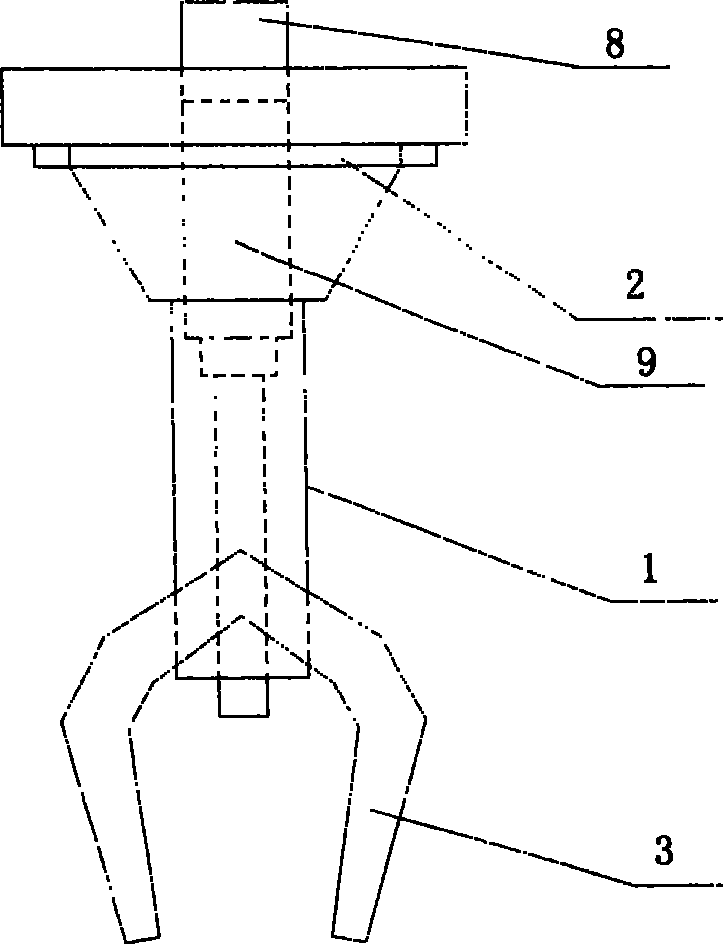

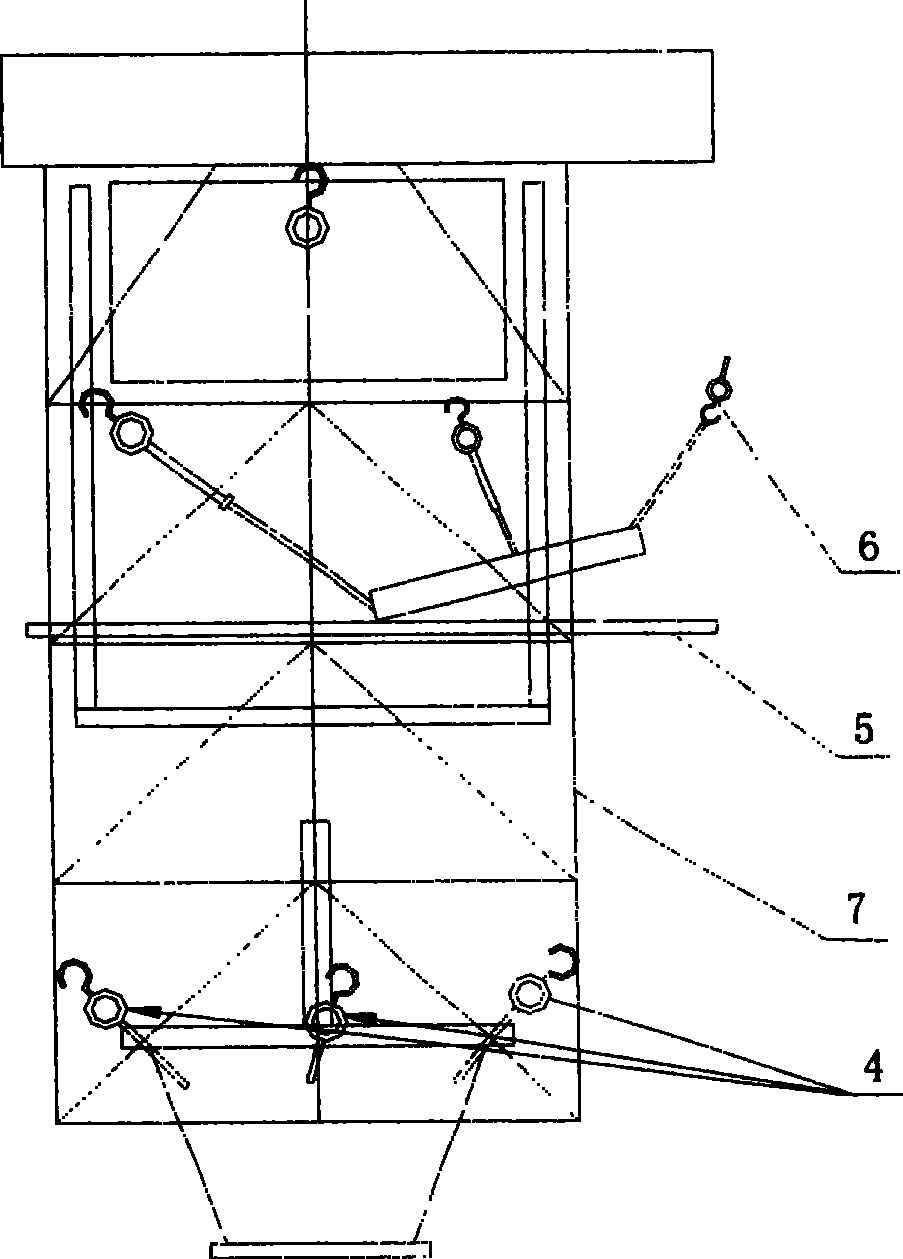

Construction method for disintegrating tongs and swivel supported large gear ring of stripping lifter without leaving machine

A technology of rotating support and construction method, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of high cost of machinery use, achieve the effects of shortening the construction period, reducing construction time and labor intensity, and saving hydraulic oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Using the above-mentioned construction method to replace the large ring gear of the 50-ton despindle crane, it took about 6 days and a total of 24 construction workers. Because the disassembly of the clamp body assembly was reduced, the mechanical parts were basically not replaced.

Embodiment 2

[0041] Using the above-mentioned construction method to replace the large ring gear of the 40-ton despindle crane, it took about 5 days, which was about 1 day shorter than the previous replacement. No mechanical parts have been replaced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com