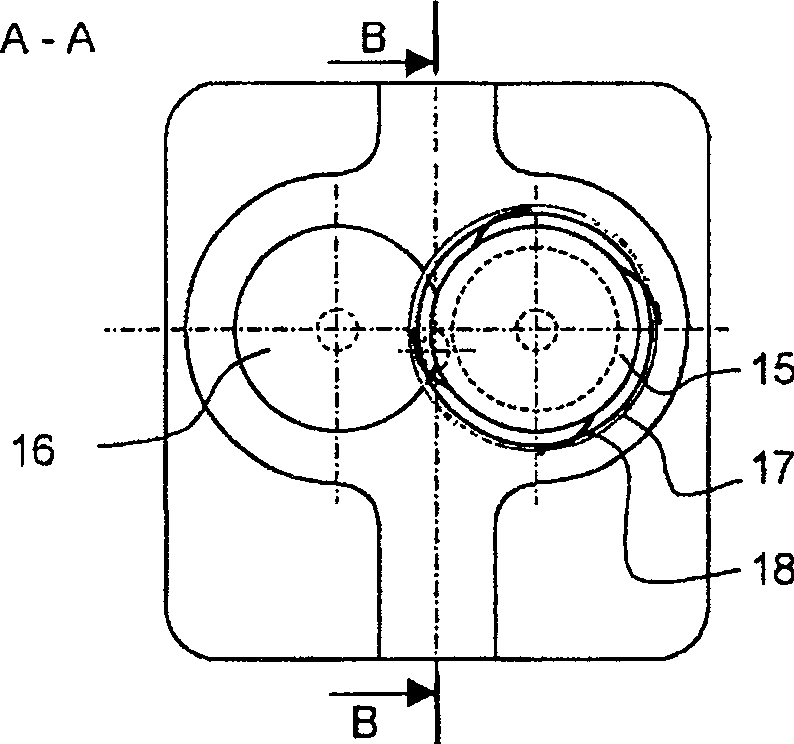

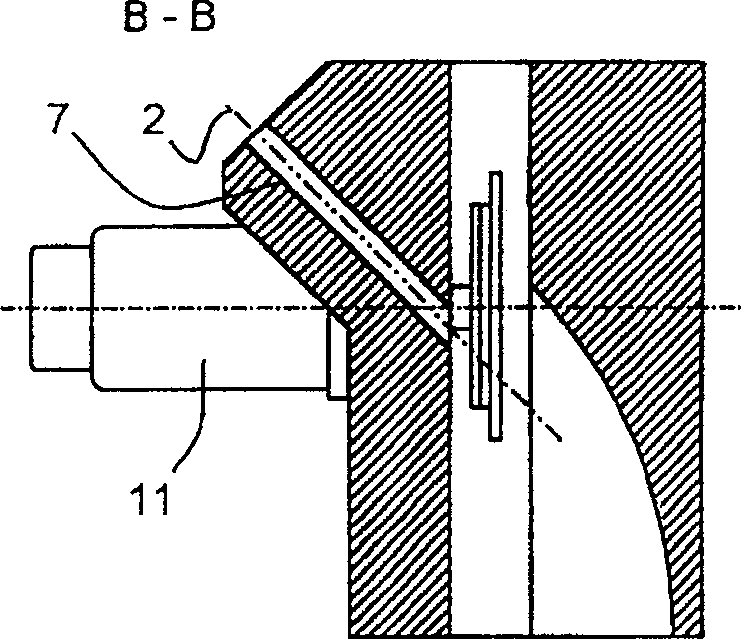

[0039] FIG. 1 shows a section of the wire delivery system of an EDM machine. The wire transport system transports the wire electrode 2 through the working area of the EDM machine, in which a spark discharge is generated by means of the wire electrode 2 , thereby removing material from the workpiece. The wire electrode 2 also undergoes material removal, so that the wire electrode 2 is worn out in the working area even for a short time so that it cannot be used for workpiece machining. For this reason, the wire electrode 2 is continuously guided through the working area and then treated in the treatment area during the machining of the workpiece. Located in the disposal area is a wire cutting device 3 which cuts the used wire electrode 2 into wire segments and collects the wire segments in a disposal container 4 for subsequent disposal.

[0040] FIG. 1 shows the wire delivery system of the wire extraction device 5 , which pulls the wire electrode 2 through the working area an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com